Description Screw air compressor Gardner Denver ESM200FC A349065065

Revolutionary technology FourCore – future industrial compression air

Compressors Gardner Denver series ESM/VS 110FC – 290FC with technology FourCore represent innovative solution for enterprises, which strive maximum energy-efficiency and optimization production space. Patented technology FourCore, developed in center advanced excellence Gardner Denver in Germany, provides best in class performance for oil-lubricated rotary-screw compressors.

What such technology FourCore?

FourCore ("power 4!") – this unique system two-stage compression air premium-class, which combines efficiency two-stage compressor with compactness single-stage unit. Heart technology – innovative air-end with 1 engine and 4 rotors, integrated in single semi-integrated cast housing.

Key advantages compressors with technology FourCore

Unsurpassed energy-efficiency

Compressors FourCore provide improvement efficiency on 8-10% compared with usual single-stage compressors:

- Two-stage compression premium-class – maximum efficiency at minimal energy-costs

- Low speed rotation air-end – minimizes consumption electricity

- Unique configuration 2-stage drive mechanism – supports constant intermediate pressure for optimal efficiency

- Payback investments less than in year in many cases application

- Significant saving operational costs throughout whole term operation

Ultra-compact design

Technology FourCore offers one of smallest overall dimensions on market two-stage oil-lubricated compressors:

- Size single-stage unit at efficiency two-stage compression

- Very small weight – simplifies installation and transportation

- Semi-integrated cast housing – reduces quantity external components

- Minimum pipelines and hoses – saving production space

- Integrated design and reliability

Semi-integration air-end FourCore includes:

- Integrated oil filter and valve regulation oil

- Oil stop valve built-in design

- System distribution oil and valve temperature oil

- Minimization risk leaks thanks smaller quantity connections

- Simplified technical maintenance – easy access to all components

- 10-year warranty on air-end (up to 44 000 hours work)

Environmental responsibility

Compressors FourCore demonstrate exceptional environmental indicators:

- Reduction emissions CO₂ up to 134 tons on year (model ESM160FC at 8000 hours work)

- Significant reduction energy wastes compared with traditional solutions

- Compliance highest environmental standards industrial equipment

- Contribution in achievement corporate goals sustainable development

Model range compressors with technology FourCore

Series ESM/VS 110FC – 290FC presented in two variants:

ESM (Fixed Speed) – compressors with constant speed

Ideal for stable load with constant need in compressed air

VS (Variable Speed) – compressors with variable speed

Optimal for variable loads with maximum adaptability to needs production

Range powers: from 110 to 290 kW – covers wide spectrum industrial applications

Why choose compressors FourCore?

Comparison with traditional compressors

|

Parameter |

Usual single-stage |

FourCore |

|

Efficiency |

Base |

+8-10% |

|

Dimensions two-stage |

Large |

As single-stage |

|

Quantity components |

More |

Minimized |

|

Risk leaks |

Higher |

Minimal |

|

Maintenance |

More complicated |

Simplified |

|

Warranty on air-end бұ |

Standard |

10 years/44000 hours |

|

Payback |

Longer |

Up to 1 year |

Ideal branches application

Compressors FourCore effective in various industrial sectors:

- Machine-building – provision pneumatic equipment

- Food industry – safe compressed air for production

- Pharmaceutics – reliable and clean air for critical processes

- Automotive industry – high-performance equipment for lines

- Textile industry – stable supply compressed air

- Chemical industry – reliability in complex conditions

- Electronics – precision compression for sensitive productions

Economic efficiency investment

Calculation benefits (example ESM160FC)

- Saving energy: 8-10% from total consumption

- Reduction emissions: 134 tons CO₂/year

- Term payback: less 12 months

- Saving for 10 years: significant reduction operational costs

- Minimal costs on maintenance: thanks integrated design

FourCore – technology future already today

Compressors Gardner Denver with technology FourCore – this not simply equipment, but complex solution for business, which provides:

✅ Maximum energy-efficiency – saving up to 10% electricity

✅ Compactness – two-stage power in dimensions single-stage

✅ Reliability – 10-year warranty and minimum downtimes

✅ Environmental-friendliness – significant reduction emissions CO₂

✅ Quick payback – return investments less than in year

✅ Intelligent management – iConn and GD Pilot TS

Invest in technology FourCore – provide your production competitive advantage through most-efficient compression air on market. Contact to official representative Gardner Denver in Ukraine for receipt detailed consultation and calculation economic efficiency for your enterprise.

Screw compressors Gardner Denver series ESM/VS 160-250 represent themselves advanced solution for industrial compression air with oil lubrication. This model range unites two technological concepts: models ESM with fixed speed and innovative compressors VS with variable speed, that provides maximum flexibility for different production needs.

Technical Characteristics and Range Application

Series ESM/VS covers wide spectrum industrial applications thanks universal technical parameters:

Power and productivity:

- Power engine from 160 to 250 kW

- Range working pressure from 5 to 13 bar

- Volumetric flow from 6 to 47 m³/min

- Available variants with air and water cooling

Examples productivity:

- Model VS290 (250 kW) provides flow from 5.87 to 47.02 m³/min at pressure 5-13 bar

- Model ESM290 (250 kW) guarantees stable flow 47.10 m³/min at 7.5 bar

Such characteristics make compressors Gardner Denver ideal choice for mechanical-engineering, food industry, pharmaceutics, automotive production and other branches, where critically important reliability supply compressed air.

Innovative Technology Compression Element

Own Production Premium-Class

Heart every compressor Gardner Denver — this high-efficiency screw compression element (airend), which company develops and manufactures independently. Use newest machines for grinding rotors with CNC in combination with online laser technology guarantees maximum precision and productivity.

Structural Advantages Compression Element

Low revolutions — high efficiency: Compression element premium-class works on reduced speed rotation, that directly reduces costs on electricity and prolongs term service components.

Innovative design: Compression element includes protected end sealing shaft (fail-safe shaft seal), integrated oil filter and valve regulation oil. Such construction minimizes quantity external hose connections, that increases reliability system and simplifies maintenance.

Unprecedented warranty: On compression elements extends free warranty Protect 10 term to 44 000 hours or 10 years (depending from that, what comes earlier). This testifies about confidence manufacturer in quality and durability equipment.

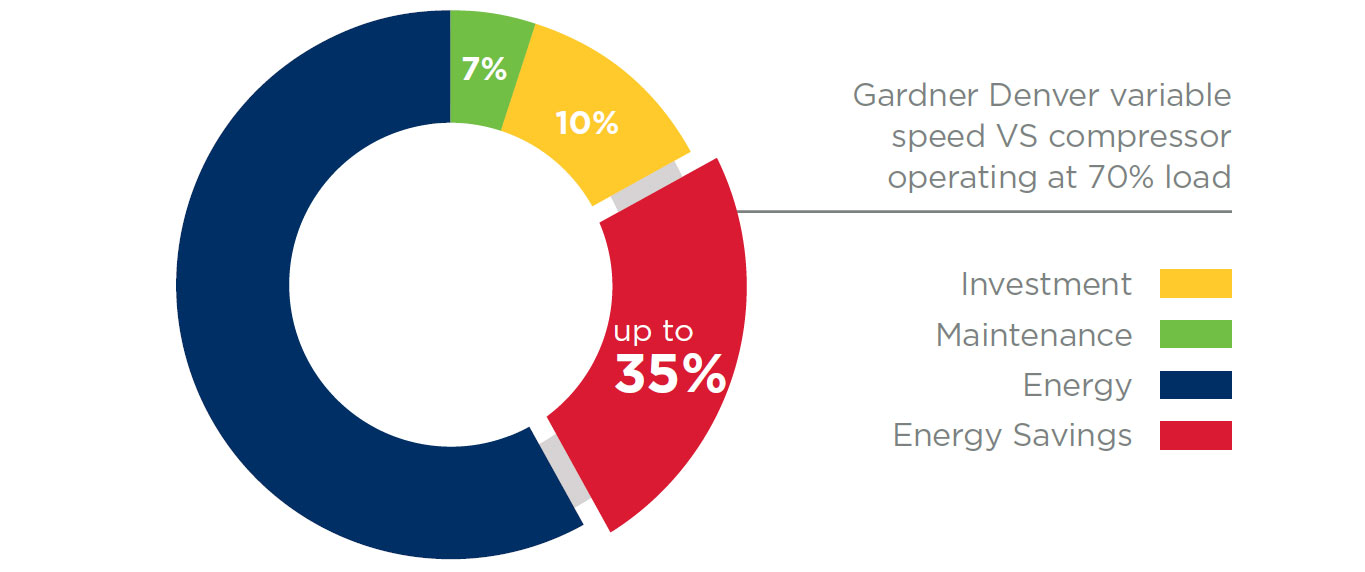

Technology Variable Speed VS: Revolution in Energy-Efficiency

Adaptive Productivity for Variable Demand

Compressors series VS with technology variable speed represent new generation energy-efficient equipment. They ideally suit for enterprises with variable consumption compressed air, automatically adapting productivity to real needs production.

Saving Energy to 35%

Implementation technology variable speed allows achieve saving electricity to 35% compared with traditional screw compressors with fixed speed. Taking into account that, that energy constitutes about 80% total operational costs compressor for five years, such saving provides quick payback investments.

Wide Range Regulation

Compressors VS characterize wide range regulation productivity without cycling, what means:

- Absence starting currents and mechanical loads

- Stable pressure in network without fluctuations

- Minimal consumption energy in mode partial load

- Prolongation term service all components system

Integrated Inverter Concept

Technology frequency converter integrated directly in electrical cabinet compressor with following features:

- Protection from dust by means changeable inlet filters

- Optimized system cooling inverter

- Maximum reliability and long term service

- Ideal configuration "engine-drive-compression element"

Advanced System Cooling

Innovative Concept Separate Cooling

System cooling compressors ESM/VS designed for maximum efficiency and durability components. Air and oil coolers located separately and cooled independently separate radial fans.

High-Efficiency Radial Fans

Thermostatic control: Radial fans equipped thermostatic management, that provides optimal temperature oil and air at any conditions operation.

Low level noise: Specially developed fans with high resistance generate minimal level noise, what important for comfortable working environment.

Large cooling surfaces: Application coolers with large area surface provides lowest achievable temperature air on output, that reduces costs on further processing air.

Inverter Fan: Additional Saving

On models VS inverter radial fan installed standard on oil cooler. For models ESM this option available by order. Regulation speed fan through inverter optimizes temperature mode oil and additionally saves electricity.

Advantages Efficient Cooling

- Prolongation term service compression element and bearings

- Reduction operational costs on dryers and filters

- Stable work at high temperatures surrounding environment

- Minimal costs on technical maintenance

Synthetic Lubricant AEON™ 9000 SP

Unique Chemical Formula

Compressors Gardner Denver equipped synthetic lubricant AEON™ 9000 SP own development. This lubricant specially created for maximization efficiency compressor equipment and provision optimal operational characteristics.

Advantages Synthetic Lubricant

Prolongation intervals replacement: Synthetic base provides stability properties lubricant during long time, what allows increase intervals between replacement.

Protection components: Optimal lubricating ability minimizes wear internal components, including screw pair, bearings and seals.

Energy-efficiency: Reduction internal friction contributes reduction consumption electricity.

Thermal stability: Lubricant preserves its properties at high working temperatures, providing reliable protection equipment.

Intelligent Systems Management and Monitoring

Controller GD Pilot TS: Center Management Compressor

Innovative touch controller GD Pilot TS is brain compressor system, providing full control over all parameters work equipment.

Convenient interface:

- High-resolution touch display

- Intuitively understandable menus and navigation

- Multilingual support

- Five main menus with clear structure

Functions management:

- Instant overview state compressor on main page

- Two independent settings pressure

- Clock real time for programming work

- Integrated management cooling and dryer

- Remote management through programmable inputs

- Automatic restart after failure power

Analysis and optimization:

- Log history faults for detailed analysis

- Diagrams trends working parameters

- Saving characteristics work on SD-card

- Monitoring pressure, speed engine, volumetric flow

- Display average weekly consumption air

These possibilities allow precisely tune working parameters for achievement maximum energy-efficiency and productivity.

iConn: Smart Monitoring Industry 4.0

All compressors series ESM/VS standard equipped system iConn — proactive solution for monitoring in real time, that corresponds concept Industry 4.0.

Predictive maintenance:

- Monitoring on basis state equipment (Condition Based Monitoring)

- Detection potential problems to their critical development

- Recommendations on planned maintenance

- Reduction risk unplanned downtimes

Optimization work:

- Full control production compressed air

- Integration external templates data

- Precise planning production

- Detailed statistics and analytics

Advantages for business:

- Increase time trouble-free work (uptime)

- Reduction operational costs

- Optimization energy consumption

- Deep knowledge about system compression air

GD Connect 12 Plus: Management Compressor Station

For enterprises with several compressors system GD Connect 12 Plus is key instrument energy management and optimization work compressor station.

Possibilities system:

- Management to 12 compressors simultaneously

- Coordination work compressors with fixed and variable speed

- Harmonization working load

- Equalization time running for economic maintenance

Economic advantages:

- Elimination losses energy through narrowing band pressure in network

- Maximization efficiency all compressor station

- Reduction time downtime

- Increase total productivity enterprise

Reliability and Ease Maintenance

Construction for Minimization Downtimes

Compressors ESM/VS designed taking into account convenience maintenance and maximum accessibility all service points.

Compact design:

- Small occupied area (small footprint)

- Optimal use production space

- Possibility installation in limited conditions

Accessibility for maintenance:

- Removable and hinged side doors body

- Easy access to all points maintenance

- Reduced quantity moving parts

- High-quality connections Viton Vitaulic without leaks

Automatic Lubrication Engine

System automatic lubrication provides proper supply lubricant to bearings engine at any time operation. This guarantees:

- Unsurpassed reliability engine

- Prolongation term service

- Reduction costs on maintenance

- Minimization risk premature failure

Original Spare Parts

Use original spare parts Gardner Denver critically important for maintenance high efficiency compressor:

- Long term service components

- Minimal losses and high energy saving

- Guaranteed quality and compatibility

- Preservation parameters productivity

Cost Ownership (TCO): Economic Benefit

Energy: Key Factor Costs

For five years operation energy constitutes about 80% total costs on compressor. Exactly therefore design series ESM/VS maximally focused on reduction energy consumption.

Saving to 35% electricity: Compressors VS with technology variable speed can achieve saving electricity to 35% compared with traditional screw compressors. This provides:

- Quick payback investments

- Significant reduction annual operational costs

- Increase competitiveness enterprise

- Reduction ecological impact

Program Protect 10: Unprecedented Warranty

Gardner Denver offers one of most beneficial warranty programs in branch compressor equipment.

Conditions warranty:

- Compression elements (airends): to 44 000 hours or 10 years

- Total compressor package: to 6 years / 44 000 hours

- Absolutely free for owner compressor

- Full peace and protection investments

Advantages program:

- Precise planning technical maintenance

- Predictable budgeting costs

- Confidence in durability equipment

- Minimization financial risks

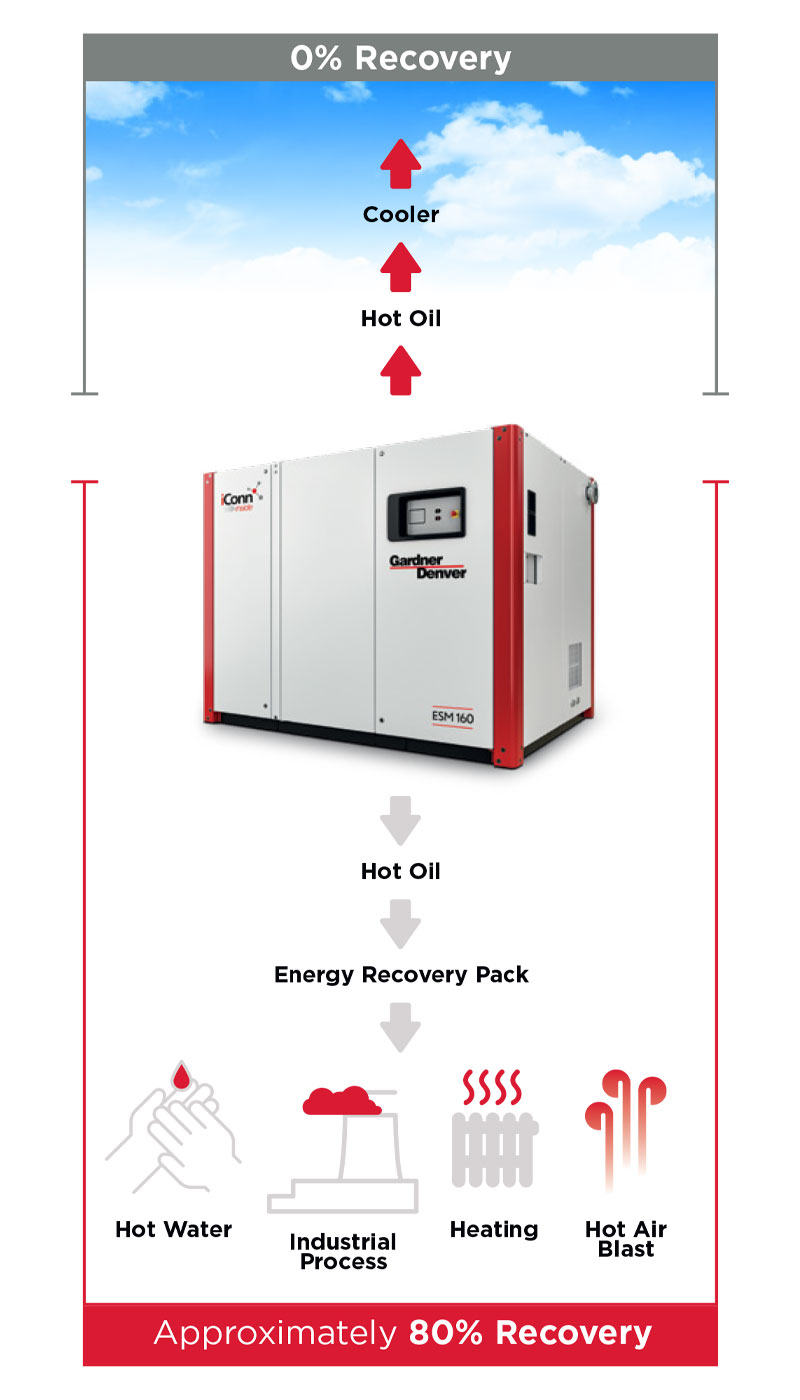

Heat Recovery: Additional Saving

Approximately 80% energy, that consumed compressor, transformed into heat. System recovery heat allows effectively use this energy:

Application recovered heat:

- Production hot technological water

- Systems heating premises

- Preliminary heating water for technological needs

Economic effect:

- Significant saving on heating

- Reduction emissions CO2

- Quick payback system recovery

- Increase total energy-efficiency enterprise

Quality Compressed Air

Internal Systems Cleaning

Although compressors ESM/VS are equipment with oil lubrication, their construction includes elements, that minimize content impurities in air.

Two-stage filtration: High-performance separator filter provides:

- Maximum separation oil from compressed air

- Lower drop pressure in system

- Reduction total operational costs

- Supply air high quality to equipment cleaning

Automatic drain condensate: System zero-loss autodrain installed on cooler air:

- Removal main mass water

- Absence losses compressed air

- Flexibility variants installation

- Reduction load on dryers

Comprehensive Solutions for Cleaning Air

Gardner Denver offers full assortment energy-efficient equipment for further processing compressed air:

Portfolio products:

- Water cyclone separators

- Filters compressed air different classes cleaning

- Systems drain condensate

- Refrigeration dryers compressed air

- Heatless adsorption dryers

- Adsorption dryers with regeneration heat

- Generators nitrogen

This equipment uses newest technologies and provides lowest costs during life cycle, guaranteeing compliance most strict standards quality air.

Application in Different Branches

Versatility for Industry

Compressors Gardner Denver ESM/VS 160-250 found application in wide spectrum industrial branches thanks their reliability, efficiency and flexibility.

Mechanical-engineering:

- Power pneumatic tools and equipment

- Systems management and automation

- Lifting-transport equipment

Food industry:

- Packing equipment

- Transportation bulk products

- Systems cooling and freezing

Pharmaceutical branch:

- Technological processes production

- Pneumotransport raw materials

- Systems control and sterilization

Automotive industry:

- Painting lines

- Assembly robotic complexes

- Pneumatic tools and equipment

Textile industry:

- Pneumatic weaving looms

- Systems transportation fibers

- Equipment for processing fabrics

Ecological Responsibility

Reduction Emissions CO2

Energy-efficiency compressors ESM/VS directly influences on reduction ecological footprint enterprise:

- Saving to 35% electricity means proportional reduction emissions CO2

- Recovery heat additionally reduces consumption traditional energy resources

- Long term service equipment reduces ecological load from production new compressors

Compliance Modern Standards

Compressors Gardner Denver correspond most strict ecological standards and requirements:

- Low level noise for comfortable working environment

- Minimal leaks oil and air

- Efficient use resources

- Possibility full utilization components

Conclusion: Investment in Future

Compressors Gardner Denver series ESM/VS 160-250 represent themselves optimal combination productivity, reliability and economic efficiency. This not simply equipment for compression air — this comprehensive integrated system, which provides:

Technological perfection:

- Own production high-efficiency compression elements

- Innovative technology variable speed with saving to 35%

- Advanced systems cooling and lubrication

Intelligent management:

- Controller GD Pilot TS with intuitive interface

- System iConn for predictive maintenance

- GD Connect 12 Plus for management compressor station

Economic benefit:

- Minimal operational costs thanks energy-efficiency

- Unprecedented warranty Protect 10 (to 10 years / 44 000 hours)

- Possibility recovery to 80% energy in form heat

Reliability and support:

- Ease maintenance and accessibility service points

- Original spare parts with long term service

- Professional support authorized service centers

Choice compressors Gardner Denver ESM/VS 160-250 — this investment in reliable, economic and ecologically responsible future your enterprise. This equipment, which works not simply on your business, but together with your business, adapting to variable needs and providing maximum efficiency during all term operation.

Main attributes Screw air compressor Gardner Denver ESM200FC A349065065

Reviews about Screw air compressor Gardner Denver ESM200FC A349065065

There are no reviews for this product.

Questions and Answers (FAQ) Screw air compressor Gardner Denver ESM200FC A349065065