Description Oil-free two-stage screw compressor CompAir DX315 W WDX315851

World industry constantly evolves, and quality compressed air plays key role in ensuring uninterrupted operation. Oil-free screw compressors CompAir series DX — this advanced solution, which guarantees 100% clean air without impurities oil. Series DX200-DX355 and models with adjustable speed (RS) — this ideal choice for those, who value reliability, efficiency, and environmental friendliness. These compressors, available with air and water cooling, created for most demanding conditions and meet most stringent hygienic standards.

Why choose series DX?

CompAir — this brand with over 200-year experience in development systems compressed air. We offer not just equipment, but comprehensive solutions, which protect your reputation, reduce risks downtime and ensure high quality final product. Compressors series DX certified by standard ISO 8573-1 Class 0, which confirms absence oil in air at level less 0.01 mg/m³. This ideal for pharmaceutical, food, and other sensitive industries.

World level efficiency - newest modular air blocks with optimized profile rotors provide significant increase efficiency and best in its class air flow. Premium variants with water jackets air block (e-variants) open new horizons energy saving.

Reliable components - Proven time air blocks with patented technology UltraCoat™, reinforced excessively large bearings, robust engines, and coolers, operating at temperatures up to 46°C, as well as hydraulically controlled inlet valves, guarantee durability and reliability for life.

Flexible design solutions - Compressors offer configurations with air and water cooling, fixed and adjustable speed, various options pressure, adaptation to extreme temperatures, high filtration dust, and modifications for external use in harsh conditions — all for ideal selection for your needs.

Simplicity and accessibility maintenance - Design oil-free compressors simple and thoughtful: no special tools required. All components easily accessible, and durable consumables extend intervals maintenance.

Enhanced cooling capacity - Systems designed for operation in conditions temperature up to 46°C, providing additional reserve cooling for uninterrupted operation in hot conditions, which increases overall reliability and efficiency.

Technology PureAir: purity compressed air in first place

Technology PureAir from CompAir ensures air highest quality, corresponding class ISO 8573-1 Class 0. This means complete absence particles, condensate, and oil vapors, which critically important for industries, where purity is priority. Our compressors Old compressors certified TUV, which guarantees compliance highest standards.

Classes quality air by ISO 8573-1

- Class 0: < 0.01 mg/m³

- Class 1: 0.01 mg/m³

- Class 2: 0.1 mg/m³

- Class 3: 1 mg/m³

- Class 4: 5 mg/m³

Innovative design air block

Air block our compressors — this heart technology. Thanks unique coating UltraCoat rotors and housing we achieve exceptional resistance to corrosion and wear. Secondary rotor from stainless steel together with this coating ensures durability, stable performance, and reduction energy consumption. Pressure from 4 to 10 bar and productivity from 11.4 to 53.4 m³/min make series DX universal for any tasks.

Key features air block

- Increased productivity by 8% compared with standard models.

- Energy saving up to 7% (fixed speed) and 5% (variable speed).

- Models with water cooling provide additional efficiency.

Flexibility and efficiency

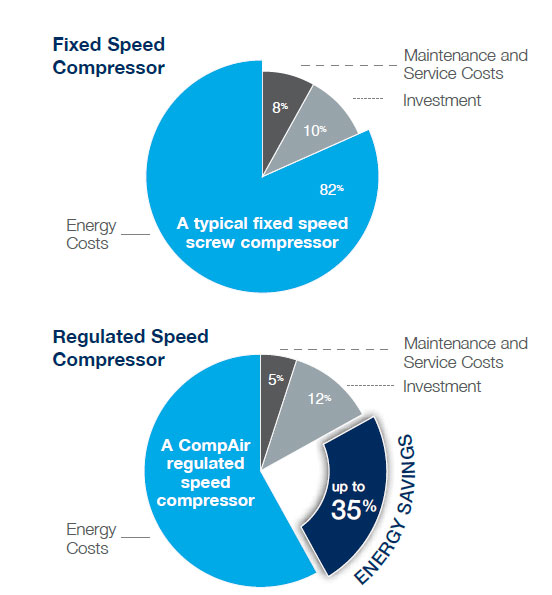

Series DX offers fixed and adjustable speeds (RS), which allows adapt compressor to your needs. Models with adjustable speed provide savings up to 35% energy compared with traditional fixed systems thanks wide range regulation — up to 71%. Integrated drives variable frequency optimize operation, avoiding idle running.

Advantages adjustable speed

- Energy saving due to operation closer to target pressure.

- Absence cycles increases energy efficiency.

- High reliability thanks ideal combination engine, drive, and air block.

Smart management and monitoring

Modern controllers Xe-Series provide intuitive interface and possibility remote access through any browser. Models with adjustable speed can synchronize operation up to four compressors without additional equipment, stabilizing pressure and increasing efficiency.

iConn: smart maintenance

- Predictive maintenance based on historical data.

- Maximization energy efficiency.

- Reduction downtime thanks proactive monitoring.

Heat recovery: ecological solution

About 94% energy, spent on compressor, turns into heat. Our systems allow recover this heat for hot water, heating premises, or preheating for steam generators. This not only saves costs, but also reduces emissions CO₂. Payback period such systems usually less year.

Your benefits from heat recovery

- Significant savings on energy.

- Low investment costs.

- Simplicity installation and operation.

Air processing and condensate management

System AirPlus ensures comprehensive air processing, including cyclone separators, filters, dryers, and nitrogen generators. This guarantees, that your equipment always operates with air highest quality, protecting it from damage.

Products for air processing

- Cyclone separators.

- Compressed air filters.

- Regenerative dryers.

Protection your investment

Investments in service agreements Assure protect your compressor from unforeseen costs. Thanks planned maintenance you get lower cost ownership, higher productivity, and peace, knowing, that your equipment in reliable hands.

Advantages service agreements

- Reduction costs on maintenance.

- Increase service life equipment.

- Guarantee for case unforeseen situations.

Technical support and global service

CompAir offers global expertise with local support. Our network service centers and original spare parts guarantee, that your equipment always in perfect condition. Contact us for professional air audits, leak detection, and individual solutions.

Why choose CompAir?

- More 200 years engineering experience.

- Environmentally friendly and energy-efficient solutions.

- Individual approach to each client.

Learn more about how compressors CompAir series DX can increase your productivity and reduce costs. Contact us for consultation and selection optimal solution for your business!

Main attributes Oil-free two-stage screw compressor CompAir DX315 W WDX315851

Reviews about Oil-free two-stage screw compressor CompAir DX315 W WDX315851

There are no reviews for this product.

Questions and Answers (FAQ) Oil-free two-stage screw compressor CompAir DX315 W WDX315851