Airlink Supervisor monitoring system

The development of compressor technology with the use of new hand-held digital control systems brings the process of control and management of compressor stations to a new level. Customers, installing modern compressor equipment in their production, want to get the most up-to-date information on the state of the equipment, operating parameters and current operating modes.

Compressors International, in keeping with the times, offers its customers a new product that meets customer requirements and improves the convenience of using compressor equipment. This is the Airlink Supervisor visualization and monitoring system developed by the engineers of Compressors International.

The innovative Airlink Supervisor monitoring system collects signals from all digital and analog sensors that are installed on the compressor station equipment, processes them and displays them on the monitor in the premises of the operator of the compressor or unit manager.

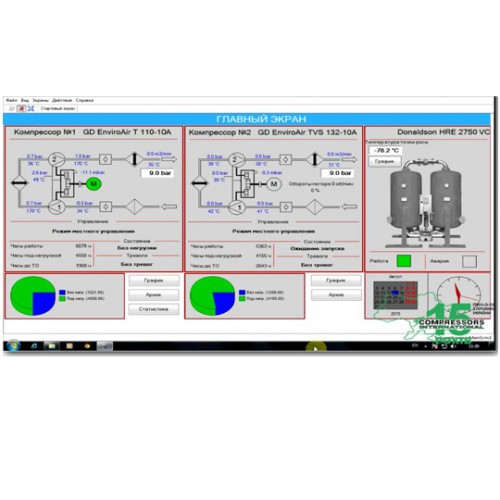

The program interface is the main window, which graphically depicts all equipment of the compressor station, including compressors, dehumidifiers and additional equipment. Each compressor is depicted as a set of icons for individual nodes, which enables the customer to control the whole process of air compression and to monitor the parameters of pressure and temperature of air from the suction valve to the discharge.

In addition, the state of the main electric motor, the position of the valves, the pressure, the temperature of the compressed air and, which is very important, the volume of compressed air produced by the compressor, is visually displayed. To monitor air quality, the Airlink Supervisor displays the dew point temperature of the compressed air.

For each of the control parameters, the system builds graphics in real time. The operator has an opportunity in a separate window to display a schedule for changing any parameter in time, with the ability to zoom in and out on the time axis.

For each of the monitored parameters, the system builds graphics in real time. The operator has the opportunity to display in a separate window the timetable for changing any parameter in time, with the possibility of zooming in and out on the time axis.

The Airlink Supervisor keeps track of equipment under load and in idle mode and displays all information in the form of pie charts. Thus, the customer always sees how much his equipment is loaded and what potential is available in the existing equipment for connecting new customers.

For each unit of equipment, the system tracks the emergence of emergencies and displays a warning message with an indication on the screen.

A distinctive feature of the Airlink Supervisor system is that using the GSM modem, station parameters are transmitted to the server at the office of the service company of Compressors International. Thus, service engineers of the company have an opportunity to react instantly to emergency situations in the work of equipment, as well as analysis of working parameters and planning of maintenance work.

All this increases reliability and ensures the trouble-free operation of the customer's compressor equipment, and, without exaggeration, brings the interaction with the customer and the relation to the equipment to a new high-tech level.