Lubricated High Pressure Piston Air Compressors. Productivity from 3.0 to 2400 m3/min

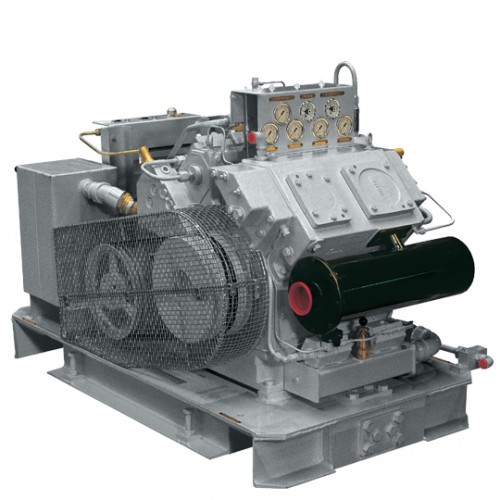

The high quality and application of the latest technology has enabled Gardner Denver's piston compressors to gain widespread popularity around the world. When designing and developing compressors, much attention is paid to increasing productivity and reliability when lowering the temperature of the output compressed air with the help of high-performance coolers and separators. The technical downtime and operating costs are reduced due to the quick and easy access to all components.

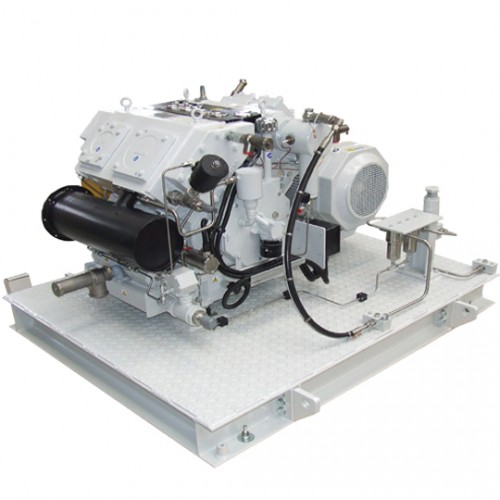

We introduce multi-stage piston compressors of the V-shaped or W-shaped configuration with air or water cooled and with a wide range of operating pressure up to 414 bar.

Click to view specificationsGas compression

Gardner Denver Compressors are designed for compression of various gases, depending on the application. Typically, it is argon, carbon dioxide, carbon monoxide, ethane, ethylene, helium, hydrogen, biogas, natural methane, nitrogen, nitrous oxide, helium oxide, sulfur fluoride and xenon.

Typical examples of the use of piston compressors are air jet switches, breathing air supply units, shaft compensation, engine starters, ship repairs, charging of hydraulic accumulators, manufacturing of plastic bottles and cans, test benches, vulcanization of tires, supply of compressed air for presses and actuators mechanisms

Piston compressors with air or water cooled

One of the great features of the compressors is the ability to apply both air and water type cooling on multi-stage compressors of high productivity (with engine power up to 250 kW) and high pressure.

Click to view specifications