Description Screw air compressor Gardner Denver ESM110e A34905430

Compressors Gardner Denver series ESM, VS and E range 90-132 kW represent themselves advanced solutions for industrial compression air, developed with consideration most-modern technologies and engineering innovations. These compressor systems provide optimal combination productivity, energy-efficiency and reliability, that makes them ideal choice for enterprises different branches industry.

Screw compressors Gardner Denver in range powers 90-132 kW intended for provision constant, high-quality compressed air with minimal cost ownership. Each model line-up developed not simply as equipment, but as strategic investment in productivity and efficiency production process.

Model row compressors 90-132 kW

ESM series – Screw compressors fixed speed

Series ESM (Fixed Speed Screw Compressors) represents classic screw compressors with constant speed rotation, optimized for stable consumption air. These machines provide reliable work in mode constant load and are ideal solution for enterprises with predictable demand on compressed air.

VS series – Compressors with variable speed

Compressors series VS (Variable Speed) equipped technology regulation speed rotation, that allows effectively adapt to variable demand on air. This technology provides maximum energy-efficiency in whole working range, allowing significantly reduce annual costs on ownership compressor system.

E-series – Compressors premium-efficiency

Models ESM-e represent highest level energy-efficiency in line-up. Thanks integration electric-motor class IE4 and automatic valve regulation oil, these compressors demonstrate leading on market energy-efficiency with advantage up to 2,5% compared with standard models.

Technical characteristics and constructive features

High-efficiency air block (Airend)

Heart each compressor Gardner Denver – this screw element compression own development and production. Air block created with use most-modern equipment, that guarantees premium efficiency and highest quality compressed air. New high-efficiency air block works on low speeds rotation, that minimizes consumption energy and provides excellent productivity throughout whole term exploitation.

Semi-integrated construction air block with built-in oil filter and regulating valve means smaller quantity external components and pipelines. This excludes risk leakage, facilitates maintenance and increases general reliability system.

Innovative construction sealing shaft

Compressors ESM, VS and E equipped innovative construction sealing shaft with protection from failures (fail safe shaft seal). This constructive feature provides highest level quality and reliability work, minimizing risk downtime equipment and providing continuity production process.

High-quality system connections

For increase reliability and simplicity maintenance in compressors used high-quality connections: solid hoses and pipe connections with viton couplings Victaulic. Such system connections provides tightness, durability and simplicity dismantling at conducting technical maintenance.

Automatic lubrication engine

System automatic lubrication engine increases term service bearings and not requires regular maintenance. This reduces operational costs and decreases necessity in manual intervention for support optimal work equipment.

Premium high-efficiency electric-motor

All compressors in range 90-132 kW equipped premium high-efficiency electric motors, which provide optimal conversion electric-energy in mechanical work. Models e-series completed motors class IE4, that represent highest standard energy-efficiency in industry.

Energy-efficiency and economy costs

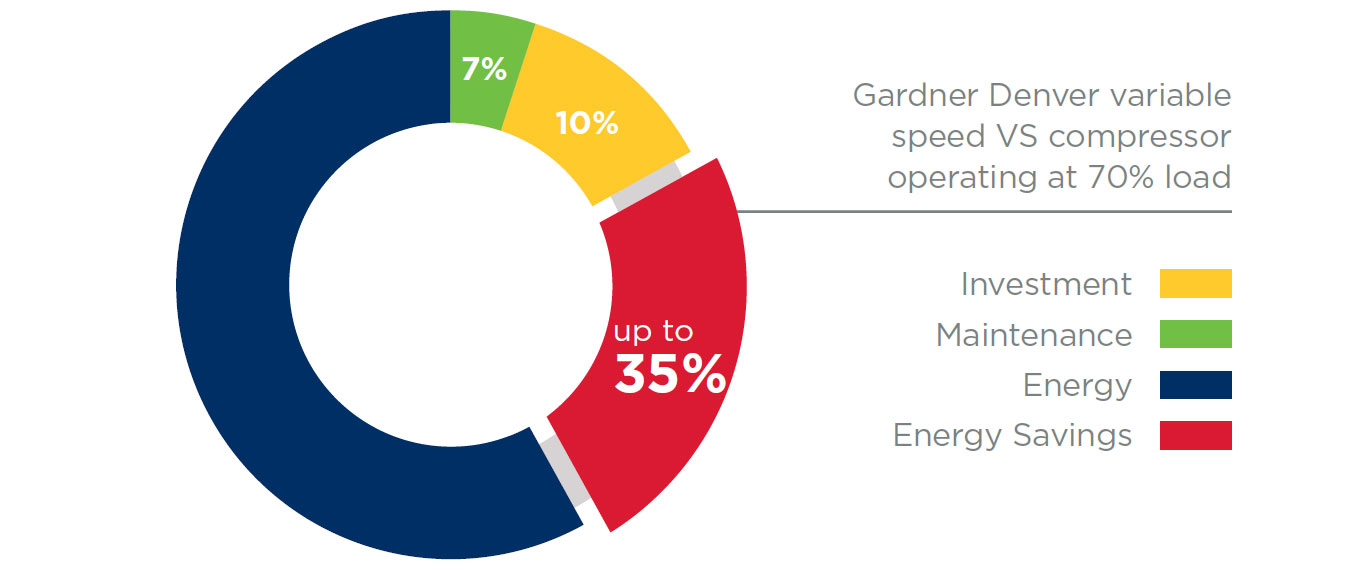

Technology variable speed (VS Technology)

Compressors series VS capable effectively and reliably manage variable demand on air, which characteristic for most production systems. Wide range regulation speed rotation provides absence cycles idle run, that leads to significant economy energy. Construction system engine-drive-air block provides high efficiency in wide range volume flow.

Annual costs on ownership compressor system can be significantly reduced thanks use technology variable speed, since compressor automatically adapts its productivity to real demand, avoiding useless consumption energy.

Premium-efficiency e-models

Models ESM-e demonstrate leading on market energy-efficiency with advantage up to 2,5% compared with standard models. Thanks integration electric-motor IE4 and automatic valve regulation oil, these compressors can save up to 2500 euro per year on costs for electric-energy, that provides quick payback investments.

Increase efficiency on 6%

Sources indicate on achievement lowest operational costs thanks increase efficiency on 6% compared with previous generations compressors. This achieved thanks complex approach to engineering perfection, including optimization all components system.

Innovative valve regulation oil

Specially developed integrated valve regulation oil increases efficiency up to 5% for models with variable speed and premium-efficiency. Besides, this valve contributes prolongation term service lubricant material, reducing costs on its replacement and maintenance.

Integrated recuperation heat

All models compressors range 90-132 kW optionally available with integrated system recuperation heat. Efficient system recuperation allows achieve significant economy energy and costs by way use heat, that generated compressor, for other production needs.

Recuperated heat can be used for:

- Heating hot water for technological needs

- Support temperature in industrial processes

- Heating production or office premises

Such integration allows transform "waste" energy in useful resource, significantly increasing general energy-efficiency production object.

Warranty program Protect 10

Leading in branch warranty

Gardner Denver offers one of most-generous warranty programs in branch compressor equipment – Protect 10 Warranty and Service. This program protects investments clients on term up to 44 000 hours or 10 years, that comes earlier.

Conditions warranty coverage

Warranty program Protect 10 provides differentiated coverage different components system:

Air block (Airend): Warranty on term 10 years or 44 000 hours work. This provides long-term protection most-important component compressor.

Complete installation: Warranty on term 6 years or 44 000 hours work on whole complete set compressor package.

Free warranty

Important advantage program Protect 10 is that, that it provided absolutely free for owner compressor. This means, that clients receive maximum protection their investments without additional financial costs.

Service maintenance

Warranty supported agreement about maintenance Protect 10, that allows exactly plan technical maintenance, budgeting and cost ownership. Authorized supplier services Gardner Denver guarantees professional execution all service works, adhering standards manufacturer.

Conditions preservation warranty

For maximum increase term service and efficiency compressor, and also for support warranty obligations, necessary use original spare parts and lubricant materials Gardner Denver. Use non-original components can lead to loss warranty and reduction productivity equipment.

Reliability and durability

Reduced quantity external components

Construction compressors ESM, VS and E provides minimization quantity external components and pipelines. This not only simplifies maintenance, but and reduces probability failures, excludes risk leaks and increases general reliability system.

Synthetic lubricant AEON™ 9000 SP

As standard in all compressors used synthetic lubricant AEON™ 9000 SP, specially developed for maximum protection internal components. This high-tech lubricant provides optimal conditions work, prolongs term service equipment and reduces frequency necessary replacements lubricant material.

Reduced quantity moving parts

Engineering philosophy Gardner Denver provides minimization quantity moving parts in construction compressor. This directly influences on reliability equipment, since each moving part is potential source wear and failures. Smaller quantity moving components also reduces costs on technical maintenance.

Easy access to points maintenance

Construction compressor packages provides easy access to all points maintenance. This reduces time, necessary for conducting technical maintenance, and allows perform most operations without full dismantling equipment.

Systems control and monitoring

Controller GD Pilot TS

Innovative controller GD Pilot TS with touch screen high resolution is basis system management compressor. Controller extremely convenient in use thanks intuitive interface, where all functions clearly structured in five main menus.

Main possibilities GD Pilot TS:

- Multilingual interface for convenience exploitation

- Home page with instant overview state compressor

- Clock real time for programming modes work

- Possibility installation second installation pressure

- Integrated management systems cooling and dryer

- Journal history faults for deep analysis

- Remote control through programmed inputs

- Automatic restart after failure power

- SD-card for storage working characteristics

Monitoring and analytics

Controller GD Pilot TS provides constant monitoring working parameters, that is critically important for reduction operational costs. System displays detailed analysis in form diagrams trends and graphs, allowing exactly tune working parameters for maximization efficiency.

Parameters, that monitored:

- Pressure in air line/network

- Speed rotation engine (for models VS)

- Hours work under load and general quantity worked hours

- Average volume flow

- Average weekly volume flow

System iConn – Solution Industry 4.0

All compressors series ESM, VS and E standard equipped system iConn – intelligent service monitoring in mode real time. This system is embodiment concept Industry 4.0 in compressor technologies.

Functional possibilities iConn:

- Generation analytical data and statistics productivity

- Predictive maintenance (predictive maintenance)

- Detection potential problems to their emergence

- Exact planning production

- Monitoring on basis state equipment

- Optimization control full air production

- Integration external templates data

System iConn provides full peace and protection investments, allowing avoid expensive unscheduled downtime and unplanned repairs. This achieved thanks possibility system predict potential problems on basis analysis current data and historical trends.

Controller GD Connect 12 Plus

For complex systems, that include several compressors, where general power machines exceeds maximum demand, necessary centralized controller GD Connect 12 Plus. This system management is critically important for provision work whole compressor system on highest level efficiency.

Controller optimizes work several compressors, distributing load such way, to provide maximum energy-efficiency system in whole and minimize wear separate units equipment.

Quality compressed air and systems cleaning

High-efficiency internal filtration

Compressors Gardner Denver series ESM, VS and E equipped high-efficiency two-stage separator filter, which provides supply in system air highest quality. Thanks this advanced system filtration, level carryover oil (oil carryover) constitutes less 3 ppm (parts on million), that corresponds high standards quality for most industrial applications.

Capacity separator equipped flip cover for facilitation maintenance, that allows quickly and conveniently conduct replacement filtering elements without necessity use special instrument.

Complex range equipment for cleaning air

Gardner Denver offers full assortment equipment for processing compressed air, that provides highest quality final product and efficient work whole system:

Base equipment for cleaning:

- Water-cyclone separator for primary removal condensate

- Filters compressed air different classes cleaning

- Condensate drains for automatic removal condensate

Systems drying air:

Gardner Denver offers different types dryers for correspondence specific requirements production processes:

- Refrigeration dryers: Efficient solution for most industrial applications, that provides dew point to +3°C

- Non-regenerative adsorption dryers: For achievement low dew points without use heat

- Adsorption dryers with regeneration heat: Energy-efficient solution for obtaining very dry air

Integrated management systems cleaning

Controller GD Pilot TS has function integrated control dryer, that allows centrally manage as compressor, so and system preparation air. This provides optimal coordination work all components system compression air.

Application and branches use

Compressors Gardner Denver series ESM, VS and E range 90-132 kW are universal solution for wide spectrum industrial applications:

Production industry: Provision pneumatic instruments, systems automation, packaging equipment

Automotive industry: Power conveyor lines, pneumatic systems assembly, painting chambers

Food and pharmaceutical industry: High-quality air for processes packaging, transportation product, management technological processes

Chemical industry: Provision technological processes, instrument air, systems transportation

Textile industry: Power weaving machines, pneumatic transport fibers

Woodworking industry: Provision pneumatic instrument, systems pressing, coating

Service support and original spare parts

Importance use original components

Use original spare parts and lubricant materials Gardner Denver is critically important for support optimal productivity, reliability and energy-efficiency compressor equipment. Original components developed specially for concrete models and provide:

- Minimal losses energy

- Maximum term service equipment

- Preservation warranty obligations

- Correspondence technical characteristics

Professional service maintenance

Authorized service centers Gardner Denver provide professional maintenance on highest level. Technical specialists pass special training and have access to original technical documentation, that guarantees qualitative execution all types works.

Conclusion: Investment in efficiency and reliability

Compressors Gardner Denver series ESM, VS and E range 90-132 kW represent optimal combination advanced technologies, energy-efficiency and reliability. Leading in branch warranty program Protect 10, innovative systems control and monitoring, and also possibility significant economy energy make these compressors strategic investment for enterprises, that strive to optimization production costs and increase competitiveness.

Choosing compressors Gardner Denver, clients receive not simply equipment, but complex solution, that includes advanced technologies, professional support and guarantee long-term efficient work. This provides peace, predictability costs and confidence in continuity production processes on long years exploitation.

Main attributes Screw air compressor Gardner Denver ESM110e A34905430

Reviews about Screw air compressor Gardner Denver ESM110e A34905430

There are no reviews for this product.

Questions and Answers (FAQ) Screw air compressor Gardner Denver ESM110e A34905430