Application of Screw Compressors

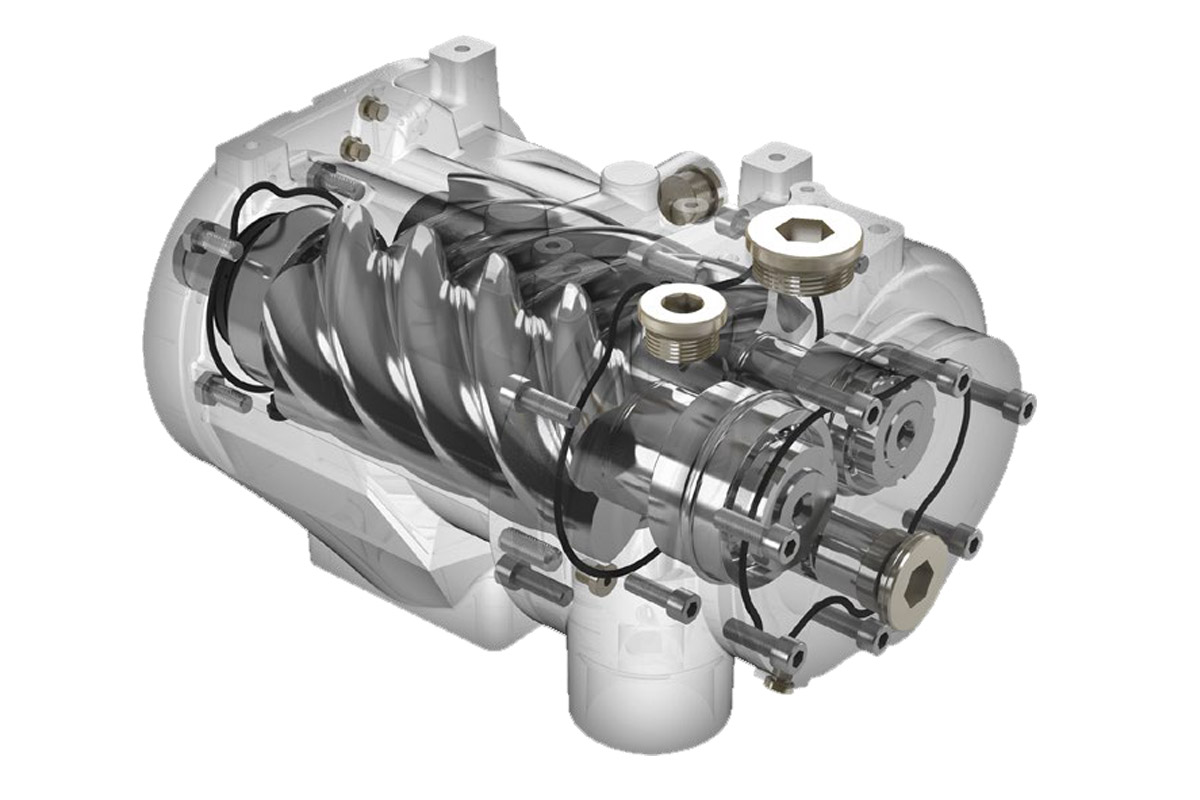

Due to the simple and reliable design, screw air compressors are currently the most popular technology for compressing compressed air in the air lines of industrial enterprises.

Since the early 1960s, with the use of asymmetric rotor profiles, the efficiency and efficiency of screw compressors has increased significantly - this has provided an incentive for industrial enterprises to invest in the replacement of obsolete reciprocating compressor units with more modern - screw. As a rotary unit of volumetric compression, screw air compressors have the following advantages:

- high reliability and resource due to the lack of components with a reciprocating cycle;

- compactness and quietness of a design in combination with supply of high-quality compressed air of constant pressure;

- built-in cooling systems and the ability to work even in hot climates with temperatures up to + 55C;

- Gardner Denver with a history of more than 150 years in the production of compressor equipment -is one of the world's largest manufacturers of compressors in the industrial holding Ingersoll Rand.

- Screw compressors under the Gardner Denver brand - are made at factory in Germany of Zimmern. The plant in Zimmern is a full-cycle plant from design development and production of screw compressor heads to a full cycle of assembly and testing of industrial screw compressors with a capacity of up to 500 kW.

Advantages of screw compressors under the Gardner Denver brand:

- special design of screw blocks with a high resource for difficult operating conditions;

- energy efficient design with a wide range of options for reuse of consumed electricity. energy (heat recovery);

- availability of technologies, both 1-stage compression using oil in the compression chamber, and 2-stage "dry" compression technology "oil free" - without the use of oil in the compression chamber;

- the lowest cost of total ownership of the equipment, due to the use of components and spare parts with an extended service interval of up to 6000-8000 g;

- extended warranty PROTECT 10 - with full warranty service for 10 years for the screw compression unit and 6 years for all components of the compressor station, including electrical equipment and auxiliary units (air preparation, filters, condensate cleaning systems);

- iConn cloud service to warn of emergency shutdowns.

Thanks to a wide network of service centers in Ukraine and Moldova and the availability of components and spare parts in the warehouse of the official importer in Ukraine, Compressors International LLC compressor equipment under the Gardner Denver brand is a benchmark in all industries of Ukraine for over 20 years.