Description Lubricated Rotary Screw Compressor CompAir L55e A349057025

CompAir L55 — is a premium industrial screw compressor designed for stable and economical operation in the most demanding conditions. With its innovative design and premium components, the L55 delivers powerful performance, reduced energy consumption and long service life.

Key benefits of the new generation

High-efficiency semi-integrated screw units GD6 and GD8

The latest optimized screw units deliver increased performance, greater efficiency and reduced pressure drop.

- Maximum efficiency: up to 7% better than previous models.

- Compactness: takes up an average of 8% less space than similar competitor products.

- Automatic oil control valve: implemented in variable speed models, further improving efficiency.

- Automatic lubrication system motor: extends bearing life and requires no maintenance.

Easy to maintain and operate

- New slim separator with integrated seal: simplifies maintenance as it does not require replacing O-rings.

- Removable hinged door: provides easy access to all components and saves space.

- Premium electric motor: compressors are equipped with high-efficiency electric motors, which ensures stable performance and low operating costs.

Key model updates:

- New GD6 unit with 5-6% higher efficiency at high speeds

- Overall efficiency improvement on 3-8%

- 11% smaller than previous models

- New automatic oil control system for variable speed models

- Integrated single-seal separator for easy maintenance

- All-metal, weld-free housing with hinged doors for easy access from any point

CompAir's L Series — synonymous with quality and reliability

CompAir has continuously improved the L Series, achieving the highest levels of efficiency and performance. The range of oil-filled screw compressors from 55 to 75 kW includes fixed and variable speed models, as well as the best-in-class efficiency E Series models. Models with integrated heat recovery and additional dryer are available upon request.

Engineering excellence for your business

CompAir screw compressors are more than a financial investment. They guarantee the stable operation of enterprises, providing a constant supply of high-quality air at minimal costs.

The screw compressor unit is the heart of the device. CompAir carries out its own development and production, using modern CNC machines for grinding rotors and online laser technologies. The result is high reliability, efficiency and low operating costs throughout the entire life of the equipment.

Premium GD6 Screw Unit

The new GD6 screw unit provides up to 5% efficiency improvement over the previous model, reduces pressure drop and has an optimized compact design. The unique design with integrated oil filter and oil control valve reduces the number of external hoses to a minimum, ensuring high reliability, trouble-free operation and easy maintenance. The screw units are covered by a free Assure warranty — up to 44,000 hours or 10 years*.

* whichever comes first.

Technical specifications:

- Pressure range: 5-13 bar

- Flow rate: 2.1-14.8 m³/min

- Motor power: 55 kW

- Cooling options: air and water

CompAir L-Series: Savings with variable speed models and heat recovery

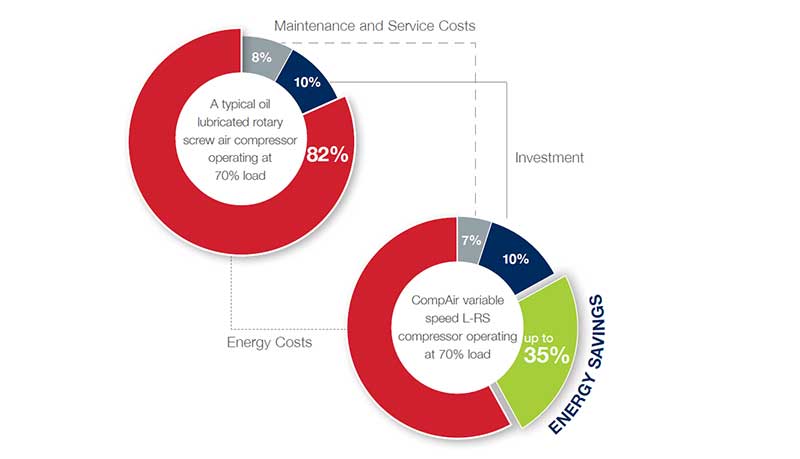

Savings with variable speed models

Variable Speed Drive (VSD) or Regulated Speed (RS) technology represents one of the most significant innovations in the compressed air industry. air of recent decades. The CompAir L-Series with RS technology demonstrates a revolutionary approach to optimizing energy consumption in industrial compressor systems, providing savings of up to 35% compared to traditional fixed speed compressors.

How variable speed technology works

The basis of RS technology is the automatic adjustment of the speed of the compressor motor according to the current demand for compressed air. Unlike traditional fixed-speed compressors that operate in the "load-unload" mode, RS compressors smoothly adapt to changes in air consumption in real time.

The technology works on the principle of frequency control, where a frequency converter (variable frequency drive) changes the frequency of the electric motor supply, which directly affects the speed of the compressor rotor. This allows you to precisely control the compressor performance according to the instantaneous demand for compressed air.

The control system constantly monitors the pressure in the compressed air network and automatically adjusts the compressor speed to maintain the set pressure. When the demand for air decreases, the compressor automatically reduces the speed, and when the demand increases, it increases it. This process occurs smoothly and continuously, ensuring a stable pressure in the system without significant fluctuations.

Economic advantages of RS-technology

The most obvious advantage of variable speed technology is the significant energy savings. CompAir L-RS compressors can provide energy savings of up to 35% compared to traditional fixed speed compressors. This savings is achieved because RS compressors consume only the amount of energy necessary to meet the current demand for compressed air.

In a typical industrial application, a fixed speed compressor operating at 70% load consumes 82% of full capacity, while a CompAir L-RS compressor at the same load consumes only 70% of capacity. This represents a direct energy saving of 12%, which can translate into thousands of euros per year for a typical industrial plant.

The CompAir L-Series e-models demonstrate even more impressive energy efficiency figures. Thanks to the integrated automatic oil control valve and other technological improvements, these models are able to provide savings of up to 6.8% compared to standard models. Calculations show that the e-models can save up to 4,500 euros per year in electricity costs alone.

Technological innovations in the RS models

The key innovation in the CompAir L-Series RS models is the integrated automatic oil control valve. This valve was specially developed by the CompAir engineering team and offers several important advantages. Firstly, it eliminates the risk of condensation, which prevents corrosion and extends the life of the oil. Secondly, depending on operating conditions, the valve can improve efficiency by 5% for variable speed models. Thirdly, it significantly improves operation at low speeds, which is especially important for optimizing energy consumption at minimum loads.

The new automatic motor lubrication system, which is included as standard, not only extends bearing life, but also requires no maintenance. This reduces operating costs and increases compressor reliability.

The Delcos XL SE7 controller with a 7-inch high-resolution touch screen provides intuitive control of RS functions. The system allows for fine-tuning of operating parameters, including motor speed, network pressure, trend monitoring and efficiency analysis. This gives operators the opportunity to maximize energy savings and optimize system operation.

Adaptability to variable demand

One of the greatest advantages of RS technology is its ability to effectively handle the variable demand for compressed air, which is typical of most industrial applications. Traditional fixed-speed compressors operate inefficiently at part load, while RS compressors demonstrate high efficiency over a wide range of loads.

Many industrial enterprises have variable demand for compressed air throughout the day, week or season. For example, in production workshops, demand can decrease significantly during breaks, shifts or weekends. RS compressors automatically adapt to these changes, reducing rotation speed and, accordingly, energy consumption during periods of low demand.

This adaptability is especially valuable for enterprises with seasonal production fluctuations. For example, food processing plants may experience increased demand for compressed air during canning season or holiday periods. RS compressors can save significant energy costs during periods of low demand, while still maintaining the ability to deliver the required performance during peak times.

Impact on howcompressed air quality

RS technology not only saves energy, but also improves the quality of compressed air. Smooth speed control allows you to maintain a more stable pressure in the network, which is especially important for sensitive industrial processes. Less pressure fluctuations mean better end product quality and fewer scrap.

Stable pressure also contributes to more efficient operation of pneumatic equipment. Tools and machines that operate on compressed air demonstrate better performance and accuracy when the supply pressure is stable. This can lead to an increase in the overall efficiency of the production process.

Reduced mechanical wear

The smooth operation of RS compressors significantly reduces mechanical wear compared to fixed speed compressors that constantly switch between load and unload modes. Less wear means longer equipment life, reduced maintenance and repair costs.

Of particular importance is that RS technology reduces the number of engine starts. Each engine start places a significant load on electrical and mechanical components, leading to accelerated wear. RS compressors run smoother, with fewer starts, which extends the life of all system components.

Economic efficiency throughout the life cycle

A Total Cost of Ownership (TCO) analysis shows that CompAir L-Series RS compressors demonstrate significant advantages over the entire life cycle. Although the initial cost of RS compressors may be slightly higher than fixed speed compressors, the energy savings and reduced maintenance costs quickly compensate for this difference.

Energy costs account for the largest share of a compressor’s operating costs over its life cycle. A typical compressor can consume 5-10 times more energy than its initial cost. Therefore, even relatively small energy savings can lead to significant monetary savings over the life cycle of the equipment.

Environmental benefits

RS technology also provides significant environmental benefits. Reducing energy consumption is directly proportional to reducing CO2 and other greenhouse gas emissions. For companies striving to achieve their sustainability goals, RS compressors represent an effective way to reduce their environmental footprint.

In addition to reducing emissions, RS technology also contributes to a more rational use of energy resources. This is especially important in the context of rising energy prices and stricter environmental regulations in many countries.

Heat recovery

Heat recovery is one of the most effective and undervalued technologies for reducing energy consumption and operating costs of compressor systems. The CompAir L-Series offers an integrated heat recovery system that converts waste energy into useful heat for a variety of industrial and commercial applications.

Physical Basis of Heat Recovery

The process of compressing air in rotary screw compressors is accompanied by the release of significant heat. This heat is generated as a result of the thermodynamic compression process, where mechanical energy is converted to heat. Approximately 70% of the energy consumed by a rotary screw compressor is converted to heat during the compression process.

In traditional compressor systems, this heat is considered an unwanted by-product that must be removed through cooling systems. Cooling fans or water cooling systems use additional energy to remove this heat to the atmosphere, which represents a double energy loss: first the energy is used to generate the heat, and then the additional energy is used to remove it.

The CompAir heat recovery system allows this heat to be captured and used for useful purposes, such as water heating, space heating, pre-heating water for steam generation or other industrial processes. This turns "waste" energy into a valuable resource, significantly increasing the overall energy efficiency of the system.

Heat Recovery System Specifications

The CompAir integrated heat recovery system can be installed either at the factory or as a retrofit to existing compressors. The system includes all the necessary piping, fittings and control components for efficient heat removal and use.

The system is capable of recovering up to 70% of the energy consumed by the compressor as useful heat. For a 55 kW compressor, this means the possibility of obtaining approximately 38 kW of thermal energy, and for a 75 kW model - about 52 kW. This amount of heat can cover a significant part of the company's hot water or heating needs.

The temperature of the recovered heat is usually 70-90°C, making it suitable for a wide range of applications. This temperature is sufficient for most industrial processes, including water heating, space heating, drying and material pre-treatment.

Applications of recovered heat

CompAir heat recovery opens up a wide range of applications. One of the most common applications is heating water for industrial processes. Many manufacturing plants require significant amounts of hot water for cleaning, rinsing, material handling and other processes. Heat recovery can cover a significant part of these needs, reducing the costs of traditional heating systems.

Space heating is another important application of recovered heat. This works particularly effectively in industrial buildings, where compressors are usually located in compressor rooms or technical rooms. Heat recovery can provide comfortable temperatures in work areas, reducing the cost of traditional heating.

The system can also be used to preheat water for steam generation. Many industrial processes require steam for various purposes, and preheating the feed water can significantly reduce fuel costs for steam boilers.

Drying materials and products is another promising application. Heat recovery can provide the necessary temperature for drying processes, especially in the woodworking, textile and food industries.

Economic benefits of heat recovery

The economic effectiveness of heat recovery depends on several factors, including the type of application, the cost of alternative energy sources and local energy tariffs. In most cases, heat recovery provides significant savings over the course of a year.

A case study from Just Trays demonstrates impressive results. After installing a new CompAir compressor with heat recovery, the company achieved annual savings of £23,000. These savings provided a rapid return on investment and a significant improvement in operating performance.

In another example, the heat recovery system reduced annual natural gas consumption by 15%, resulting in savings of approximately €8,000 per year. These figures demonstrate the real potential of heat recovery to reduce operating costs.

The payback period for heat recovery systems is typically 1-3 years, depending on the specific operating conditions and the cost of alternative energy sources. After the payback period, all savings represent a net profit for the company.

Environmental benefits of heat recovery

Heat recovery provides significant environmental benefits, contributing to the reduction of CO2 and other greenhouse gas emissions. Using recovered heat instead of traditional heating methods (gas, oil or electric heating) directly reduces primary energy consumption.

Every kW of recovered heat that replaces traditional heating methods prevents the release of a corresponding amount of CO2 into the atmosphere. For a typical compressor with a capacity of 55-75 kW, this can mean a reduction of several tons of CO2 per year.

Heat recovery also contributes to the principles of the circular economy by transforming waste into useful resources. This is in line with current sustainable development trends and helps companies achieve their environmental goals.

Technical aspects of implementation

The implementation of a heat recovery system requires careful planning and design. It is important to correctly calculate the heat load and determine the optimal points of use of the recovered heat. The system must be integrated with the existing heating and water supply systems of the enterprise.

A key aspect is to ensure reliable operation of the heat recovery system under different compressor operating modes. The system must operate effectively both at full compressor load and at partial load, especially for RS models with variable speed.

The control and management of the heat recovery system is integrated with the main controller of the Delcos XL SE7 compressor. This allows operators to monitor the efficiency of heat recovery, track energy savings and optimize system operation.

Combination with other energy-saving technologies

Heat recovery is most effective when combined with other energy-saving technologies, such as RS drive and demand management systems. CompAir L-RS compressors with integrated heat recovery represent a complete solution for maximum energy efficiency.

Combining RS technology with heat recovery allows for a synergistic effect. RS compressors operate more consistently and with lesstemperature fluctuations, which ensures more stable operation of the heat recovery system.

Integration with building management systems (BMS) allows you to automatically coordinate the operation of heat recovery with other heating and ventilation systems. This ensures optimal use of recovered heat and maximum energy savings.

Future prospects for heat recovery

Heat recovery is a technology with great potential for future development. Rising energy prices and stricter environmental standards make heat recovery increasingly attractive for enterprises in various industries.

The development of heat pump technologies and heat storage systems opens up new opportunities for more efficient use of recovered heat. Integration with renewable energy sources can create complex energy systems with extremely high efficiency.

Digital technologies and the Internet of Things (IoT) allow for the creation of intelligent heat recovery systems that automatically optimize their operation based on real operating conditions and heat demand forecasts.

The CompAir L-Series heat recovery is not only a technological solution, but also a strategic investment in the future of energy-efficient and environmentally responsible production.

Delcos XL SE7 - Innovative Touch Compressor Controller

The Delcos XL SE7 control system with a high-resolution 7-inch touch display is the heart of the modern CompAir L-Series industrial compressor. This multilingual controller ensures safe and reliable equipment operation, protecting operators' investments by continuously monitoring critical operating parameters, which is a key factor in reducing the total cost of ownership of a compressed air system.

Intuitive design and functionality

The Delcos XL SE7 features an extremely user-friendly and self-explanatory interface. All functions are logically structured in five main menus and presented visually intuitively, allowing operators to quickly master the system without extensive training. The controller is able to display detailed system analysis in the form of trend charts and graphs, allowing you to fine-tune operating parameters to achieve maximum compressor efficiency.

Advanced controller features:

Home page provides an instant overview of the compressor status with all key indicators displayed in real time.

Trend charts provide detailed visualization of line/network pressure, motor speed (for variable speed models), hours under load, total hours and average volumetric flow, including weekly average volumetric flow.

Real-time clock allows you to pre-set compressor start and stop according to the production schedule.

Second pressure setting provides flexibility in managing different operating modes depending on production needs.

Log fault history stores detailed information about all events for in-depth analysis and prevention.

Remote control via programmable inputs allows you to integrate the compressor into the overall automation system of the enterprise.

Automatic restart after a power failure ensures continuity of operation without operator intervention. SD card stores various operating characteristics for further analysis and optimization.

![]()

iConn - Revolutionary remote monitoring

The iConn system as a standard controller feature keeps you one step ahead, predicting potential problems before they occur, saving valuable time and money. This easy-to-use and easy-to-install system not only shows the current status of your equipment, but also demonstrates how to optimize production and increase energy efficiency.

Key benefits of iConn:

- Proactive real-time monitoring 24/7

- Maintenance based on actual component wear

- Maximum compressor performance reduces energy consumption

- Predictive warnings prevent costly downtime

- Early detection of compressed air component wear

- Optimized maintenance planning

- Dew point monitoring for integrated dryer

- Alarm and alert notification via email

The Delcos XL SE7 controller with iConn technology represents the future of industrial automation, pcombining advanced Industry 4.0 technologies with ease of use and absolute data security.

CompAir Genuine Parts - Guaranteed quality and reliability

In the world of industrial equipment, where every minute of downtime can cost thousands of euros, choosing the right spare parts is a critical decision. CompAir Genuine Parts are not just maintenance components - they are a guarantee of safe, economical and efficient operation of your compressor system for many years.

CompAir Quality Philosophy

CompAir understands that the true value of compressor equipment is revealed not only at the time of purchase, but also throughout its entire life cycle. CompAir Genuine Parts are built to the same quality standards as the original equipment, ensuring perfect compatibility, reliability and performance.

Each genuine part is rigorously tested in CompAir’s laboratories, where engineers use state-of-the-art equipment to verify compliance with all technical specifications. This process ensures that every part that bears the CompAir logo meets the highest standards of quality and reliability.

The Criticality of Maintaining Service Intervals

Maintaining scheduled service intervals is not just a recommendation, but a critical necessity to ensure energy efficiency and long-term operation of your compressor system. Skipping or postponing scheduled maintenance can lead to a cascade of problems that will ultimately cost much more than the cost of timely maintenance.

Dirty or worn filters create increased resistance to airflow, forcing the compressor to work harder. This leads to an increase in energy consumption, which can be 20-30% higher than normal. When the energy costs of improperly maintained filters accumulate over months, their cost can exceed the cost of timely maintenance many times over.

Furthermore, ignoring routine maintenance can lead to serious breakdowns that will require expensive repairs or even replacement of major components. The cost of such repairs can be a significant part of the cost of new equipment, not to mention the losses from production downtime.

The danger of using non-original components

At first glance, non-original spare parts may seem like an attractive alternative due to their lower initial cost. However, the external similarity can hide critical differences in the quality of materials, manufacturing precision and durability.

Non-original filters may have poor-quality filter materials that do not provide the proper level of air or oil purification. This can lead to contamination entering critical compressor components, causing accelerated wear and possible failure.

Non-genuine seals and gaskets may be made of materials that are not resistant to the operating temperatures and pressures of CompAir compressors. This can lead to oil leaks, loss of pressure and, in the worst case, serious damage that could endanger personnel.

The use of non-genuine parts may also void the equipment warranty. CompAir guarantees the proper operation of its compressors only when using original spare parts and following the regular maintenance procedures.

Service kits and oils for CompAir compressors L55–L75, RS

|

Compressor model |

Article |

Description |

|

L55 – L75, RS |

CK2GD6-1 |

Standard filter kit (air/oil) |

|

L55 – L75 |

CK4GD6-1-N |

Separator kit (requires CK2 kit) |

|

L55 – L75, RS |

CK4GD6-1-RS-N |

Separator kit (requires CK2 kit) |

|

L55 – L75 |

CK4GD6-1-EK-N |

4000hr service kit (air/oil filter, separator) |

|

L55 – L75 |

FCK4GD6-1-EKF-N |

4000h service kit (air/oil filter, separator) |

|

L55 – L75, RS |

FCK4GD6-1-RS-EKF-N |

4000h service kit (air/oil filter, separator) |

|

L55 – L75, RS |

CK4GD6-1-RS-EK-N |

4000h service kit (air/oil filter, separator) |

|

L55 – L75, RS |

CK8GD6-1-N |

Extended kit (also requires CK4 + CK2) |

|

L75e |

CK8GD6-2-N |

Extended kit (also requires CK4 + CK2) |

|

L55 – L75 |

SCWOBG2-5 |

Fluid Force oil, 5 l – with warranty for screw compressors |

|

L55 – L75 |

SCWOBG2-20 |

Fluid Force oil, 20 l – with warranty for screw compressors |

|

L55 – L75 |

A92130520 |

CompAir AEON S oil, 5 l – with warranty for screw compressors |

|

L55 – L75 |

A92130530 |

CompAir AEON S oil, 20 l – warranty for screw compressors |

Benefits of CompAir Service Kits

CompAir Service Kits are a comprehensive solution for scheduled maintenance, including all the necessary original parts and wear components for the corresponding type of service. This ensures optimal system operation and greatly simplifies the process of planning and performing maintenance.

Each service kit is carefully assembled by CompAir engineers who know exactly which components need to be replaced for each type of service. This ensures that technicians have all the parts they need to complete the job, avoiding delays and additional costs.

Detailed Overview of Service Kits for L-Series

The Standard Filter Kit (CK2GD6-1) is designed for basic maintenance of air and oil filters. This kit ensures regular replacement of filter elements, which are the compressor's first line of defense against contamination.

Separator Kit (CK4GD6-1-N and CK4GD6-1-RS-N) includes high-quality separators specially designed to effectively separate oil from compressed air. The different versions of the kit are designed for standard and variable speed models, ensuring optimal performance for each type of equipment.

4000 Hour Service Kit is a comprehensive solution for major maintenance, including air and oil filters, as well as separators. The different versions of the kit (CK4GD6-1-EK-N, CK4GD6-1-EKF-N, CK4GD6-1-RS-EKF-N, CK4GD6-1-RS-EK-N) ensure an exact match to the specific compressor model.

Major Kit (CK8GD6-1-N and CK8GD6-2-N) is designed for major maintenance and includes the most critical components to be replaced. This kit is used in conjunction with the CK4 and CK2 kits to provide a complete overhaul of all service components.

CompAir Specialty Lubricants

Main attributes Lubricated Rotary Screw Compressor CompAir L55e A349057025

Reviews about Lubricated Rotary Screw Compressor CompAir L55e A349057025

There are no reviews for this product.

Questions and Answers (FAQ) Lubricated Rotary Screw Compressor CompAir L55e A349057025