Productivity from 8,25 to 14,8 m3/min

Models ESM / VS 55-75 series are specially designed for continuous round-the-clock operation. An efficient engine, actuator and screw unit combination reduces the specific compressor power. As an added benefit, customers receive energy savings. High-performance TEFC IP55 motors are installed on the Gardner Denver equipment. The engine's automatic lubrication system increases the bearings' service life and eliminates the need for maintenance.

Thanks to the use of a high-precision screw unit with optimum speed, the rotor's edge was able to improve the compressor's efficiency and reduce the noise level. This reduces the power consumption by 8% for ESM 55/75.

The ESM/VS 55-75 and ESM 55-75e series models can be equipped with an integrated dryer, which will save space and time, as well as improve energy efficiency and compressed air quality.

The Gardner Denver ESM / VS 55-75 compressor series have been developed with state-of-the-art technology, innovation and engineering.

All compressors of the ESM / VS 55-75 series have such advantages as:

- Silent operation with extremely low noise level,

- Compact design with small footprint,

- High performance and energy efficiency,

- Easy maintenance and long service intervals.

Reliability of Gardner Denver screw compressors

The ESM / VS 55-75 series are manufactured in accordance with ISO standards, which meet the stringent industrial quality standards. All compressors of ESM / VS 55-75 series equipped with modern and reliable GD Air End.

Gardner Denver Air Ends are designed to achieve the highest possible standards of efficiency. Time proven reliability of the Gardner Denver Screw compressors and legendary quality ensure reliable operation and easy maintenance.

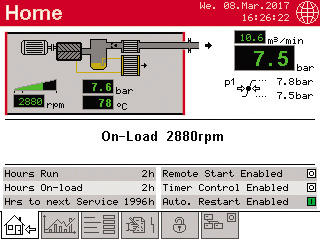

GD Pilot TS compressor controller with innovative touch screen

Most advanced controller GD Pilot TS, with its high quality touchscreen, is an extremely simple device that is self-explanatory. All functions are clearly structured in five main menus and are intuitive. The multilingual GD Pilot TS control system ensures reliable operation and justifies the investment spent on its purchase, constantly monitors operational parameters, which is the key to lower operating costs.

Variable Speed Compressors - VS Series

VS Series variable speed compressors effectively meet the varying compressed air requirements for your compressed air systems.

These designed to meet up to 45% reduction of the energy consumption compared to compressors with fixed speed.

The compressors are equipped with a highly efficient and energy-saving electric motor to reduce plant’s carbon footprint.

Energy efficient E-series models - the best energy efficiency solution on the market!

E-series models have improved efficiency compared to standard models in their class – it is more than 5% higher energy efficiency. Thanks to new innovative technologies from Gardner Denver, namely the IE4 electric motor, the automatic oil level control valve, the heavy-duty screw element, the models of this energy-efficient series can provide additional energy savings in the equivalent to 7,000 euros per year.

E-series models have improved efficiency compared to standard models in their class – it is more than 5% higher energy efficiency. Thanks to new innovative technologies from Gardner Denver, namely the IE4 electric motor, the automatic oil level control valve, the heavy-duty screw element, the models of this energy-efficient series can provide additional energy savings in the equivalent to 7,000 euros per year.

The efficient electric motor / drive / Air end combination is designed to reduce power consumption, which provides the benefit of energy savings. In addition, the compressors of the series (e) are equipped with IE4 high efficiency motors. E Series models offer higher performance for maximum efficiency. Variable speed models save energy consumption by reducing energy cost up to 45%. Gardner Denver Air Ends are designed to achieve the highest possible standards of efficiency. Time proven reliability of the Gardner Denver Screw compressors and legendary quality ensures reliable operation and easy maintenance.

Bigger in size, High performance Air Ends with lowest possible rotational speed, reduce energy costs.

Features of the advanced compressors from Gardner Denver:

- The ESM e-series compressors are super-efficient and provide energy savings.

- VS Series Variable Speed Compressors - Maximum efficiency throughout the entire operating range.

- Gardner Denver compressors are equipped with the GD Pilot TS Controller.

- Option (heat recovery of Gardner Denver compressors).

ESM 55 – 75 Fixed Speed Screw

Compressors

Integrated Dryer Option

|

Gardner Denver Model |

Nominal Pressure |

Drive Motor |

FAD 1] |

Noise Level 2] |

Weight |

Dimensions |

|

Dimensions |

Pressure Dew |

Weight |

|

bar g |

kW |

m3/min |

dB(A) |

kg |

mm |

|

mm |

C |

kg |

|

|

ESM55 |

7.5 10 13 |

55 |

10.71 9.50 8.25 |

69 |

1405 |

1958 x 1138 x 1857 |

|

2458 x 1138 x 1857 |

3 |

233 |

|

ESM75 |

7.5 10 13 |

75 |

13.98 12.54 10.50 |

72 |

1495 |

1958 x 1138 x 1857 |

|

2458 x 1138 x 1857 |

3 |

233 |

|

ESM55е |

7.5 10 |

55 |

10.71 9.57 |

69 |

1406 |

1958 x 1138 x 1857 |

|

2458 x 1138 x 1857 |

3 |

233 |

|

ESM75е |

7.5 10 |

75 |

14.80 12.70 |

71 |

1785 |

1958 x 1138 x 1857 |

|

2458 x 1138 x 1857 |

3 |

233 |

VS 55 – 75 Variable Speed Screw

Compressors Integrated Dryer Option

|

Gardner Denver Model |

Nominal Pressure |

Drive Motor |

FAD1]] |

Noise Level 2] at 100% Load |

Weight |

Dimensions L x W x H |

|

Dimensions |

Pressure Dew Point 3] |

Weight |

|

bar g |

kW |

m3/min |

dB(A) |

kg |

mm |

|

mm |

C |

kg |

|

|

VS55 |

5 - 10 |

55 |

2.50 - 10.99 |

69 - 72 |

1430 |

1958 x 1138 x 1857 |

|

2458 x 1138 x 1857 |

3 |

233 |

|

VS75 |

5 - 13 |

75 |

2.10 - 14.03 |

72 - 74 |

1520 |

1958 x 1138 x 1857 |

|

2458 x 1138 x 1857 |

3 |

233 |

1] Data measured and stated in accordance with ISO

1217, Edition 4, Annex C and Annex E and the following conditions:

Air Intake

Pressure 1 bar a, Air Intake Temperature 20°C, Humidity 0 % (Dry).

2] Measured in free field conditions in accordance

with ISO 2151, tolerance ± 3dB (A). All models are available in water cooled

versions.

3] Data refer to ISO 7183, working pressure of 7

bar, inlet temperature 35°C and ambient temperature 25°C.