Description Lubricated Rotary Screw Compressor CompAir L110 A34905407

CompAir's L-Series compressors are known for their quality and reliability, making them indispensable in industrial processes. The company is constantly improving the series, achieving high performance and energy efficiency. The models cover the range from L23-L29 (0.92-5.52 m³/min) to L160-L290 (up to 47 m³/min), suitable for construction, processing and mining industries. The optional heat recovery system saves up to 80% energy by using the heat for heating or water heating up to 70°C.

Equipped with IE3 motors (with IE4 option), the compressors provide stable operation with low energy consumption. For example, the L55-L75 deliver 2.20-14.72 m3/min at 5-13 bar, while the L160-L290 deliver up to 12% more air. The Delcos XL touchscreen controller simplifies operation, while iConn alerts you to problems, minimizing downtime. The diesel models meet EU Stage V standards thanks to the Deutz TCD4.1 L4 engine and TurboScrew technology, which saves up to 10% fuel. The 3,500 kg weight makes it easy to transport.

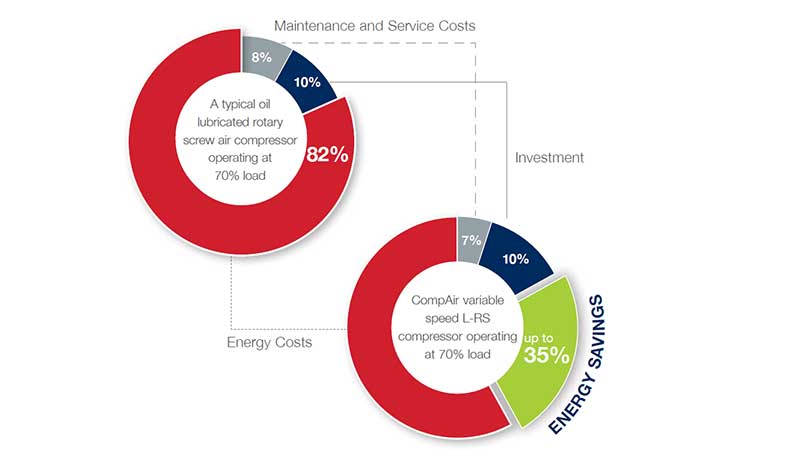

The variable speed (RS) models save up to 25% energy, and the integrated dryer and filtration ensure air with an oil content of less than 3 ppm. ISO 9001:2015 certification and production in Zimmern, Germany, guarantee quality. The compact design and easy access to service points reduce maintenance costs, making the L-Series a worthwhile investment.

Engineering excellence

The L-Series compressors are the key element for a stable supply of quality compressed air at low costs. The screw compression element, manufactured at the CompAir plant in Zimmern using CNC grinding and laser technology, ensures precision and durability. This reduces operating costs and increases productivity.

In-house element production allows for quality control using rotors with nanometer precision. Fixed and variable speed (RS) models adapt to your needs: RS saves up to 25% energy, while fixed speed is suitable for constant loads. For example, the L30-L45 provide a flow of 1.33-8.67 m³/min. Semi-integrated design with oil filter and valve reduces leakage and simplifies maintenance.

IE3 motors (with IE4 option) and a cooling system for operation at 45°C ensure reliability. Heat recovery uses up to 97% of the energy for heating. The Delcos XL system with touch display supports precise control, including error log and remote control. Low noise and vibration levels allow the compressors to be used in the workplace, and their versatility is suitable for workshops and large production.

Premium efficiency of the compression element

The highly efficient L-Series compression element provides quality air at low rotational speeds, reducing energy consumption. Manufactured in Zimmern with CNC grinding and laser technology, it guarantees precision. Semi-integrated design with oil filter and valve minimizes leakage and simplifies maintenance.

The L90-L132 models provide 5.3-24.5 m3/min flow with best efficiency. Separation ensures clean air (<3 ppm oil), ideal for pharmaceutical and food industries. The cooler and fan reduce temperature, extending service life. A 10-year or 44,000-hour warranty emphasizes reliability. RS models save up to 35% energy, and heat recovery reduces costs. The compact design (L55-L75 — 2.23 m2) makes installation easy.

Exceptional reliability and performance

The L-Series stands out for its reliability and performance thanks to screw elements with a 10-year warranty (44,000 hours). RS models save up to 25% energy, and fixed speed is suitable for stable loads. Delcos XL and iConn provide monitoring and protection against downtime. Diesel models comply with EU Stage V, saving up to 10% fuel. Heat recovery uses up to 80% of energy, and the compact design and easy maintenance reduce costs.

Innovative oil control valve

The innovative valve, developed by CompAir, eliminates condensate, preventing corrosion and extending oil life. For RS and Premium Efficiency (e) models, it increases efficiency by up to 5% at low speeds. The integrated design reduces leakage and simplifies maintenance, ensuring reliability for sensitive applications.

Large surface cooler

The cooler ensures low operating temperatures at 45°C, extending service life. The thermostatic fan reduces energy consumption and heat recovery uses up to 97% of the energy. The compact design makes maintenance easy, ideal for construction and recycling.

High-performance separator filter

A two-stage filter ensures clean air (<3 ppm oil) for pharmaceuticalstics and food industries. Hinged cover simplifies maintenance, reducing downtime. Models L55-L75 maintain air quality at pressures of 5-13 bar.

High-efficiency electric motor

IE3 motors (with IE4 option) reduce energy consumption. Automatic bearing lubrication extends their maintenance-free life. RS models save up to 25% energy, optimizing performance.

Best quality connections

Durable hoses and Viton Victaulic connections minimize leaks and simplify maintenance. Reliability ensures stable operation for compact and large installations.

Innovative Delcos XL Touch Controller

The Delcos XL controller with its high-resolution touchscreen is a key feature of CompAir L-Series compressors, providing exceptional convenience and reliability. This control system is designed to simplify the operator's work and protect investments by constantly monitoring operating parameters, reducing operating costs. An intuitive interface with five main menus makes all functions easily accessible, and multilingual support ensures convenience for users around the world.

Homepage displays an instant overview of the compressor's status, including pressure, temperature and operating status, allowing operators to quickly assess performance. Real-time clock allows you to pre-set compressor on and off times, optimizing operation according to production schedules. The Secondary Pressure Setting function allows the compressor to adapt to different conditions, for example by reducing the pressure during periods of low demand to save energy.

Integrated cooling and dryer control ensures that all components operate in sync, maintaining compressed air quality with an oil content of less than 3 ppm, which is critical for industries such as pharmaceuticals or the food industry. The Fault History Log stores detailed information on any faults, facilitating analysis and preventing recurring problems. Remote control via programmable inputs allows the compressor to be integrated into automated systems, while automatic restart after a power failure minimizes downtime.

The Base Load Sequencing option allows the operation of multiple compressors to be coordinated, optimizing their performance and reducing energy consumption. The SDcard stores performance data such as pressure, motor speed and flow rate, making it easy to diagnose and plan maintenance. Integration with iConn provides remote monitoring and real-time notification of potential problems, increasing reliability and reducing the risk of accidents.

Delcos XL supports L-Series models, from the compact L23-L29 (0.92-5.52 m³/min) to the powerful L160-L290 (up to 47 m³/min), providing precise control for a variety of applications, from construction to recycling. The system helps save up to 25% energy in variable speed (RS) models by adapting to changing demand. For example, the L55-L75 models (2.20-14.72 m3/min) optimize performance through precise parameter adjustment via Delcos XL.

The high-resolution touch screen provides clear data display, simplifying operation even in difficult conditions, such as temperatures up to 45°C. ISO 9001:2015 certification and production in Zimmern, Germany, guarantee the quality of the controller, which can withstand intensive use. Delcos XL is not only convenient, but also economical due to the optimization of the compressor operation.

Trend Charts

The trend chart feature in Delcos XL allows for detailed analysis of compressor performance through graphical representations, helping to fine-tune parameters for maximum efficiency. This feature displays key metrics such as line/network pressure, engine speed (for RS models), load hours/total hours, flow rate and weekly average flow rate, giving a complete picture of system performance.

Line/network pressure reflects the stability of the air supply, allowing operators to quickly identify deviations and adjust settings. For RS models such as L90-L132 (5.3-24.5 m3/min), the motor speed diagram shows how the compressor adapts to changing demand, saving up to 35% energy. Load hours/total hours helps to assess the efficiencycompressor efficiency, which is important for maintenance planning.

Flow volume and Weekly average flow volume allow for real-time performance analysis and compressed air demand forecasting, which is particularly useful for large productions. For example, the L160-L290 models can optimize flow up to 47 m3/min with precise settings via charts. Data is stored on an SD card, making analysis and reporting easier.

Trend charts integrate with iConn, allowing for remote viewing of metrics and alerts on deviations, reducing the risk of downtime. This feature makes the L-Series ideal for automated systems where precision and efficiency are key.

CompAir L160-L250 RS Variable Speed Models

The CompAir L160-L250 RS (Regulated Speed) compressors (160-250 kW) are a highly efficient solution for industrial applications with variable compressed air demand. These models provide pressures from 5 to 13 bar and air flows from 6 to 47 m³/min, making them versatile for various production needs, such as the automotive, food or textile industries. The main advantage of RS technology is the automatic adjustment of the motor speed depending on the current compressed air demand. This allows for significant energy savings compared to fixed-speed compressors, which often run idle, wasting energy.

RS models feature the Delcos XL intelligent controller with iConn, which provides real-time monitoring of parameters such as pressure, temperature and capacity. This allows for optimized compressor operation, reducing operating costs and preventing potential failures. Variable speed technology is particularly effective in conditions of uneven air consumption, where the compressor reduces speed when demand decreases, reducing energy consumption by up to 30% compared to traditional systems. A stable air supply with minimal pressure fluctuations improves the quality of pneumatic equipment, which is critical for precise manufacturing processes. Energy savings contribute to reduced CO2 emissions, meeting modern environmental standards. RS models L160-L250 – it is the optimal choice for companies that seek energy efficiency, flexibility and reliability in operation.

Heat recovery in CompAir L-Series compressors

Heat recovery in CompAir L-Series compressors is an advanced technology that allows you to convert waste energy into a valuable resource, significantly reducing operating costs and increasing energy efficiency. During the air compression process in rotary screw compressors, up to 70% of the energy consumed is converted into heat, which is usually lost through cooling systems such as fans or water circuits. These systems not only waste additional energy to remove heat, but also lose a potentially useful resource. The CompAir heat recovery system captures this heat (temperature 70-90°C) and directs it to useful purposes, such as water heating, space heating, steam generation or material drying, which reduces the need for additional energy resources.

The recovery system can be installed at the factory or added to existing compressors as a retrofit. It includes all the necessary components - piping, fittings and controls - to use the heat efficiently. For example, a 160 kW compressor can recover up to 112 kW of thermal energy, which can cover a significant part of the company's hot water or heating needs. In industrial processes, such as cleaning, washing or material processing, hot water is indispensable, and in the cold season the recovered heat is effectively used to heat workshops or warehouses. In the woodworking, textile or food industries, heat is used to dry products, which reduces the cost of specialized equipment.

The economic benefits of heat recovery are impressive. For example, Just Trays achieved annual savings of £23,000 after implementing the system, and otherwise reducing natural gas consumption by 15% brought €8,000 savings every year. The payback period of the system is usually 1-3 years, depending on operating conditions and energy costs. After this period, the savings become a net profit. Environmental benefits include a significant reduction in CO2 emissions, as recovery replaces traditional heating methods such as gas combustion or electrical heating, contributing to sustainability and compliance with environmental standards.

The recovery system integrates with the Delcos XL controller, which provides real-time monitoring and optimization of heat use. The combination with building management systems (BMS) allows automatic coordination of the heat recovery operation with other heating or ventilation systems. The combination with the RS model is particularly effective.we are variable speed, where a stable temperature increases the recovery performance. IoT technologies open up prospects for intelligent control, allowing you to predict heat demand and optimize system operation. CompAir L-Series heat recovery – is not only a technological solution, but also a strategic investment in energy-efficient, cost-effective and environmentally responsible production.

CompAir Compressor Service: Guarantee of Efficiency and Reliability

CompAir compressor service is critical to ensure their reliable, efficient and safe operation. The use of original CompAir Genuine Parts guarantees optimal system performance, reduced energy consumption and minimized downtime risks. Regular maintenance in accordance with the recommended intervals avoids pressure losses due to poor-quality filters, which can significantly increase energy consumption. Such costs often exceed the cost of timely service. The use of non-original components, even if they are similar in appearance, can lead to reduced performance, increased wear or even accidents, which threatens production safety.

CompAir offers specialized service kits that include all the necessary original spare parts and wear parts for specific compressor models. Below is a table with examples of service kits and oils for models L160 - L290:

|

Model |

Kit number |

Description |

|

L160 - L290 |

CK4GD10-1-N |

Separator Kit (requires CK2 Kit) |

|

L160 - L290, RS -A/-W |

CK4GD10-2-N |

Separator Kit (CK2 Kit required) |

|

L160e - L290e |

CK4GD10DS-1 |

4000 Hour Service Kit |

|

L160e - L290e, RS -A/-W |

CK4GD10DS-2 |

4000 Hour Service Kit |

|

L160e - L290e, RS -W |

CK4GD10DS-3 |

4000 Hour Service Kit |

|

L160 - L290, RS -W |

CK4GD10-3-N |

Separator Kit (CK2 Kit required) |

|

L160 - L290 -A, RS |

CK8GD10-1-N |

Major Kit (requires CK4 Kit) |

|

L160 - L290 -W, RS |

CK8GD10-2-N |

Major Kit (requires CK4 Kit) |

|

L160 - L250 |

SCWOBG2-5 |

Screw Warranty Oil Fluid Force, 5 l |

|

L160 - L250 |

SCWOBG2-20 |

Screw Warranty Oil Fluid Force, 20 l |

|

L160 - L250 |

A92130520 |

CompAir Warranty Oil AEON S, 5 l |

|

L160 - L250 |

A92130530 |

CompAir Screw Warranty Oil AEON S, 20 l |

These kits provide complete maintenance, including replacement of filters, separators and other wearing parts. Original oils, such as Screw Warranty Oil Fluid Force and CompAir Warranty Oil AEON S, are designed specifically for CompAir compressors, which guarantees their durability and stable operation. For example, AEON S oil provides optimal lubrication, reducing friction and wear of components.

Using original components allows you to maintain energy efficiency, avoid expensive repairs and extend the service life of the equipment. CompAir emphasizes that only certified spare parts meet quality standards, while non-original counterparts can lead to serious problems, including loss of warranty. Regular maintenance using service kits and oils ensures uninterrupted operation of compressors, reduces operating costs and increases production safety.

For more information about service or ordering spare parts, contact official CompAir representatives. Timely service - this is the key to the efficient operation of your equipment.

Main attributes Lubricated Rotary Screw Compressor CompAir L110 A34905407

Reviews about Lubricated Rotary Screw Compressor CompAir L110 A34905407

There are no reviews for this product.

Questions and Answers (FAQ) Lubricated Rotary Screw Compressor CompAir L110 A34905407