Description Lubricated Rotary Screw Compressor L45 A34905515

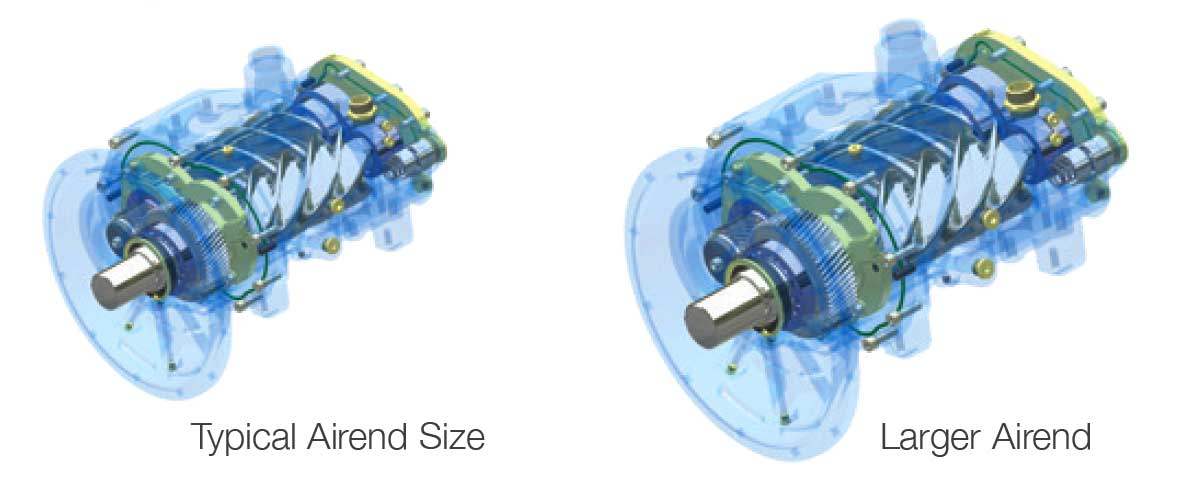

- High efficiency and productivity: The new, enlarged German-made airend provides increased productivity by 8% and energy savings of up to 6% compared to standard models.

- Energy-efficient IE4 electric motor:

The premium IE4 class electric motor as standard provides energy savings and reduces CO₂ emissions. - Quick and easy maintenance:

The semi-integrated design of the airend and the optimized arrangement of components such as the separator and filters allow for quick and convenient maintenance.

Main advantages of the new generation

Enlarged airend in E-models

- Larger German-made air unit

- Increased inlet and outlet sizes for improved airflow

- Reduced pressure drop due to optimized design

- Up to 6% energy savings compared to standard models

- Extended service life due to reduced rotor speed

Savings that pay back in less than 12 months

- Up to 8% efficiency increase compared to standard models

- 8% increase in consumption air with the same engine power

- Additional investment costs pay off in 12 months in most cases

- Significant reduction in total cost of ownership due to reduced energy consumption

Innovative features

- Enlarged plate heat exchanger

Provides optimal cooling and low operating temperature of the equipment. - New generation separator-filter

Enhanced two-stage filtration ensures consistently high quality compressed air (oil content less than 3 ppm). - Thermostatically controlled fan

A thin and highly efficient fan allows the compressor to be installed in production rooms without additional noise insulation. - High-quality connections

Reliable Viton Victaulic couplings provide strength, ease of maintenance and durability.

Technology CompAir RS - Adjustable speed

The compressors of the CompAir RS series are equipped with innovative variable speed engine technology, which provides automatic adjustment of compressor performance depending on the actual compressed air consumption at the enterprise.

Conventional compressors with fixed speed constantly operate at full capacity, regardless of whether this corresponds to the actual production demand. In such cases, excess air is simply wasted, and energy consumption remains high. In contrast, RS series compressors are able to smoothly change the motor speed and capacity over a wide range, thus avoiding unnecessary on-off cycles of the equipment.

Due to the absence of frequent start-stop cycles of the equipment, wear on the compressor components is significantly reduced and its service life is extended. In addition, this system allows you to save up to 35% of energy, reducing maintenance costs and making CompAir RS compressors the optimal solution for companies with fluctuating compressed air demand.

How energy saving works:

- Idle shutdown - traditional compressors consume up to 40% of energy when idling

- Automatic capacity adjustment according to actual consumption

- Wide adjustment range without on/off cycles

- Perfect integration of motor, drive and screw unit

Advantages of RS models:

- Energy savings up to 25% at variable load

- No cycling = significant energy savings

- High efficiency over a wide flow range

- Perfectly tailored to individual needs

Heat recovery - Turning costs into savingsю

What is heat recovery?

When a compressor is running, a significant amount of heat is released that would normally be lost. CompAir's integrated heat recovery system allows you to efficiently use this thermal energy, turning it into a useful resource for your business.

The recovery system can be supplied as a factory solution or installed as an additional retrofit kit that includes all the necessary piping and fittings. Thanks to this solution, the heat generated during the compressor operation can be used for:

- Heating hot water for technological and economic needs;

- Heating production facilities;

- Other production processes that require a constant supply of heat.

Thus, the enterprise receives significant savings on heating and water heating costs, while reducing overall operating costs and improving energy efficiency of production.

Investments in an integrated heat recovery system can pay off within the first year of operation, which makes this solution profitable not only from an economic but also from an environmental point of view.

Application of recovered heat:

- Heating of premises - industrial workshops, warehouses, offices

- Water heating - for technological processes and domestic needs

- Drying of products - in the food, woodworking industry

- Preheating - for boilers and heat exchangers

Economic benefits:

- Reduction in heating costs up to 70%

- Temperature of recovered heat up to 90°C

- System payback usually 2-4 years

- Reduction CO2 emissions and environmental impact

Design and reliability

Premium screw unit of our own production

- Made in Germany class for standard models

- Reliable operation in a wide temperature range

- Quiet fan with thermostatic control

Exceptional reliability and performance

- Large-surface aftercooler - optimal cooling

- New generation separator filter - oil removal less than 3 ppm

- Thermostatically controlled fan - effective and quiet cooling

- High-quality connections - vibration-resistant couplings for reliability

Energy efficiency and reliability

Thanks to advanced technologies and an enlarged screw block, CompAir L30–L45 compressors have high efficiency and reliability. Built-in control and cooling systems ensure stable operation even under heavy load conditions.

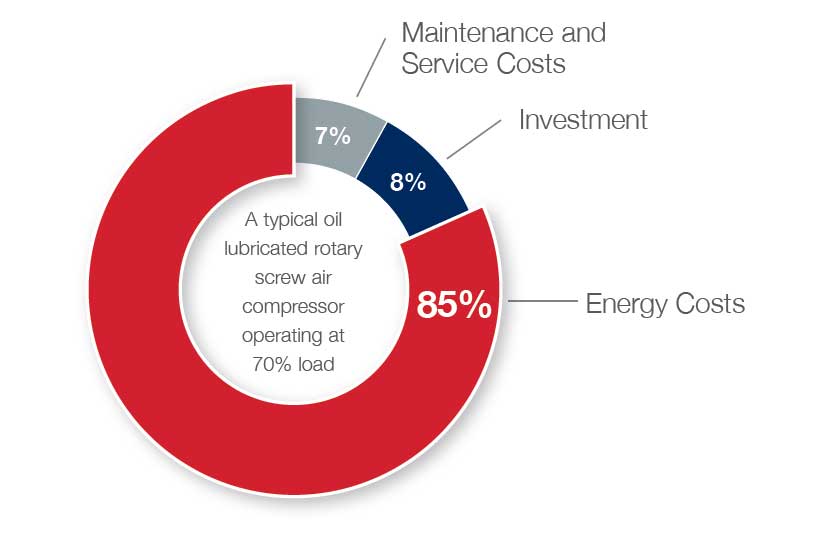

An investment that quickly pays off

The models of the L series with the “e” mark are equipped with an enlarged screw block (airend) with an optimized rotor rotation speed, thanks to which electricity savings reach 9%.

In a period of significant growth in energy prices, choosing CompAir compressors becomes the most justified decision. After all, the largest component of the cost of operating a compressor is electricity, so reducing its consumption significantly affects the total cost of ownership of the equipment.

In a period of significant growth in energy prices, choosing CompAir compressors becomes the most justified decision. After all, the largest component of the cost of operating a compressor is electricity, so reducing its consumption significantly affects the total cost of ownership of the equipment.Investments in these highly efficient compressors pay for themselves in less than 12 months, and the enlarged screw unit has an extended service life.

In addition to saving money, the new premium-classFrame3e compressors allow you to reduce CO₂ emissions by 15tons annually, which is equivalent to the mileage of an average gasoline car over a distance of over 53,000 kilometers.

The new Delcos XL SE7 controllerInnovative touch control

- 7-inch high-resolution display

- Intuitive interface with 5 main menus

- Multilingual support including Ukrainian

- Integrated web server for remote control

Main functions:

- Home page - instant overview compressor status

- Real-time clock - pre-set start/stop

- Second pressure setting - flexible mode control

- Integrated cooling and dryer control

- Fault log - for in-depth analysis

- SD card - stores operating characteristics

- iConn support - remote monitoring

Easy maintenance and service

Design for quick service

- Semi-integrated design of the screw unit

- Optimized service parts - separator and filters

- Quick replacement of cartridges during scheduled maintenance

- Minimal maintenance requirements due to the absence of pistons

Genuine CompAir service kits

To maintain maximum performance and reliability, it is recommended to use only original spare parts and service kits CompAir:

Model

Part Number

Kit Description

L30–L45 / VS (V5)

CK8140-3-N

Basic Kit (requires CK4 Kit)

L30e–L45e / VS (V5)

CK8174-1-N

Basic kit (requires CK4 kit)

L30–L45e, RS

CK2140-3

Standard filter kit (air/oil)

L30–L45 (V5)

CK4140-4-EK-N

4000 service kit hours

L30–L45e (V5)

CK4174-1-EK-N

4000 hours maintenance kit

L30–L45e, RS (V5)

CK4174-1-RS-EK-N

4000 hours maintenance kit

L30–L45, RS

CK4140-4-RS-EK-N

4000 hours maintenance kit

L30–L45

SCWOBG2-5

Screw Warranty Oil Fluid Force, 5 l

L30–L45

SCWOBG2-20

Screw Warranty Oil Fluid Force, 20 l

L30–L45

A92130520

CompAir AEON S oil, 5 l

L30–L45

A92130530

CompAir AEON S oil, 20 l

The use of original CompAir components guarantees trouble-free and economical operation of the compressor station.

Warranty oils

- Fluid Force - synthetic oil for maximum protection

- AEON S - high-quality oil for standard applications

- Available volumes: 5l and 20l

Application

Ideal for:

- Manufacturing enterprises - automotive, food, pharmaceutical industries

- Aerospace industry - tire inflation, painting, welding

- Military industry - pneumatic targets, simulators

- Electronics - PCB cleaning, pick-and-place machines

- Petrochemicals - process air, material flows

- Medicine - process air, vacuum packaging

Benefits of choosing CompAir

Why a screw compressor?

- No valves and mechanical imbalance forces

- High-quality air at high speeds with high flow

- Compact design without compromisesev on productivity

- Reduced maintenance - no pistons, rings, rods

- Low noise and vibration - minimum moving parts

- Continuous operation - no cycle limits

Advantages of a lubricated compressor:

- Full automation through the Delcos controller

- Precise lubrication at the right time

- No manual intervention

- Minimal downtime thanks to the reliable design

- Quick maintenance - cartridge replacement with 4000/8000 hours

Components and options

Basic equipment:

- Compressor with premium screw unit

- Delcos XL SE7 controller

- High-efficiency IE3/IE4 motor

- Integrated oil separator

- Thermostatic cooling system

- Factory filling with lubricant

Additional options:

- Integrated drying system - refrigerated dryer

- Air receiver - different volumes for pressure stabilization

- Recovery system heat - for models from 15 kW

- iConn - remote monitoring and diagnostics

- Extended warranty - additional investment protection

Why CompAir?

Over 200 years of innovation

- Own production of screw units in Germany

- Center of Excellence in Zimmern

- Continuous development of compression technology

- Network of service centers around the world

Warranties quality:

- Extended warranty on the screw unit up to 44,000 hours

- Assure coverage for maximum protection

- Local service support in Ukraine

- Original spare parts for stable operation

Economic benefits:

- Reduction in energy consumption up to 25% with RS technology

- Savings on heating up to 70% with heat recovery

- Increase in efficiency by 8% in E-models

- Payback period less than 12 months under typical conditions

Life cycle cost structure:

- Energy consumption: 75-80% of total costs

- Maintenance: 10-15%

- Initial investment: 10-15%

CompAir L30-L45 - the right choice for enterprises that value efficiency, reliability and economy!

Main attributes Lubricated Rotary Screw Compressor L45 A34905515

Reviews about Lubricated Rotary Screw Compressor L45 A34905515

There are no reviews for this product.

Questions and Answers (FAQ) Lubricated Rotary Screw Compressor L45 A34905515