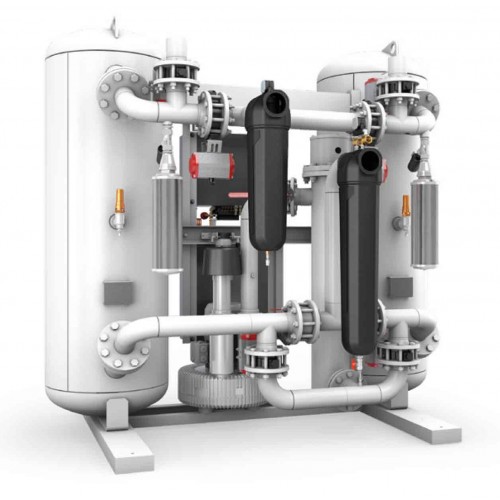

Heated Blower Desiccant Air Dryers 8-249 m cub /min

The GDHB models are an extremely energy-efficient, compact and reliable system for efficient continuous compressed air drying and purification in large volumes.

The principle of operation of the models is as follows: after the compressor, the air is filtered and enters one of the vertical tanks, where it is dehumidified by adsorption. At the same time, the adsorbent is regenerated in the second tank. This is due to the supply of heated air from the outside by a blower, which removes excess moisture from the adsorbent. After regeneration, the heater is turned off, and the external blower cools the tower and the adsorbent with air. After that, the cycle is reversed: the tower that was previously regenerating now adsorbs moisture, and the tower that was previously adsorbing now regenerates the adsorbent.

Advantages of the GDHB-TLS series:

- The blower is located outside and uses uncompressed air for regeneration

- Energy management system (EMS) maximises energy efficiency

- Soft starters increase blower service life

- Model design ensures low pressure drop

- The heater and blower are controlled by a temperature controller to operate at maximum energy efficiency

- Increased protection class for electrical components IP54

- Additional options allow the dehumidifiers to be configured to meet individual needs of the air system

New dryers offer the state-of-the-art Energy Management System (EMS) that maximises energy

efficiency while maintaining a constant dew point. By using a humidity sensor to continuously monitor the

dew point, EMS minimises the compressed air used in regeneration, and optimises heater and blower operation

Heated blowers are equipped with solid state soft starters that limit inrush current to ensure a smooth start

and longer blower motor life.

The dryers are engineered for low pressure drop through valve selection, tower size and filter design.

The heater and blower are controlled by the outlet regeneration temperature that shuts off to save electrical

power once desiccant has been thoroughly regenerated.

Solid state relays provide precise heater control, reduced heating times and extended heater life.

Technical data

|

Model |

Connection Size |

Capacity |

Weight |

Dimensions |

|||

|

mm |

|||||||

|

m3/h |

m3/min |

kg |

Depth |

Width |

Height |

||

|

GDHB83TLS |

2" |

500 |

9 |

670 |

995 |

1,336 |

1,755 |

|

GDHB150TLS |

2" |

900 |

16 |

958 |

1,096 |

1,477 |

2,186 |

|

GDHB183TLS |

3" |

1,100 |

18 |

1,258 |

1,398 |

1,718 |

2,188 |

|

GDHB233TLS |

3" |

1,400 |

25 |

1,451 |

1,398 |

1,718 |

2,188 |

|

GDHB300TLS |

3" |

1,800 |

31 |

1,710 |

1,484 |

2,080 |

2,016 |

|

GDHB366TLS |

3" |

2,220 |

37 |

1,857 |

1,484 |

2,080 |

2,016 |

|

GDHB433TLS |

3" |

2,600 |

45 |

2,504 |

1,860 |

2,622 |

2,357 |

|

GDHB533TLS |

DN100 PN16 |

3,200 |

53 |

2,775 |

1,750 |

2,622 |

2,357 |

|

GDHB650TLS |

DN100 PN16 |

3,900 |

65 |

3,138 |

1,660 |

2,622 |

2,357 |

|

GDHB750TLS |

DN150 PN16 |

4,500 |

75 |

|

1,949 |

3,054 |

2,541 |

|

GDHB883TLS |

DN150 PN16 |

5,300 |

89 |

4,417 |

1,949 |

3,054 |

2,541 |

|

GDHB1166TLS |

DN150 PN16 |

7,000 |

119 |

5,524 |

2,120 |

3,407 |

2,350 |

|

GDHB1550TLS |

DN150 PN16 |

9,300 |

155 |

6,072 |

2,312 |

3,779 |

2,462 |