Compressed air with two-stage treatment according to ISO 8573 1.2.1 is an important feature of freezing and storage technology

Compressed air with two-stage treatment according to ISO 8573 1.2.1 is an important feature of freezing and storage technology

In 2023, Compressors International was involved in the creation of new production facilities producing frozen products for Ukraine and the EU. We have supplied a full range of compressor equipment that will help to produce a very high quality product. This experience is important to us as it influences the development of the use of compressor equipment in the Ukrainian market. Here is a description of the processes that take place in such a production facility using Gardner Denver compressor equipment.

The advantage of shock freezing - the IQF (Individual Quick Freezing) technology - is that it eliminates the formation of large ice crystals, which affect the integrity of the berry tissue. As a result, IQF products retain all of their beneficial properties and taste the same as fresh.

The modern trend towards healthy and high-quality food has given rise to the development of an entire industry, it starting with the fields and farms, through logistics, preparation, sorting, cold storage and packaging of the products, and ending with the shelves of large food supermarkets. All the links work 24×7 to ensure that consumers in Ukraine and Europe get an environmentally friendly and healthy product.

The technology requires efficient sorting and preparation facilities with modern equipment. The availability of high performance automated production lines enables a wide variety of products to be processed and packaged in virtually any type of packaging material. Compressor plants producing high quality compressed air are directly involved in these processes.

Why are the compressed air quality requirements so high and why is compressed air so important to this process? The answer to this question is the use of state-of-the-art automated lines. A modern production complex for picking, sorting, washing and drying fresh berries and fruits before freezing is an automated production facility with a minimum of personnel! This is extremely important today, when there is a serious shortage of labour, and allows us to achieve high standards of product quality.

The answer to this question is the use of state-of-the-art automated lines. A modern production complex for picking, sorting, washing and drying fresh berries and fruits before freezing is an automated production facility with a minimum of personnel! This is extremely important today, when there is a serious shortage of labour, and allows us to achieve high standards of product quality.

The main functions (sorting, drying, calibrating, slicing and packaging) are carried out on automated high-speed lines driven by the pneumatic energy of compressed air. In addition, the high precision of the calibration and slicing processes is the result of the use of high-precision sensors and high-speed blades - where the precision and speed are achieved by using compressed air with a pressure of at least 8 bar and a quality in accordance with ISO 8573 Class 1.3.1, i.e. the air used is 100 times cleaner and 145 times drier than ambient air! It is this quality of compressed air that enables the precision and quality of the work processes and, ultimately, the products.

High quality compressed air is a very expensive energy-intensive product: the cost per 1000 m3 of air (compressed to 8 bar and dried to a dew point of -40°C according to ISO 8573 Class 1.2.1) is 105 kWh = 572.25 UAH (approx. EUR 14.7).

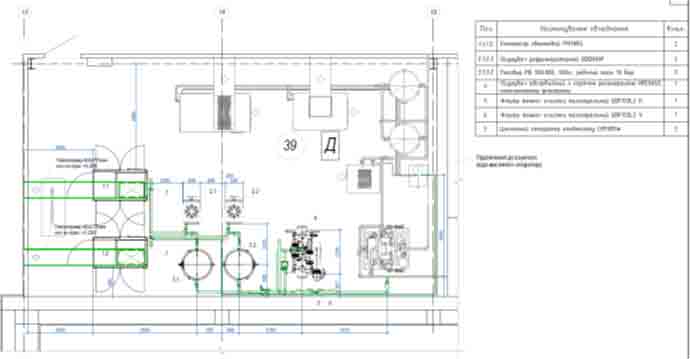

This is why the compressor station uses the most advanced energy-saving systems: variable speed compressors controlled by frequency converters (RS technology by Gardner Denver) can save up to 35% of total energy costs. These compressors have the highest energy efficiency class A+ and allow the reuse of the electricity consumed in the form of heat at a temperature of 50-85°C.

This heat can in turn be used for domestic purposes, such as heating water or rooms in winter (heat recovery), thereby reducing overall production costs.

This heat can in turn be used for domestic purposes, such as heating water or rooms in winter (heat recovery), thereby reducing overall production costs.

For this type of production, two-stage deep air drying technology is of paramount importance. The technology uses sequential drying with the cycling refrigeration dryer with filtration, followed by the heated

blower desiccant air dryer.

After such a deep and consistent dehumidification system, the compressed air has only 0.119 g of moisture/m3, which corresponds to a dew point of -40°C.

Combined two-stage dehumidification combines the advantages of refrigeration technology (minimal energy consumption) and adsorption technology (Class 2 deep dehumidification according to ISO 8573). In addition, two-stage dehumidification has the lowest TCO (Total Cost of Ownership) because the most expensive consumable (molecular sieve adsorbent) is used without moisture overload in the off-season and lasts up to 8-10 years without replacement. This is 2-3 times longer than single stage dehumidification and represents a significant cost saving.

.jpg) After packing and packaging, the finished frozen products are delivered to the warehouse (which has more than 10,000 pallet spaces) where they are stored at a temperature of -20°C, which is optimal for storing the finished product. From here, the product is shipped to Ukrainian stores and exported to consumers in more than 20 countries around the world, as the production is BRC Food Certified.

After packing and packaging, the finished frozen products are delivered to the warehouse (which has more than 10,000 pallet spaces) where they are stored at a temperature of -20°C, which is optimal for storing the finished product. From here, the product is shipped to Ukrainian stores and exported to consumers in more than 20 countries around the world, as the production is BRC Food Certified.

The BRCGS Global Food Safety Standard is recognised by food manufacturers around the world. Certification to this standard confirms a company's compliance with the following quality systems HACCP (Hazard Analysis and Critical Control), Good Manufacturing Practice, Good Hygiene Practice and Good Laboratory Practice.

The company's high production standards are made possible by process automation and control, as well as process machinery, including a powerful high-efficiency compressor, dehumidifiers, receivers and a monitoring system from Gardner Denver.