Description Refrigeration Dryer Sub Zero CMT266

Energy efficient, sub zero regenerative refrigeration dryer, dew point: -20°C

The Sub Zero (CMT) refrigeration dryers from CompAir are the only refrigerant dryers available on the compressed air market today that provide ISO Class 3 dry air with a dew point of -20°C. These performance levels are made possible by the dryer's unique design. They combine the ease of maintenance and operation of a refrigeration dryer with the dew point performance of adsorption dryers. Sub Zero dryers take clean and dry air to a new level of cost-effectiveness in a wide range of operating conditions.

CMT+ models include a heater kit for low inlet temperature conditions.

Key technical characteristics of the Sub Zero (CMT and CMT+) series:

- Air flow range: 6–27 m³/min.

- Maximum pressure: 14 bar

- Dew point: -20 °C

- Refrigerant: R452A (R449A optional)

- Power supply: 400/3/50

- Drainage: built-in lossless drainage

- Programmable Xe90D controller

- Control system connectivity: Modbus, iConn

The CMT series is an extremely cost-effective alternative to adsorption dryers, which optionally provide the ability to obtain ISO 3 class air. Sub Zero dryers provide the lowest operating costs with deep drying at -20°C.

Advantages of the Sub Zero dryer:

- Extremely low energy consumption

- Compact size

- Low total cost of ownership

- Provides dry air – ISO class 3, dew point -20°C

- Protects pipes from freezing in low ambient temperatures

- Compatible with all types of screw compressors (oiled, oil-free)

- Provides 100% dry compressed air quality across the entire compressor power range (20-100%)

- Operates without desiccant materials that require filtration

- Low maintenance costs

- No additional costs for compressor modification

- Low pressure drop (max. 0.2 bar)

- No post-filter required

- Removable panels for quick access

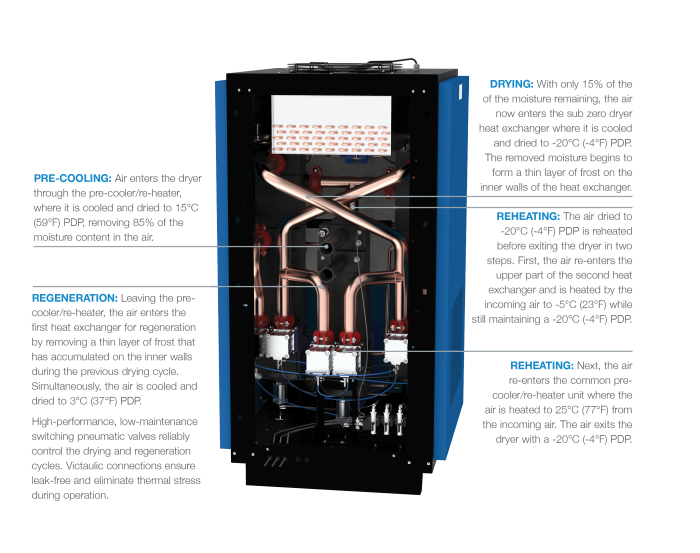

CompAir CMT dryers are the first dryer technology to deliver a dew point of -20°C while reducing energy costs by 70%, combining several technological solutions in one machine. The CMT dryer delivers amazing results with the lowest total cost of ownership (TCO) compared to any other dryer on the market. It is the two-stage design of the dryer that has made such outstanding results possible.

Typical desiccant dryers use upwards of 15% purge air for regeneration, which equates to 15% of the energy cost of the compressor. The CMT dryer does not require purge air, eliminating this wasted energy cost. Smart solenoid drain valves are actuated based on the condensate level to ensure complete drainage removal during each cycle without wasting compressed air.

Operating Stages:

Pre-cooling: Compressed air is cooled to +15°C, which removes up to 85% of moisture.

Regeneration: Air passes through a heat exchanger, where a thin layer of ice accumulated during the previous cycle is removed.

Drying: The air is cooled to -20°C, and the residual moisture freezes on the walls of the heat exchanger.

Reheating: The dried air is reheated to +25°C, maintaining a dew point of -20°C.

Main attributes Refrigeration Dryer Sub Zero CMT266

Reviews about Refrigeration Dryer Sub Zero CMT266

There are no reviews for this product.

Questions and Answers (FAQ) Refrigeration Dryer Sub Zero CMT266

-200x200.jpg)