Description 2-stage oil-free screw air compressor Gardner Denver EnviroAire T132 A350028022

In today's industrial world, where product quality and operational efficiency determine business competitiveness, choosing the right compressor equipment becomes a critically important decision. Gardner Denver's EnviroAire T/TVS 90-160 compressors with innovative 2-stage oil-free screw compression technology represent a new standard in clean compressed air production, combining Class 0 certified quality with unmatched energy efficiency.

These oil-free rotary screw compressors are designed for enterprises where even the slightest oil contamination of air can lead to catastrophic consequences: product spoilage, production shutdowns, brand reputation damage, and enormous financial losses. Pharmaceutical industry, food production, electronics industry, medical equipment manufacturing – all these sectors require absolutely clean air, and this is where EnviroAire compressors demonstrate their unique capabilities.

ISO 8573 Class 0 Certification: Absolute Air Purity

The Highest Quality Standard

EnviroAire T/TVS 90-160 compressors have TÜV certification according to ISO 8573 Class 0 standard – the most stringent class of compressed air quality in the world. This is not just a marketing claim, but an officially confirmed guarantee that the content of oil and oil vapors in the produced air is less than 0.01 mg/m³.

What Does Class 0 Certification Mean?

ISO 8573 classification defines compressed air purity levels according to three parameters: solid particles, water, and oil. Class 0 is the highest category, which goes beyond Class 1, guaranteeing that the air is practically perfectly clean. For comparison:

- Class 1: oil content < 0.01 mg/m³

- Class 0: technically zero oil content, confirmed by independent testing

Protection Against Critical Risks

Using compressors with Class 0 certification eliminates the following risks:

- Product spoilage due to oil contamination

- Quality standard violations in pharmaceutical and food industries

- Coating defects in automotive and electronics sectors

- Brand reputation damage due to quality issues

- Financial losses from product batch rejection

- Increased costs for air filtration and purification

Innovative 2-Stage Compression Technology

Optimized Screw Element Design

The heart of EnviroAire compressors is the optimized 2-stage oil-free screw element (airend), representing a revolutionary design that ensures maximum efficiency and reliability.

2-Stage Compression Operating Principle

Unlike single-stage compressors, where air is compressed in one pass, the 2-stage system works as follows:

- First Stage: Air is drawn in and pre-compressed to intermediate pressure

- Intercooling: Compressed air is cooled, increasing efficiency

- Second Stage: Pre-compressed air reaches final operating pressure

Advantages of 2-Stage Design

- 14% higher energy efficiency compared to industry standard

- 9% greater productivity with the same energy consumption

- Up to 8% higher volumetric flow compared to competitors

- Lower compression temperature, extending component service life

- Reduced load on each stage, increasing reliability

Sealed Drive System

The 2-stage compression element is designed as a sealed, maintenance-free drive system. This means:

- No need for regular intervention in the mechanism

- Minimized contamination risk

- Increased operational reliability

- Reduced maintenance costs

UltraCoat™ Technology: Protection and Durability

Advanced Protective Coating

Gardner Denver applies exclusive UltraCoat™ technology – an advanced rotor and housing protection process that provides the strongest coating in the industry.

UltraCoat™ Characteristics

- Mechanical bonding: Coating is not just applied, but mechanically integrated with the surface

- Unmatched adhesive properties: Coating does not delaminate even under extreme loads

- High thermal resistance: Withstands temperature fluctuations without degradation

- Anti-corrosion protection: Prevents oxidation and surface corrosion

Stainless Steel Rotor

UltraCoat is applied in combination with a second-stage stainless steel rotor, creating a synergistic effect:

- Stainless steel provides natural corrosion resistance

- UltraCoat adds an additional protective layer

- The combination guarantees maximum durability

- Efficiency preservation throughout the entire service life

Protection Against Performance Degradation

Thanks to UltraCoat™, the rotor assembly maintains its geometric parameters for many years of operation, preventing:

- Volumetric flow reduction

- Pressure drop

- Increased energy consumption

- Premature wear

Fixed and Variable Speed Models

T Series (Fixed Speed): Reliability and Simplicity

Fixed speed compressors are ideal for applications with stable air consumption:

- Constant productivity

- Simple operation

- Excellent price/quality ratio

- Proven reliability

TVS Series (Variable Speed): Maximum Efficiency

Variable speed (VSD) compressors represent the pinnacle of technological perfection:

IE5 Ultra-Premium Class Motors

TVS models use high-efficiency IE5 motors according to IEC 60034-30-2 classification. These are:

- The highest motor efficiency class in the world

- Minimum energy losses at any load

- World-class efficiency throughout the entire operating range

Hybrid Reluctance Motor (HRM)

Revolutionary IE5 hybrid reluctance motor technology provides:

- Wide turndown ratio – up to 71%

- Ability to shut down immediately at minimum speed

- Complete elimination of unloaded operation (unloaded mode)

- Real-time adaptation to consumption fluctuations

Integrated Variable Speed Drive

The Power Drive System (PDS) exceeds IES2 EN61800-9 class requirements:

- Matched drive and motor for maximum efficiency

- Optimization at all operating modes

- High energy savings across a wide flow range

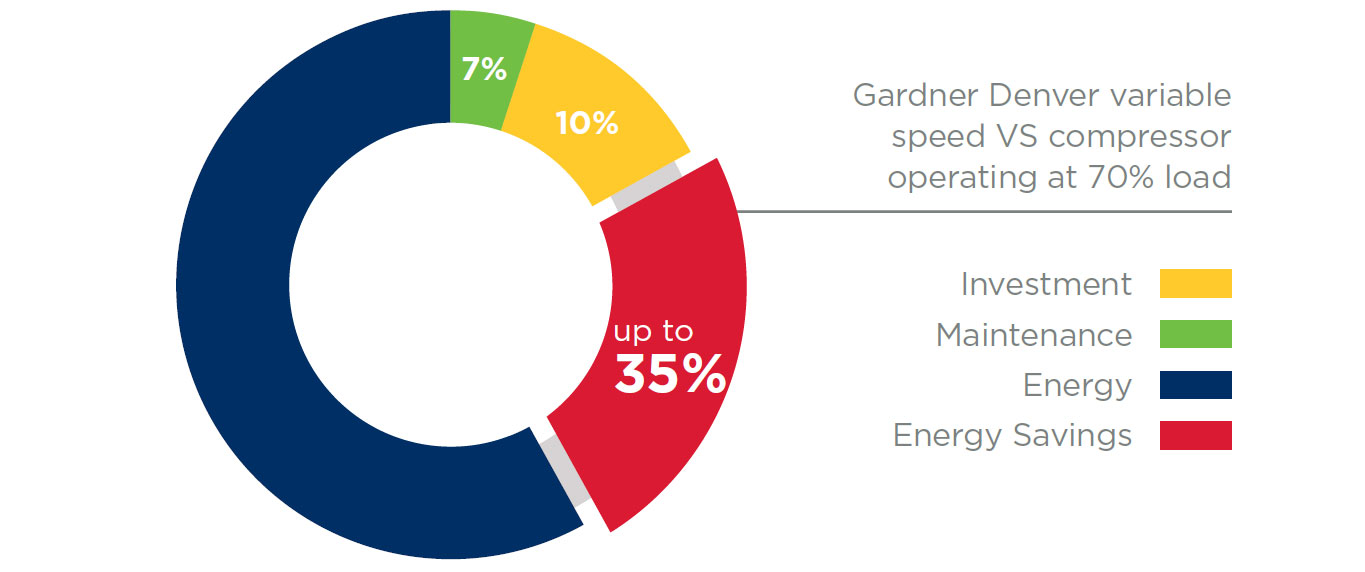

Up to 35% Energy Savings

TVS models provide savings up to 35% compared to traditional fixed speed compressors, which with high electricity costs allows recovering additional investment within 1-2 years.

Technical Specifications and Operating Ranges

Power Range: 90-160 kW

The EnviroAire T/TVS series covers a range from 90 to 160 kW, allowing selection of the optimal model for enterprises of various scales.

Operating Pressure: 7.5-10.5 bar

Specialized models available at different pressure levels:

- 7.5 bar: For low-pressure applications

- 8.5 bar: Universal standard pressure

- 10.5 bar: For high-pressure processes

Volumetric Flow: 6.7-28.3 m³/min

A wide productivity range from 6.7 to 28.3 m³/min allows meeting the needs from small specialized lines to large production complexes.

Cooling Configurations

Air Cooling

- No water supply required

- Simple installation

- Ideal for facilities with limited infrastructure

- Possibility of rooftop or outdoor installation

Water Cooling

- Higher cooling efficiency

- More compact dimensions

- Lower noise level

- Water jacketed air end cooling

- Possibility of heat recovery integration

High Temperature Operation

Compressor systems are designed to operate at ambient temperatures up to 46°C, ensuring:

- Additional cooling margin

- Reliability in hot climatic conditions

- Possibility of placement in non-air-conditioned spaces

Intelligent Control: Governor 10

New Advanced Controller

Governor 10 is the brain of the compressor system, offering:

Real-Time Information

- Current operating parameters

- Status of all systems

- Warnings about deviations from normal

User-Friendly Interface

- Intuitive menu

- Graphical data presentation

- Multi-language support

Graphical Trending Function

- Historical data visualization

- Trend analysis

- Expert knowledge about compressor operation

- Operating mode optimization

Energy Monitoring

Optional energy monitoring system displays:

- Energy consumption (kWh) in real-time and cumulatively

- Electricity cost accounting for tariffs

- Operating efficiency (specific energy consumption)

- Comparison with reference indicators

This data allows:

- Identifying non-optimal operating modes

- Justifying investment in modernization

- Tracking effects from adjustments

- Planning electricity budget

iConn System: Compressed Air Service 4.0

Proactive Real-Time Monitoring

All T/TVS series compressors are standard equipped with iConn system – this is a revolutionary approach to compressor equipment maintenance.

Intelligent Analytics

iConn provides:

- Continuous data collection on all operating parameters

- Remote monitoring through cloud platform

- Deep system knowledge based on Big Data

- Extended analysis by Gardner Denver experts

Predictive Maintenance

The system is Predictive because it:

- Evaluates historical operation data

- Identifies anomalies and deterioration trends

- Predicts potential failures

- Recommends preventive measures before problems occur

iConn Advantages

Energy Efficiency Maximization:

- Identification of non-optimal modes

- Adjustment recommendations

- Specific energy consumption monitoring

Performance Optimization:

- Control of compliance with specification characteristics

- Performance degradation detection

- Maintenance recommendations

Downtime Reduction:

- Warnings about future failures

- Maintenance planning at convenient times

- Elimination of unplanned shutdowns

Remote Support:

- Diagnostics without specialist visit

- Quick response to problems

- Reduced service costs

Open Standard and Free of Charge

iConn operates as an open standard:

- Free on new compressors

- Possibility to retrofit old models

- Integration with enterprise management systems

- No hidden fees

System Control: GD Connect 12 Plus

Multi-Compressor Operation Optimization

In most industrial applications, not one but several compressors are used, supplying air to a common header. To ensure maximum efficiency of such a system, an intelligent control system is necessary.

Connect 12 Plus Functions

Load Harmonization:

- Control of up to 12 compressors simultaneously

- Support for fixed and variable speed models

- Coordination of different equipment types

Pressure Optimization:

- Tightening the network pressure range

- Maintaining minimum required pressure

- Elimination of energy losses from excess pressure

Running Hours Equalization:

- Even load distribution

- Economical maintenance

- Increased uptime of entire fleet

Base Load Sequencing

Optional Base Load Sequencing module allows:

- Centralized control of up to four compressors

- Matching supply with actual demand

- Automatic unit start/stop

- Minimizing operation in inefficient modes

Energy Savings

Since energy is the largest cost factor of a compressor (up to 80% of total life cycle costs), the Connect 12 Plus system provides:

- 10-20% reduction in electricity consumption

- Elimination of simultaneous loaded/unloaded operation

- Optimal compressor selection for current load

PureCare Service Programs

Specialized Service for Oil-Free Equipment

PureCare programs go beyond traditional service schemes, being specifically designed for the oil-free product range.

PureCare Purpose

- Ensuring uninterrupted supply of quality compressed air

- Maintaining optimal compressor performance

- Preserving Class 0 certification throughout the entire service life

- User peace of mind regarding air quality

Execution by Factory-Trained Technicians

PureCare service plans are executed by factory-trained technicians:

- Deep knowledge of compressor design

- Understanding of oil-free system specifics

- Use of correct procedures

- Adherence to Gardner Denver quality standards

Exclusively Genuine Parts

PureCare involves using only genuine Gardner Denver parts:

Why Is This Important?

Long Service Life:

- Genuine parts are specifically designed for these compressors

- Withstand the most severe operating conditions

- Maintain characteristics throughout entire service life

Minimum Losses:

- Precise filter geometry minimizes pressure drop

- Quality seals prevent air leakage

- Efficient heat exchangers reduce energy consumption

Quality Guarantee:

- Production according to strictest quality assurance systems

- Certification of standards compliance

- No contamination risk

Service Agreement Benefits

Reduced Ownership Costs:

- Most cost-effective solutions

- Individual maintenance strategy

- Prevention of expensive emergency repairs

- Maintenance budget planning

Increased Uptime:

- Reduction of unplanned downtime

- Prevention before problems occur

- Quick response when needed

Peak System Efficiency:

- Proper maintenance maintains efficiency

- Regular inspections identify deviations

- Timely replacement of consumables

Extended Warranty:

- Duration depends on contract term

- Peace of mind regarding unforeseen expenses

- Confirmation of service quality

Heat Recovery: Profitable Investment

94% of Energy Converted to Heat

One of the least obvious but most profitable aspects of compressor systems is that approximately 94% of the energy required to operate the compressor is converted to heat.

Heat Recovery Option

For water-cooled models, an optional heat recovery system is available, allowing utilization of this heat for:

Hot Process Water

- Water heating for production processes

- Temperature up to 70-90°C

- Replacement of electric or gas boilers

Space Heating

- Production floor heating

- Office space heating

- Reduction of gas or electricity costs in winter

Pre-heating for Steam Generation

- Increased steam generator efficiency

- Reduction of primary fuel consumption

Payback Less Than 1 Year

Thanks to the high volume of recovered energy, heat recovery system investment payback typically is less than 1 year:

Calculation Example:

- 160 kW compressor operates 6000 hours/year

- Energy consumption: 960,000 kWh/year

- Heat recovered: 902,400 kWh/year (94%)

- At energy cost of 0.10 €/kWh, savings: 90,240 € per year

- Heat recovery system cost: 60,000-80,000 €

- Payback: 8-10 months

Environmental Responsibility

Heat recovery also:

- Reduces enterprise carbon footprint

- Increases overall energy efficiency

- Contributes to sustainable development goals

- Improves company environmental rating

Air Treatment: Comprehensive Solutions

Complete Range of Air Treatment Equipment

While EnviroAire compressors guarantee Class 0 for oil, modern processes require control of other air quality parameters as well. Gardner Denver offers a complete range of equipment for comprehensive compressed air treatment.

Filtration

Purpose: Removal of free water, dirt and aerosols

Filter Types:

- Coarse filters (removal of bulk water and dirt)

- Coalescing filters (aerosol removal)

- Microfilters (fine particulate removal)

Filtration Classes according to ISO 8573-1 for solid particles:

- Class 1: ≤0.1 μm, ≤0.1 mg/m³

- Class 2: ≤1.0 μm, ≤1.0 mg/m³

- Class 3: ≤5.0 μm, ≤5.0 mg/m³

Air Dryers

Adsorption Dryers:

- For ISO Dew Point Class 1, 2 and 3

- Dew point down to -70°C

- Applications in pharmaceutical and food industries

- Critical processes where moisture is unacceptable

Refrigerated Dryers:

- For ISO Dew Point Class 3 and 4

- Dew point +3°C to +10°C

- Most common solution for general industrial applications

- Effective price/quality ratio

Subfreeze Dryers:

- Dew point down to -20°C

- For applications in cold conditions

Carbon Towers

Purpose: Removal of oil vapor and hydrocarbons

Efficiency: Content reduction to 0.003 mg/m³ and less

Applications:

- Additional protection in critical processes

- Odor removal

- Purification from atmospheric pollutants

- Achievement of highest purity standards

Condensate Management

Condensate Traps:

- Electronic (with level sensors)

- Timer-based (periodic operation)

- Mechanical float (automatic no-loss)

Oil/Water Separators:

- For environmentally safe condensate disposal

- Oil and water separation

- Compliance with environmental standards

- Possibility of discharging purified water to sewage

Specialized Options and Modifications

Extreme Temperatures

For High Temperatures:

- Enhanced cooling

- Heat-resistant materials

- Modified ventilation systems

For Low Temperatures:

- Critical component heating

- Antifreeze fluids

- Special lubricants

High Dust Filtration

For operation in dusty environments:

- Reinforced air filters

- Pre-cleaning systems

- Extended filter service intervals

Outdoor Installation

Modifications for outdoor placement:

- Atmospheric precipitation protection

- Anti-corrosion coating

- Heating in cold periods

- Ventilation for hot climates

Pre-Engineered Solutions

Gardner Denver offers a wide selection of pre-engineered options, accelerating delivery and reducing the cost of custom solutions.

Ease of Maintenance

Service-Oriented Design

EnviroAire compressors are designed with ease of maintenance in mind:

Clear Access to Components:

- Filters located in easily accessible places

- Heat exchangers easily removable for cleaning

- Consumables grouped for convenience

Hinged Removable Doors:

- Quick opening for inspection

- Safe access to internal components

- Ergonomic design

Standardized Components:

- Use of widely available parts where possible

- Reduction of spare parts waiting time

- Simplified logistics

Automated Systems

Smart No-Loss Drain:

- Intelligent condensate drainage

- Minimization of compressed air losses

- Automatic operation only when necessary

Hydraulic Inlet Valve:

- Smooth airflow control

- Reliability and durability

- Minimum maintenance

Pneumatic Blowdown:

- Automatic system cleaning at shutdown

- Prevention of condensate accumulation

- Increased reliability

Application Industries

Pharmaceutical Industry

Critical Requirements:

- Absolute air purity (Class 0)

- GMP (Good Manufacturing Practice) compliance

- No product contamination risk

- Documentation and traceability

Applications:

- Tablet and capsule production

- Fermentation

- Drying

- Sterile product packaging

- Powder transportation

Food and Beverage Industry

Critical Requirements:

- Certification for food contact

- No oil and contaminants

- HACCP compliance

- Hygienic standards

Applications:

- Beverage bottling

- Product packaging

- Pneumatic ingredient transport

- Tank aeration

- Sorting and processing

Electronics Industry

Critical Requirements:

- No particles and aerosols

- Low dew point

- Parameter stability

- Cleanrooms

Applications:

- Microchip production

- Electronics assembly

- Board processing

- Coating application

- Pressure testing

Automotive Industry

Critical Requirements:

- Painting quality

- No surface defects

- High production speeds

Applications:

- Pneumatic tools

- Painting booths

- Leak testing

- Pneumatic valve control

- Component assembly

Textile Industry

Applications:

- Pneumatic weaving looms

- Spinning machines

- Fiber transportation

- Fabric formation

Medical Equipment and Laboratories

Critical Requirements:

- Air sterility

- Supply reliability

- Medical standards compliance

Applications:

- Dental equipment

- Surgical instruments

- Laboratory analyzers

- Ventilators (backup supply)

Economic Efficiency: TCO Analysis

Total Cost of Ownership

When selecting compressor equipment, it is important to consider not only the initial purchase cost, but also total life cycle costs.

Life Cycle Cost Structure

Initial Investment: 10-15%

- Compressor cost

- Installation and commissioning

- Auxiliary equipment

Energy: 75-80%

- Electricity over 10-15 years of operation

- The largest cost item!

Maintenance: 10-15%

- Scheduled maintenance

- Spare parts

- Consumables

- Repairs

EnviroAire TCO Advantages

Energy Efficiency:

- 14% lower energy consumption = 14% savings on the largest cost item

- TVS models: additional savings up to 35%

- Heat recovery: return of up to 94% of energy

Reliability:

- Fewer unplanned downtimes

- Reduced emergency repair costs

- Longer component service life

Ease of Maintenance:

- Faster service = lower technician labor costs

- Longer intervals between maintenance

- Component availability

Product Protection:

- No defects due to air contamination

- Brand reputation preservation

- Avoidance of losses from batch rejection

TCO Calculation Example (15 years)

132 kW compressor, 6000 hrs/year, tariff 0.10 €/kWh

Standard Compressor:

- Initial cost: 50,000 €

- Energy (15 years): 1,188,000 € (132 kW × 6000 hrs × 15 years × 0.10 €)

- Maintenance: 75,000 €

- Total: 1,313,000 €

EnviroAire TVS:

- Initial cost: 75,000 € (+50%)

- Energy (-35%): 772,200 € (savings 415,800 €)

- Heat Recovery: -135,000 € (savings over 15 years)

- Maintenance: 65,000 € (lower due to reliability)

- Total: 777,200 €

Savings: 535,800 € (41%!)

Environmental Benefits

Carbon Footprint Reduction

Lower energy consumption = Lower CO₂ emissions:

- 14-35% energy savings

- Reduction of emissions by tons of CO₂ annually

- Contribution to climate goals achievement

Heat Recovery

- Replacement of fossil fuels for heating

- Reduction of primary energy consumption

- Increased overall enterprise energy efficiency

Durability and Reliability

- Longer service life = less waste

- Fewer replaceable components

- Possibility of upgrade and modernization

Responsible Condensate Management

- Oil/water separators prevent pollution

- Environmentally safe disposal

- Compliance with environmental protection standards

Certifications and Standards

ISO 8573-1:2010 Class 0

Official TÜV certification confirms compliance with the highest class of compressed air quality.

EU Directives

- Machinery Directive

- Low Voltage Directive (LVD)

- Electromagnetic Compatibility Directive (EMC)

- CE marking

Energy Efficiency

- IE5 motors according to IEC 60034-30-2

- Drive system IES2 according to EN61800-9

- Compliance with EU energy efficiency regulations

Industry Standards

- GMP (Good Manufacturing Practice) for pharmaceuticals

- HACCP for food industry

- FDA CFR Title 21 Part 11 (electronic records)

Gardner Denver Support and Service

Global Service Network

Presence in over 100 countries:

- Local support and service

- Fast spare parts delivery

- On-site technical expertise

Personnel Training

- Operator training programs

- Technical personnel training

- Service personnel certification

Technical Documentation

- Complete technical manuals

- Operation and maintenance instructions

- Diagrams and drawings

- Multi-language support

Support Hotlines

- 24/7 technical support

- Expert diagnostics

- Quick response in critical situations

Conclusion: Investment in the Future

Choosing compressor equipment is a strategic decision that affects product quality, operating costs, and enterprise competitiveness for 10-15 years of operation.

2-stage oil-free screw compressors Gardner Denver EnviroAire T/TVS 90-160 represent the most advanced solution, combining:

✓ Guaranteed air quality (ISO 8573 Class 0, TÜV certification)

✓ Maximum energy efficiency (14% better than standard, TVS models up to 35% savings)

✓ Advanced technologies (UltraCoat™, IE5 motors, 2-stage design)

✓ Intelligent control (iConn, Governor 10, Connect 12 Plus)

✓ Reliability and durability (sealed drive system, operation at +46°C)

✓ Comprehensive service (PureCare, genuine parts, global support)

✓ Profitable additional options (heat recovery with payback <1 year)

✓ Environmental responsibility (CO₂ emissions reduction, efficient resource use)

Investment in EnviroAire T/TVS is not just purchasing a compressor, but choosing a partner in ensuring product quality, cost optimization, and sustainable development of your enterprise.

Main attributes 2-stage oil-free screw air compressor Gardner Denver EnviroAire T132 A350028022

Reviews about 2-stage oil-free screw air compressor Gardner Denver EnviroAire T132 A350028022

There are no reviews for this product.

Questions and Answers (FAQ) 2-stage oil-free screw air compressor Gardner Denver EnviroAire T132 A350028022