FourCore (FC) - efficiency from 21,21 to 47,98 m3/min

The ESM/VS 110-290 FC series from Gardner Denver is manufactured using the unique, state-of-the-art FourCore technology. The series comprises of bestin-class premium efficiency 2-stage oil lubricated compressors across the range of 110-250kW.

The ESM/VS 110-290 FC series includes powerful, energy-efficient compressors with a maximum capacity range of 21.21 to 47.98 m3/min. These are energy-efficient models of the ESM series with fixed speed and VS series with variable speed, The series is designed for efficient operation and is focused on long-lasting performance for important industrial processes.

The Gardner Denver ESM / VS 110-290FC compressors series have been developed with state-of-the-art technology, innovation and engineering.

All compressors of the ESM / VS 110-290 FC series have such advantages as:

- Silent operation with extremely low noise level,

- Compact design with small footprint,

- High performance and energy efficiency,

- Easy maintenance and long service intervals.

Reliability of Gardner Denver screw compressors

The ESM / VS 160-290FC series are manufactured in accordance with ISO standards, which meet the stringent industrial quality standards. All compressors of ESM / VS 160-290FC series equipped with modern and reliable GD Air End.

Gardner Denver Air Ends are designed to achieve the highest possible standards of efficiency. Time proven reliability of the Gardner Denver Screw compressors and legendary quality ensure reliable operation and easy maintenance.

FourCore technology - the power of four!

Gardner Denver team of application engineers has developed a premium, efficient, two-stage, constant-speed, variable-speed compressor model based on a new technology - the compact two-stage compression head. What makes this design unique is that the compression head is equipped with 1 electric motor and 4 rotors mounted in one semi-integrated housing. This design distinguishes itself from traditional two-stage compressors by its compact size and high energy efficiency. The new compressor head design makes these machines comparable in size to single-stage compressors.

Best-in-class efficiency & energy savings

New generation FourCore airend technology

✓ Very compact & very low weight

✓ Highest efficiency

✓ Semi-Integration of the oil filter, oil stop valve, oil distribution system, and oil temperature valve:

- less hoses and hydraulic pipes ➞ less costs

- no leakages

✓ High flexibility by a 2-step drive gear configuration ➞ UNIQUE to Gardner Denver

- constant interstage pressure ➞ better efficiency

- compact design

✓ Designed to implement in current ESM/VS Series ➞ UNIQUE to Gardner Denver

✓ Fixed and variable speed versions possible

✓ 10 years warranty

10 Years Warranty Protect 10

The Gardner Denver Protect 10 Warranty and Service programmes

will protect you up to 44,000 hours/10 years1]. It is one of the

most generous warranties available in the industry affording you total piece of

mind.

The Gardner Denver Protect 10 Warranty and Service programmes

will protect you up to 44,000 hours/10 years1]. It is one of the

most generous warranties available in the industry affording you total piece of

mind.

- The Protect 10 warranty is totally free to the compressor

owner2]

- The Gardner Denver authorised service provider will

deliver a guaranteed quality of service

- The Protect 10 service agreement underpinning the warranty will enable accurate maintenance, budgeting and cost of ownership

- The use of genuine Gardner Denver parts and lubricants will maximise compressor life and efficiency

1] Warranty duration is limited to 6 years/44,000 hours on the whole package, 10 years/44,000 hours on the air end. Whichever is the soonest.

2] Subject to Terms & Conditions

Gardner Denvergenuine spare parts

Genuine Gardner Denver parts and lubricants ensure that compressed air plant reliability and efficiency is maintained at the highest standards. Gardner Denver spare parts and lubricants are distinguished by:

Genuine Gardner Denver parts and lubricants ensure that compressed air plant reliability and efficiency is maintained at the highest standards. Gardner Denver spare parts and lubricants are distinguished by:

- Long service life, even under harshest conditions

- Minimum losses contributing to energy savings

- High reliability improves plant up-time

- Products manufactured with the strictest Quality Assurance Systems

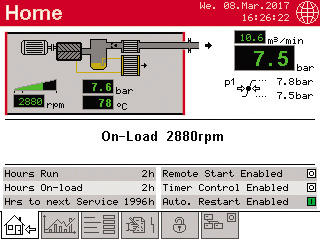

GD Pilot TS compressor controller with innovative touch screen

Most advanced controller GD Pilot TS, with its high quality touchscreen, is an extremely simple device that is self-explanatory. All functions are clearly structured in five main menus and are intuitive. The multilingual GD Pilot TS control system ensures reliable operation and justifies the investment spent on its purchase, constantly monitors operational parameters, which is the key to lower operating costs.

iConn Compressed

Air Service 4.0

![]() The ESM/VS Series is equipped with iConn as standard. iConn is the smart, proactive real-time monitoring service that delivers in-depth and realtime knowledge on the system to our compressed air users. It enables accurate production planning and total peace-of-mind, generating insight and statistics that keep users informed on performance, and at the same time highlighting potential issues before they become a problem.

The ESM/VS Series is equipped with iConn as standard. iConn is the smart, proactive real-time monitoring service that delivers in-depth and realtime knowledge on the system to our compressed air users. It enables accurate production planning and total peace-of-mind, generating insight and statistics that keep users informed on performance, and at the same time highlighting potential issues before they become a problem.

- Advanced remote analysis

- Predictive – evaluates historic data

- Maximises energy efficiency

- Optimises compressor performance

- Reduces downtime

- Works as an open standard

- Free on new compressors – can be retrofitted

- Proactive maintenance

Variable Speed Compressors - VS Series

VS Series variable speed compressors effectively meet the varying compressed air requirements for your compressed air systems.

These designed to meet up to 45% reduction of the energy consumption compared to compressors with fixed speed.

The compressors are equipped with a highly efficient and energy-saving electric motor to reduce plant’s carbon footprint.

FC-series models have improved efficiency compared to standard models in their class – 8-10% higher energy efficiency compare to a single-stage compressors.

Gardner Denver’s innovative new FourCore technology delivers greater efficiency in a low weight and compact size. The series comprises of bestin-class premium efficiency 2-stage oil lubricated compressors across the range of 110-250kW. In some cases, payback times can be less than a year, delivering a fantastic return on investment and incredible energy savings to the user.

Gardner Denver create solutions that help customers save energy – including products that are fuel-efficient, aid in heat recovery, and reduce waste wherever possible.

The new ESM/VS 110FC to 290FC range delivers a major breakthrough in compressor technology and provides enhanced levels of efficiency to offer evenmore energy savings, reducing CO2 waste.

Features of the advanced compressors from Gardner Denver:

- Rotary screw compressors ESM 160e - 290e

- The ESM e-series compressors are super-efficient and provide energy savings.

- VS Series Variable Speed Compressors - Maximum efficiency throughout the entire operating range.

- Gardner Denver compressors are equipped with the GD Pilot TS Controller.

- Option (heat recovery of Gardner Denver compressors).

ESM 110-290FC - Fixed Speed Screw Compressors

Model |

Nominal Pressure |

Drive Motor |

FAD 1] |

Noise Level 2] |

Weight |

DimensionsL x W x H |

|

bar g |

kW |

m3/min |

dB(A) |

kg |

mm |

||

|

|

7.5 | 24.05 | 2907 x 2071 x 2193 |

||||

ESM110FC |

8.5 | 110 | 22.56 | 72 | 4483 | ||

|

|

10 | 21.21 | |||||

|

|

7.5 | 28.79 | |||||

ESM132FC |

132 | 25.27 | 73 | 4498 | |||

| 8.5 | |||||||

|

|

10 | 25.24 | |||||

ESM160FC |

7.5 | 160 | 33.67 29.14

|

75 75

|

4542 | ||

| 10 | |||||||

ESM200FC |

7.5 | 200 | 40.09 | 76 | 4765 | ||

| 10 | 35.64 | 76 | |||||

ESM250FC |

7.5 | 250 | 42.62 | 77 | 4975 | ||

| 10 | 38.69 | 77 | |||||

ESM290FC |

7.5 | 250 | 47.84 | 78 | 5000 | ||

| 10 | 45.08 | 78 |

VC 110-290FC - Variable Speed Screw Compressors

Model |

Nominal Pressure |

Drive Motor |

FAD 1]

|

Noise Level 2]

|

Weight |

Dimensions

|

bar g |

kW |

m3/min |

dB(A) |

kg |

mm |

|

VS110FC |

6 - 10 | 110 | 9.1 - 24.69 | 72 | 4672 | 2907 x 2071 X 2193 |

|

VS132FC |

6 - 10 |

132 |

9.16 - 29.39 |

72 |

4736 |

|

|

VS160FC |

5 - 10 |

160 |

9.61 - 32.07 |

74 |

4783 |

|

|

VS200FC |

5 - 10 |

200 |

9.37 - 39.14 |

76 |

5083 |

|

|

VS250FC |

5 - 10 |

250 |

9.37 - 42.97 |

77 |

5253 |

|

|

VS290FC |

5 - 10 |

250 |

9.37 - 47.98 |

78 |

5268 |

1]

Data measured and stated in accordance with ISO 1217, Edition 4, Annex C and Annex

E and the following conditions: Air Intake Pressure 1 bar a, Air Intake

Temperature 20°C, Humidity 0 % (Dry).

2]

Measured in free field conditions in accordance with ISO 2151, tolerance ± 3dB (A).