Description Oil-free rotary screw compressor CompAir D22H W RS A35004110 variable speed

Oil-Free Rotary Screw Compressors CompAir DH: 100% Air Purity, Meeting the Strictest Quality Standards

Compressors series DH from CompAir – a revolutionary solution in the world of compressed air, designed for ensuring absolutely pure, oil-free air without any impurities. These models completely exclude presence of oil in any part of compressor and are certified to ISO 8573-1 Class Zero (2010) standard, also free from silicone. This means full absence of pollution risk, making them indispensable for industries where air purity is critical for product quality and safety of processes. Imagine a production where even smallest drop of oil can spoil batches of medicines, food products, or electronic components – DH eliminates this threat forever.

With over 90 years of experience, CompAir, as a manufacturer and supplier of oil-free compressors, is dedicated to quality, innovation, and understanding client needs. Series DH is developed with consideration of operational and business requirements, helping industries such as food, beverages, pharmaceutical, electronic, medical, and energy to achieve and exceed quality and productivity goals. Moreover, CompAir focuses on environmentally friendly solutions, assisting clients in responding to legislative challenges regarding climate change – from reducing energy bills and increasing efficiency to decreasing carbon footprint.

Advantages of Use: Pure Air Without Risks

Water injection provides oil-free, silicone-free compressed air, becoming a safe energy source for production lines in electronics, chemistry, pharmaceutics, food, and beverage industries. Often air directly contacts with product, thus its purity must be absolute. Series DH achieves this thanks to advanced features, making it a market leader:

- Single-stage direct drive compression element maximizes efficiency and minimizes maintenance, eliminating losses in energy transmission.

- High-quality water injection lubricates, cools, and seals the compression process, increasing efficiency and extending service life.

- Absence of gearbox excludes need for oil lubrication, simplifying design and reducing costs.

- Low loads on bearings and low speeds allow using sealed-for-life bearings without oil, ensuring reliability.

- Regulated speed technology (RS-models) is available for optimizing energy consumption, adapting operation to real needs.

- Comprehensive control with remote connection capability guarantees safe operation and integration into smart systems.

- Fully packaged noise-insulated housing reduces noise to a minimum (from 60 dB) and simplifies installation, making the compressor ready for work "out of the box".

These compressors are not just equipment – they are an investment in business stability. In industries where pollution can lead to huge losses, DH offers guaranteed purity, confirmed by certification. For instance, in pharmaceutics, pure air prevents contamination of medicines; in the food industry, it prevents spoilage of products; and in electronics, it prevents damage to sensitive components. Choosing DH, you receive not only technology but also peace of mind, knowing your process is protected from risks.

Design and Advanced Compression Technologies from CompAir

Series DH – embodiment of advanced compression technology, where complete absence of oil eliminates issues of polluted air. No oil – no risks. Unique design combines low speeds (up to 3500 rpm) with low operating temperatures (less than 60°C), leading to high efficiency and reduced wear of components. Single-stage direct drive without gears or belts maximizes efficiency, while regulated speed adapts air supply to demand, avoiding wasteful energy costs.

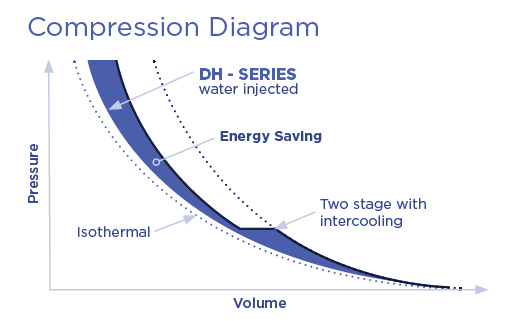

Compressors DH have significantly fewer moving parts than analogues, reducing the likelihood of breakdowns. Low speeds and balanced loads on bearings extend the service life of the compression element, making operation economical. Low temperatures provide nearly isothermal compression, eliminating the need for an internal aftercooler and minimizing pressure losses, which reduces energy consumption. The compression diagram illustrates the advantage: water injection makes the process more efficient than in two-stage systems with an intercooler, saving energy.

Loads on compression are balanced: axial forces act from both sides of the rotor, radial forces from top and bottom, ensuring the highest reliability. A water purification system based on reverse osmosis supplies high-quality water for lubrication, sealing, and cooling, minimizing its consumption thanks to a permeate pump. This is like an ideal cycle: water is not only effective but also eco-friendly.

Comparative Table: CompAir DH vs. Traditional Two-Stage Oil-Free Compressors

|

Parameter |

CompAir DH |

Traditional 2-Stage Oil-Free Compressors |

|

Presence of Oil |

No |

Yes |

|

Rotation Speed |

Up to 3500 rpm |

6000–25000 rpm |

|

Compression Temperature |

60°C |

Up to 200°C |

|

Number of Compression Elements |

1 |

2 |

|

Number of Gears |

0 |

5–7 |

|

Number of Bearings |

7 |

More than 15 |

|

Number of Seals |

2 |

More than 15 |

This table highlights the advantages of DH in simplicity. Absence of oil eliminates risks, low speeds and temperatures reduce wear and energy consumption, and minimal number of components simplifies maintenance. In DH, components such as oil separator, gearbox, oil filters, aftercooler, oil pump, and complex seals are not needed, reducing costs and increasing reliability. Traditional compressors require more maintenance; DH follows the principle of "less is more," where simplicity is the key to durability.

Components Not Needed in DH-Series Compressors

Series DH – embodiment of minimalism: thanks to water injection and single-stage system, many components are simply unnecessary, making the design more reliable and cost-effective. Here are the key elements absent:

- Oil: Full absence excludes pollution and maintenance, ideal for sensitive industries.

- Oil Separator: Not needed, as there is no oil to separate from air.

- Gearbox: Without gears, the design is simpler, with no losses on lubrication.

- Oil Filters: Absent, reducing replacement costs.

- Aftercooler: Low temperatures eliminate the need, minimizing pressure losses.

- Oil Pump: Not required without oil.

- Complex Seals: Only 2 simple seals compared to more than 15 in traditional models.

This simplifies operation, reduces breakdown risks, and cuts costs. DH focuses on the essence – effective compression without excess.

Regulated Speed Technology: Maximum Efficiency and Savings

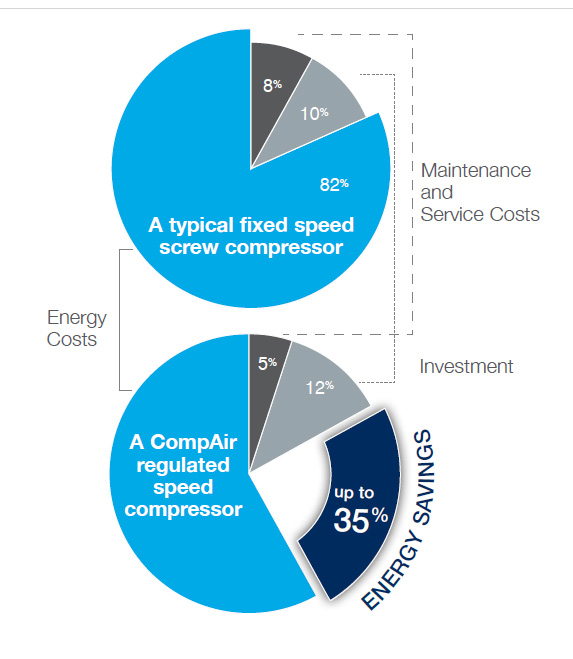

Series DH-RS is equipped with the effiDRIVE system, exceeding class IES2 EN61800-9, ensuring energy savings across a wide range. A wide regulation range excludes cycles, saving energy. Compressors adapt to variable demand, maintaining constant pressure and saving up to 35%. This is like a smart engine: it works only at required power.

The largest compressor expense is energy (82%). DH minimizes it: fixed speed consumes excess, regulated speed uses only what is necessary. A pie diagram shows: energy 82%, investments 10%, maintenance 8%. With DH, you save on everything.

Delcos XL Controller: Innovative Management

The touch Delcos XL controller with a multilingual interface ensures reliability, monitoring parameters to reduce costs.

Accurate monitoring includes pressure/temperature of the environment, input/output, water level, etc. High-resolution screen, SD-card for analysis, trends (pressure, speed, hours, flow). Optional sequential control.

This is not just a controller – a tool for optimization, protecting investments and reducing risks.

Air Processing and Condensate Management: AirPlus

Modern production requires pure air. CompAir offers: cyclone separators, filters, condensate drain, refrigerated/desiccant dryers (without heating, with heating, HOC), subfreeze dryers, nitrogen generators. This ensures 100% compliance with standards.

Investment Protection: Assure

A service contract and warranty prevent downtime. Benefits include: lower cost, quality service from specialists, increased availability, efficiency, extended warranty. This means peace and savings.

iConn: Predictive Maintenance 4.0

iConn – standard for DH: real-time monitoring, data analysis, forecasting, efficiency optimization, downtime reduction. Free on new units, upgrade possible.

Original spare parts: long-term use, minimal losses, high reliability.

Technical Specifications

Pressure: 5-10 bar. Flow: 0.32-6.87 m³/h. Power: 15-37 kW.

Fixed Speed (Air/Water):

- D15H: 15 kW, 8/10 bar, 2.30/1.80 m³/h, noise 68/65, weight 672/624 kg.

- D22H: 22 kW, 3.50/2.89, 68/65, 691/643.

- D37H: 37 kW, 5.86/5.04, 71/61, 960/860.

Variable:

- D15H RS: 15 kW, 5-10 bar, 0.32-2.34, 67/64, 687/639.

- D22H RS: 22 kW, 0.68-3.45, 67/64, 687/658.

- D37H RS: 37 kW, 1.09-6.87, 71/60, 995/895.

Main attributes Oil-free rotary screw compressor CompAir D22H W RS A35004110 variable speed

Reviews about Oil-free rotary screw compressor CompAir D22H W RS A35004110 variable speed

There are no reviews for this product.

Questions and Answers (FAQ) Oil-free rotary screw compressor CompAir D22H W RS A35004110 variable speed