Description Oil-free two-stage screw compressor CompAir D37 A A35003801_ CA

CompAir, as a leading provider of innovative compressed air technologies, presents the D37 - D75s and D37RS - D75sRS series – high-efficiency oil-free rotary screw compressors with air and water cooling. These models provide 100% oil-free compressed air, making them an ideal choice for industries where air purity is critical: pharmaceuticals, food industry, electronics, textiles and other sensitive productions. Certified according to ISO 8573-1 Class 0 by TÜV, the D series compressors guarantee complete absence of oil, oil vapors, particles and condensate, exceeding the strictest hygienic requirements.

The quality of compressed air is not just a technical parameter, but a key factor in business success. The presence of contaminants can lead to equipment downtime, product spoilage, batch recalls, damage to brand reputation or even legal liability for harm to consumers. The D series eliminates these risks by offering clean air that protects processes and increases overall efficiency. With a pressure range from 7 to 10 bar, volume flow from 5.1 to 12.7 m³/min and power from 37 to 75 kW, these compressors are adapted for medium and large industrial applications where reliability and economy are needed.

The D series compressors stand out not only for air purity, but also for economic advantages

Lower cost of ownership: Although initial investments are higher than in oil counterparts, they pay off quickly due to the absence of costs for oil, filters and disposal, as well as lower operational and maintenance costs. Over 5 years of operation, energy accounts for up to 80% of total costs, but the D series minimizes them thanks to efficient technologies. Reliability: Robust design with patented Ultracoat™ treatment protects rotors and compression chamber from corrosion, extending service life. Stainless steel on the cold side, efficient inlet filter and IP65 class electrical protection ensure stable operation even in harsh conditions. Productivity: Class 0 oil-free air eliminates the risk of contamination, preventing product spoilage and waste, which increases production efficiency. Serviceability: The design provides easy access to key components without special tools. Coolant replacement interval – 8000 hours, and built-in iConn simplifies monitoring. Assure service programs provide scheduled maintenance with extended warranty. PureAir Technology: When Air Purity Has High Priority PureAir is CompAir's philosophy focused on providing the highest purity of compressed air. The D series meets class 0 according to ISO 8573-1, where the content of oil and oil vapors is less than 0.01 mg/m³ – this is the strictest standard. Compared to other classes (Class 1: 0.01 mg/m³, Class 2: 0.1 mg/m³, Class 3: 1 mg/m³, Class 4: 5 mg/m³), Class 0 excludes any contamination, making the compressors ideal for hygienic processes.

CompAir is a full cycle of support: from needs analysis and consulting to project planning, installation, service, warranty, genuine spare parts and remote monitoring via iConn. This ensures that your compressed air system will operate optimally at all stages.

Key Features The D series combines advanced technologies for maximum performance and efficiency

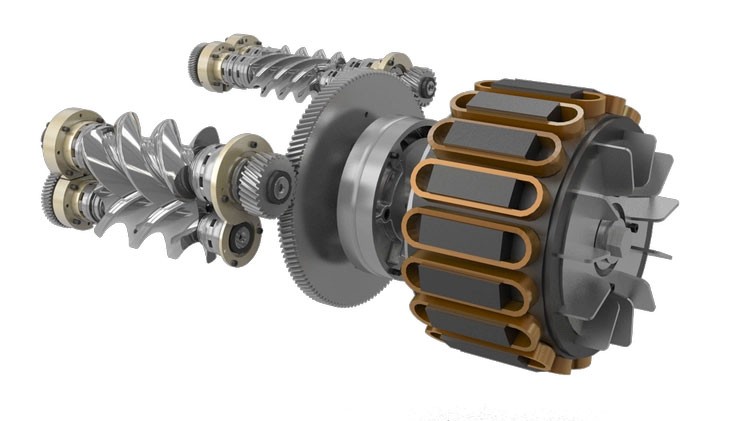

Class 0 oil-free rotary screw compressors: Air/water cooling, fixed (FS) and variable speed (RS). Highest productivity: Clean air for demanding industries, intuitive controller with detailed event log, extended communication and integration with control systems. Optimal efficiency: RS models with hybrid permanent magnets (HPM) exceed the IES2 standard for drives. Hot air discharge option for HOC dryers without additional energy, compatibility with innovative Subfreeze dryers. Energy recovery system (ERS Ready) converts heat into useful energy, saving thousands of euros per year. Maximum reliability: Ultracoat™ for anti-corrosion protection, stainless steel and aluminum on critical elements, efficient inlet air filter. Easy maintenance: Quick access, without special tools, iConn in standard configuration, service programs. Robust Air End Design The heart of the compressor is a two-stage air end with stainless steel rotors, precision gears and oversized bearings. Patented Ultracoat™ – the most durable coating in the industry – protects against corrosion, ensuring longevity. Treated pipes and stainless steel components on the cold side minimize contamination risks. Dual Vented Seals with stainless rings, labyrinth oil seal and venting to atmosphere guarantee 100% oil-free air at any time, preventing contaminant penetration.

Butterfly Inlet Valve with hydraulic actuator and mechanical linkage to the blow-off valve does not require replacement every 8000 hours, unlike diaphragm valves, which increases reliability and reduces costs.

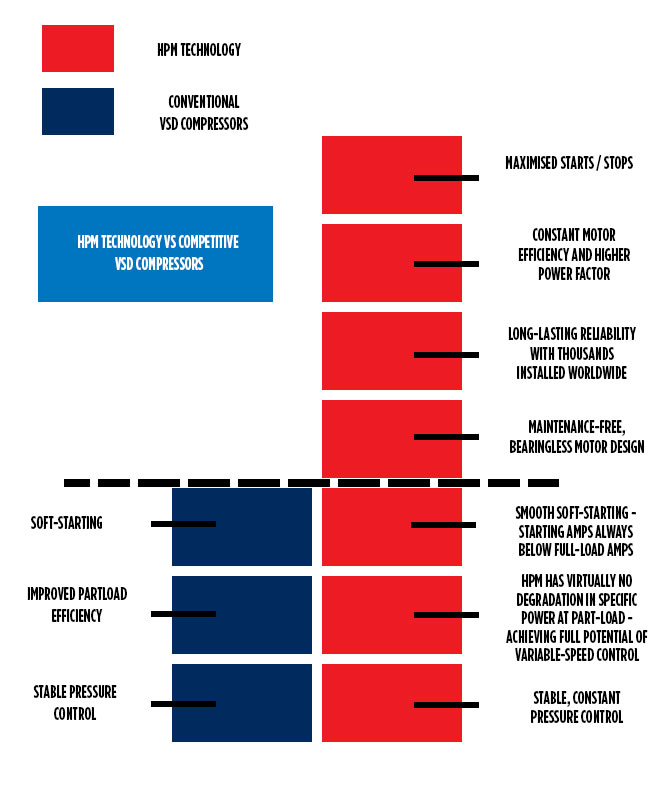

Advantages of HPM Technology (Hybrid Permanent Magnet) in RS Models RS models are equipped with advanced HPM motors that outperform standard VSD (Variable Speed Drive) compressors. HPM provides constant 95% efficiency from start-up to full speed range, without degradation at partial load. This allows producing more air without increasing energy consumption, saving up to 30% energy compared to traditional systems.

Key HPM advantages

Constant efficiency: 95% at start and throughout the range, stable pressure and higher power factor. Unlimited starts/stops: Immediate shutdown when there is no demand, without blow-off or unloading time. Testing confirmed 45,000 cycles in 3000 hours without wear. Soft start: Currents always below full load, extending motor life. Simple design: 60% fewer components than in standard induction motors – no gears, pulleys, bearings, seals or alignment. Precision stator winding eliminates "hot spots", ensuring cool operation. Durability: Thousands of installed systems worldwide, low maintenance costs, increased reliability. Compared to conventional VSD, HPM offers maximized cycles, stable pressure, better efficiency at partial load and no power degradation.

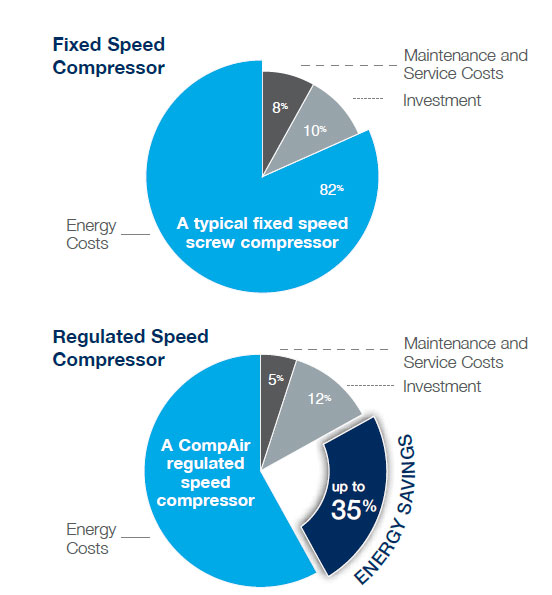

Variable Speed Compressors (RS) D37RS - D75sRS models ideally adapt to variable demand, producing only the required amount of air. This minimizes idling, blow-off losses and energy consumption, reducing total cost of ownership by up to 35% compared to fixed speed. Wide regulation range eliminates cycles, ensuring stable pressure and energy savings – especially useful in industries with variable load, such as food or pharmaceutical.

Saving Energy and Protecting the Environment: Over 5 years, energy accounts for 80% of compressor costs, but RS models precisely follow the load curve, minimizing waste. This not only saves money, but also reduces CO2 emissions, contributing to environmental sustainability. CompAir focuses on green technologies, turning compressors into a tool for environmental protection.

Controller

The intuitive DELCOS controller with a large graphical interface provides full compressor control. Web-like navigation simplifies setup, and a detailed event log records hundreds of parameters: pressure, temperature, load, errors, etc. Integrated variable speed control (for RS) optimizes operation in real time. Extended communication options – Modbus, Profibus, Ethernet – allow integration with SCADA systems or remote access. The controller monitors efficiency, warns of potential problems, optimizes energy consumption and supports multiple languages. This is not just a panel – it's a smart center that increases productivity and reduces risks.

SmartAir Control System SmartAir Master is an intelligent compressed air control system that optimizes the operation of up to 12 compressors (fixed or RS), including downstream equipment. Why is it necessary? Energy is the largest cost factor for a compressor (up to 80%), and systems with multiple compressors often waste it due to uneven load. SmartAir harmonizes operation, narrowing the pressure band to a minimum, equalizing operating hours for economic service and eliminating waste.

Base load Controls up to 4 compressors, matching supply to demand. Advantages: Reduced energy consumption, increased productivity, monitoring optimization, even wear. This is a profitable investment: payback through even hours, reduced downtime and CO2 emissions.

Heat Recovery – Profitable Investment

Compressor thermodynamics converts 94% of energy into heat, which is usually lost to the atmosphere. The D series with Heat Recovery system (ERS Ready) allows recovering this heat for hot water, space heating, industrial processes or pre-heating for steam generation. This saves thousands of euros per year, with payback less than 1 year, reduces cooling costs and CO2 emissions.

Advantages: Significant energy savings, low investments, easy installation without affecting air supply, small ecological footprint, high reliability. Available for all water-cooled models – this is a turnkey solution that turns waste into a resource.

Air and Condensate Treatment AirPlus Modern processes require ideal air purity, so CompAir offers a full AirPlus range: water cyclone separators, compressed air filters, condensate drain systems, refrigeration dryers, heatless and heat regenerative adsorption dryers, HOC dryers, Subfreeze dryers and nitrogen generators. This ensures 100% compliance with standards, protecting equipment and processes from contaminants.

Investment Protection with Assure Assure service agreements with extended warranty prevent unexpected downtime. Advantages: Lower cost of ownership through optimized maintenance, quality results from certified technicians, increased uptime, efficient energy use, peace of mind with warranty up to 10 years. This is a comprehensive approach: audit, inspection, genuine parts – all for maximum efficiency.

iConn: Predictive Maintenance 4.0 Standard in the D series

iConn – a smart real-time monitoring system that analyzes data, predicts problems, optimizes efficiency and reduces downtime. Works as an open standard, evaluates historical data, maximizes energy efficiency, supports remote analysis. Free on new compressors, can be retrofitted – this is Industry 4.0 for your air.

CompAir Genuine Parts Reliability guarantee: genuine parts ensure long service life even in harsh conditions, minimal energy losses, high efficiency. Manufactured to strict standards, they increase uptime and reduce costs.

Main attributes Oil-free two-stage screw compressor CompAir D37 A A35003801_ CA

Reviews about Oil-free two-stage screw compressor CompAir D37 A A35003801_ CA

There are no reviews for this product.

Questions and Answers (FAQ) Oil-free two-stage screw compressor CompAir D37 A A35003801_ CA