Description Screw air compressor Gardner Denver ESM23 A34905114B

Gardner Denver ESM and VS series compressors are a premium solution for productions that require continuous supply of high-quality compressed air. Thanks to innovative design, advanced energy-saving technologies and the most generous 10-year warranty in the industry, these compressors set a new standard of reliability and cost-effectiveness in their power class.

Premium screw element design – the heart of the compressor

In-house production for maximum reliability

The screw compression element (Airend) is the heart of any compressor, and that is why Gardner Denver maintains full control over its design and production. The company uses the most modern equipment for CNC rotor grinding in combination with online laser quality control technologies.

Innovative technical solutions

High-efficiency design with slow rotation speed

The screw element provides high performance at reduced engine speeds, which directly affects the reduction of energy consumption. This design ensures an optimal balance between performance and operational cost-effectiveness.

Fail-safe shaft seal and integrated components

The innovative design includes:

- Fail-safe shaft seal that minimizes leakage risks

- Integrated oil filter for continuous lubricant cleaning

- Built-in oil control valve for optimal distribution

These solutions radically reduce the number of external hoses, which not only increases system reliability but also simplifies maintenance and reduces the likelihood of failures.

Premium-class quality connections

The use of durable hoses and pipe connections with Viton Victaulic couplings ensures:

- Increased system reliability under pressure

- Ease of installation and removal during maintenance

- Durability of connections even under constant vibrations

Extended Protect 10 warranty

Screw elements are covered by a unique industry warranty of up to 10 years or 44,000 hours of operation (whichever comes first). This is the best confirmation of the manufacturer's confidence in the quality and durability of its product.

Energy efficiency and advantages of Variable Speed technology

Revolution in energy consumption management

VS Series compressors represent the next generation of air compression technologies, where variable engine rotation speed allows achieving unprecedented levels of energy efficiency.

Savings of up to 35% of energy resources

Adaptation to real demand

Unlike traditional fixed-speed compressors (Fixed Speed), VS models dynamically adjust to current production needs:

- Absence of load/unload cycles means significant electricity savings

- Wide regulation range from minimum to maximum performance

- Efficient operation throughout the entire operating range, not just at full load

High-efficiency IE3 electric motor

All compressors are equipped with energy-saving IE3 class electric motors, which provide:

- Reduced electricity consumption compared to standard motors

- Reduction of CO2 emissions and production's environmental footprint

- Compliance with the strictest European environmental standards

Power Drive System drive system

Advanced technologies for maximum efficiency

VS Series compressors are equipped with a high-efficiency Power Drive System, which:

- Exceeds IES2 class requirements according to EN61800-9 standard

- Provides stable energy savings over a wide performance range

- Ensures smooth regulation without jerks and overloads

Reli |able inverter concept

The variable speed system inverter is integrated directly into the electrical cabinet and features:

- Dust protection with replaceable inlet filters

- Optimized cooling system for maximum reliability

- Increased durability and high equipment availability

Integrated heat recovery system

Significant additional savings can be achieved through the integrated heat recovery system:

- Can be factory-installed or as a retrofit kit

- Allows the use of heat generated during compression for space heating or process needs

- Reduces overall enterprise energy costs

Modern control and monitoring systems

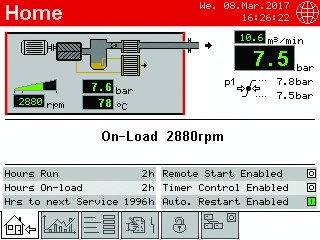

GD Pilot SE controller – intelligent operation management

Convenient graphical interface

The advanced GD Pilot SE control system provides:

- Clear 2.8-inch graphical display with text output

- Modern intuitive user interface

- Access to all key parameters with one touch

Monitoring of critical parameters

The system continuously monitors and displays:

- Discharge pressure and line pressure – for air quality control

- Oil temperature – for overheating protection

- Total operating hours and hours under load – for maintenance planning

- Service required indicator – timely warning of maintenance need

- Extended fault log – detailed history of all events for quick diagnostics

Extended control functionality

GD Pilot SE provides the operator with full control over compressor operation:

- Timer control of stop and start for energy savings during non-working hours

- Remote start/stop for centralized management

- Automatic restart after power failure for uninterrupted operation

- Ability to set a second pressure setting for different operating modes

- Indication of current system status

Integration and communication capabilities

The controller supports modern industrial communication protocols:

- RS485 - Modbus RTU for integration into existing automation systems

- Integrated Web-Server Light for browser access

- Programmable inputs and outputs for controlling additional equipment

- Micro-SD card for long-term recording of emergency signals and operational data

- Integrated BLS functionality for extended capabilities

Industry 4.0 solution – iConn system

Intelligent real-time monitoring

iConn is a revolutionary proactive monitoring system that takes compressor equipment management to a new level:

- Continuous data collection and analysis in real time

- Access to system information from anywhere via the Internet

- Automatic detection of anomalies and potential problems

Predictive maintenance

The iConn system analyzes historical data to:

- Predict possible failures before they occur

- Optimize maintenance schedules

- Maximize intervals between shutdowns

- Reduce unplanned production downtime

Maximizing energy efficiency

iConn continuously monitors energy consumption and helps:

- Identify inefficient operating modes

- Optimize settings for minimum energy consumption

- Analyze consumption trends for long-term planning

- Provide recommendations for efficiency improvement

Availability and implementation benefits

- Free on all new VS23-VS29 compressors

- Possibility of installation on existing compressors (retrofitted)

- Operates as an open standard for easy integration

- Proactive maintenance instead of reactive repair

Technical specifications of models

VS Series compressors with variable speed

Model VS23

Technical parameters:

- Motor power: 22 kW

- Operating pressure range: 5-10 bar

- Capacity (FAD):

- At 7.5 bar: 1.11 – 4.12 m³/min

- At 10 bar: 1.03 – 3.70 m³/min

- At 13 bar: 1.35 – 2.89 m³/min

- Noise level at 70% load: 68 dB(A)

- Weight: 681 kg

- Dimensions (L×W×H): 1345 × 880 × 1612 mm

Model VS26

Technical parameters:

- Motor power: 26 kW

- Operating pressure range: 5-13 bar

- Capacity (FAD):

- At 7.5 bar: 1.11 – 4.78 m³/min

- At 10 bar: 1.03 – 4.10 m³/min

- At 13 bar: 0.92 – 3.56 m³/min

- Noise level at 70% load: 69 dB(A)

- Weight: 708 kg

- Dimensions (L×W×H): 1345 × 880 × 1612 mm

Model VS29

Technical parameters:

- Motor power: 30 kW

- Operating pressure range: 5-13 bar

- Capacity (FAD):

- At 7.5 bar: 1.11 – 5.41 m³/min

- At 10 bar: 1.03 – 4.50 m³/min

- At 13 bar: 0.92 – 3.82 m³/min

- Noise level at 70% load: 69 dB(A)

- Weight: 712 kg

- Dimensions (L×W×H): 1345 × 880 × 1612 mm

ESM Series compressors with fixed speed

Model ESM23

Technical parameters:

- Motor power: 22 kW

- Capacity (FAD):

- At 7.5 bar: 4.16 m³/min

- At 10 bar: 3.45 m³/min

- At 13 bar: 2.98 m³/min

- Noise level: 67 dB(A)

- Weight: 650 kg

- Dimensions (L×W×H): 1345 × 880 × 1612 mm

H4: Model ESM26

Technical parameters:

- Motor power: 26 kW

- Capacity (FAD):

- At 7.5 bar: 4.84 m³/min

- At 10 bar: 4.13 m³/min

- At 13 bar: 3.44 m³/min

- Noise level: 68 dB(A)

- Weight: 677 kg

- Dimensions (L×W×H): 1345 × 880 × 1612 mm

H4: Model ESM29

Technical parameters:

- Motor power: 30 kW

- Capacity (FAD):

- At 7.5 bar: 5.52 m³/min

- At 10 bar: 4.81 m³/min

- At 13 bar: 4.12 m³/min

- Noise level: 69 dB(A)

- Weight: 681 kg

- Dimensions (L×W×H): 1345 × 880 × 1612 mm

Measurement standards

All technical data are measured in accordance with international standards:

- Capacity (FAD): according to ISO 1217, Edition 4, Annex C and E

- Measurement conditions: air temperature 20°C, inlet pressure 1 bar (A), humidity 0%

- Noise level: measured in free field according to ISO 2151, tolerance ±3 dB(A)

Compressed air quality and cleaning systems

Internal air preparation

High-efficiency separator filter

Gardner Denver compressors provide the highest quality compressed air thanks to:

- Two-stage filtration system that guarantees oil carryover less than 3 ppm

- Reliable oil separation from air in all operating modes

- Separator tank with hinged lid for quick maintenance

Enhanced efficiency cooling system

The aftercooler with large surface area provides:

- Optimal cooling of compressed air

- Low operating temperatures for increased reliability

- Reduction of discharge temperature for equipment protection

- Efficient moisture condensation

Thermostatically controlled fan

High-efficiency motor-driven fan:

- Provides extremely quiet operation

- Allows compressor placement directly in the workplace

- Maintains optimal temperature under any load conditions

- Allows maximum air line length without additional equipment

External air treatment portfolio

Modern production processes require the highest standards of compressed air quality. Gardner Denver offers a full range of equipment to bring air to the required parameters:

Water cyclone separators

Efficient separation of condensate and mechanical impurities at the initial air preparation stage.

Compressed air filters

Multi-stage filtration system for removal of:

- Solid particles of various sizes

- Oil residues and aerosols

- Odors and vapors

Condensate drain system

Automatic condensate removal without compressed air losses, ensuring:

- Stable air quality

- Equipment protection from corrosion

- Environmentally friendly condensate disposal

Refrigerant dryers

Air cooling to reduce dew point and provide:

- Dry air for pneumatic tools

- Protection from condensation in air lines

- Energy-efficient operation with minimal costs

Adsorption dryers

For the highest air quality requirements:

- Heatless dryers – for stable operation without additional energy

- Heat-regenerated dryers – for maximum energy efficiency at large volumes

Nitrogen generators

On-site nitrogen production for processes requiring an inert atmosphere.

Comparison of ESM and VS technologies

Key differences for optimal choice

ESM series – fixed speed stability

Ideal application conditions:

- Productions with constant compressed air demand

- Processes with uniform load throughout the work shift

- Facilities where operational predictability is more important than flexibility

Advantages:

- Simple and reliable design

- Easy maintenance

- Predictable energy consumption

- Lower initial cost

VS series – intelligent demand adaptation

Ideal application conditions:

- Productions with variable compressed air demand

- Processes with uneven load

- Facilities with high energy efficiency requirements

- Systems with partial load for a significant time

Advantages:

- Energy savings up to 35% compared to fixed speed

- No load/unload cycles

- Extended service life due to smooth operation

- Possibility of iConn system upgrade

- Optimal efficiency across the entire performance range

Operating cost distribution

Compressor ownership cost structure:

- Energy: 83% – the largest cost share, where VS technology provides maximum savings

- Maintenance: 10% – regular support costs

- Investment: 7% – initial equipment cost

Maintenance and operation

Compact design for easy installation

Space optimization

All ESM and VS series models have identical compact dimensions:

- Small footprint reduces installation area requirements

- Unified dimensions simplify equipment replacement or upgrade

- Possibility of installation in limited production spaces

Easy access to maintenance points

Thoughtful design ensures:

- Fold-down and removable side cabinet doors

- Full access to all maintenance points

- Convenient location of control and measuring instruments

- Minimum time for technical maintenance

Reduced maintenance costs

Minimized number of moving parts

Engineering excellence of the design:

- Reduced number of wear components

- Extended intervals between maintenance

- Lower cost of spare parts

- Reduced downtime for technical maintenance

Gardner Denver original spare parts

Use of original components guarantees:

- Long service life even in the harshest operating conditions

- Minimum losses for additional energy savings

- High reliability and maximum uptime

- Strict quality control at all production stages

Protect 10 program – the best warranty in the industry

Unique warranty coverage conditions

Gardner Denver offers one of the most generous warranties on the market:

- 10 years or 44,000 hours on the screw compression element

- 6 years or 44,000 hours on the entire compressor unit

- Warranty valid from the earlier date

Benefits for the owner

- Completely free program for the compressor owner

- Guaranteed service quality from authorized service partners

- Accurate planning of maintenance costs and budgeting

- Maximum investment protection

Warranty retention conditions

To maintain full warranty, it is necessary to:

- Use Gardner Denver original spare parts and lubricants

- Perform maintenance at authorized service centers

- Follow recommended technical maintenance intervals

- Use the compressor in accordance with technical specifications

Additional features and upgrades

GD Connect multi-compressor control system

Optimization of compressor station operation

For enterprises with multiple compressors combined into a common network, the centralized GD Connect control system is critically important:

- Coordination of all compressors for maximum efficiency

- Automatic load distribution between units

- Ensuring system operation at the highest efficiency level

- Preventing simultaneous operation of compressors in inefficient modes

GD Connect 12 Plus Multi Compressor Controller

The controller provides:

- Control of up to 12 compressors simultaneously

- Intelligent demand forecasting

- Automatic unit on/off depending on load

- Detailed statistics of the entire compressor station operation

Integrated heat recovery system

Turning waste into resource

During air compression, a significant amount of heat is released, which can be effectively used:

- Up to 90% of the energy consumed by the compressor is converted into heat

- Heat recovery for heating production or office premises

- Process water heating for production needs

- Additional savings on heating and water heating

Installation options

- Factory installation – integrated at the compressor production stage

- Retrofit kit – can be installed on existing compressors

- Includes all necessary pipelines, fittings and control system

Benefits of choosing Gardner Denver

Global expertise and local support

Decades of industry experience

Gardner Denver is a recognized leader in compressor equipment manufacturing:

- Decades of experience in development and production

- Continuous innovation and technology improvement

- Compliance with the strictest international quality standards

Comprehensive approach to compressed air

Full range of solutions from one manufacturer:

- Compressors from 2.2 to 500 kW – full power range

- Fixed and variable speed technologies

- Complete line of air treatment equipment

- Oil-free EnviroAire series compressors for critical applications (15-355 kW)

Environmental responsibility

Sustainable production process

Gardner Denver adheres to the principles of environmentally responsible production:

- Use of energy-efficient technologies in own production

- Minimization of waste and emissions

- Rational use of resources

Reducing environmental footprint

ESM and VS series compressors contribute to reducing environmental impact:

- IE3 class energy-efficient motors reduce electricity consumption

- CO2 emission reduction through energy savings

- Heat recovery capability for additional energy consumption reduction

- Equipment durability reduces replacement and disposal needs

Application industries

Versatility for different industries

Manufacturing industry

Gardner Denver compressors are ideal for:

- Automotive manufacturing – powering pneumatic tools and robotic lines

- Mechanical engineering – supporting metal processing technological processes

- Plastics production – control of forming and cooling of products

- Woodworking – powering pneumatic equipment and paint booths

Food industry

Application in the food industry requires special standards:

- Packaging and filling of products

- Transportation of bulk materials

- Equipment cleaning and blowing

- High air quality standards to comply with sanitary norms

Pharmaceutical and chemical industry

Critical requirements for compressed air quality:

- Production of medicinal preparations

- Laboratory equipment

- Technological processes in clean rooms

- Possibility of additional air purification to required standards

Textile industry

Specific needs of textile production:

- Powering weaving machines

- Pneumatic fiber transportation

- Control of fabric tension and quality

Construction and infrastructure

Mobility and reliability for construction sites:

- Powering pneumatic tools

- Sandblasting surface treatment

- Painting large structures

- Temporary compressor stations

Why variable speed compressors are the future

Economic feasibility of VS technology

Fast return on investment

Despite a slightly higher initial cost compared to fixed-speed models, VS series compressors pay off due to:

- Significant reduction in electricity bills (up to 35%)

- Extended service life due to absence of load/unload cycles

- Reduced maintenance costs due to smoother operation

- Typical payback period: 1.5-3 years depending on usage mode

Long-term savings

Calculation for 10 years of operation shows:

- Accumulated electricity savings can exceed the initial equipment cost

- Fewer repairs and component replacements

- Increased overall production efficiency

Adaptation to modern production requirements

Industry 4.0 flexibility

Productions are becoming increasingly flexible and dynamic:

- Rapid change of production tasks requires adaptive compressed air supply

- Integration with other production management systems

- Remote monitoring and control capability

- Data analytics for continuous efficiency improvement

Compliance with environmental standards

Growing energy efficiency requirements:

- Legislative requirements for energy consumption reduction

- Corporate sustainable development goals

- Production certification according to environmental standards

- VS compressors help achieve these goals

Technical support and service

Network of authorized service centers

Professional maintenance

Gardner Denver provides full support throughout the entire life cycle:

- Qualified technicians with official certification

- Regular training of personnel in the latest technologies

- Access to technical documentation and manufacturer support

- Rapid response to challenges

Scheduled technical maintenance

Structured approach to maintenance:

- Clear schedules of routine work

- Use of original spare parts and materials

- Detailed documentation of all performed work

- Recommendations for equipment operation optimization

Personnel training

Programs for operators

Ensuring proper operation:

- Basic training in compressor operation

- Understanding the GD Pilot SE control system

- Safety rules and accident prevention

- Detection of typical faults

Advanced training for technical specialists

Improving the qualifications of maintenance personnel:

- Detailed study of compressor design

- Diagnostics and troubleshooting

- Work with iConn system and remote monitoring

- Optimization of settings for specific operating conditions

Economic analysis and ownership cost

Structure of compressor equipment costs

Initial investment (7% of total costs)

One-time acquisition costs include:

- Cost of the compressor itself

- Delivery and installation

- Connection to power grid and air distribution system

- Initial setup and commissioning

Maintenance costs (10% of total costs)

Regular operating costs:

- Scheduled technical inspections and maintenance

- Replacement of consumables (filters, oil, separators)

- Repair and replacement of worn components

- Equipment downtime cost during maintenance

Energy costs (83% of total costs)

The largest share in ownership cost:

- Electricity consumption throughout the entire service life

- Dependence on operating mode and load

- This is where VS technology provides the greatest savings

- Importance of efficiency at partial load

Savings calculation with VS technology

Example calculation for typical production

Initial data:

- 30 kW compressor

- 6000 hours of operation per year

- Electricity tariff: 0.10 EUR/kWh

- Average load: 70%

Consumption comparison:

- ESM (fixed speed): ~30 kW × 6000 h = 180,000 kWh/year

- VS (variable speed): ~30 kW × 0.65 × 6000 h = 117,000 kWh/year

- Savings: 63,000 kWh/year or 6,300 EUR/year

Payback: With a cost difference of 8,000-10,000 EUR, payback is 1.3-1.6 years

Additional economic benefits

Peak load reduction

VS compressors help reduce electricity costs:

- Smooth start without consumption spikes

- Avoiding penalties for exceeding peak load

- Possibility of using more favorable tariffs

Extended equipment service life

Savings on replacement and repairs:

- Fewer cycles mean less component wear

- Extended intervals between major overhauls

- Higher residual value of equipment upon sale or replacement

Installation and commissioning

Room requirements

Installation room parameters

Optimal conditions for compressor operation:

- Temperature: from +5°C to +40°C

- Ventilation: sufficient fresh air supply for cooling

- Humidity: up to 95% relative humidity (without condensation)

- Air cleanliness: avoid dust and aggressive impurities

Space requirements

Placement planning taking into account:

- Compressor dimensions: 1345 × 880 × 1612 mm

- Additional space for maintenance (minimum 1 m on each side)

- Access for component replacement and transportation

- Space for auxiliary equipment (dryers, receivers)

Connection and startup

Electrical connection

Power supply requirements:

- Corresponding power grid capacity (22-30 kW + reserve)

- Quality grounding for personnel safety

- Protection against overvoltage and short circuit

- Connection according to manufacturer's electrical diagram

Pneumatic connection

Integration into the air distribution system:

- Quality connections to prevent leaks

- Correct pipeline diameter to minimize pressure losses

- Installation of additional equipment (receivers, dryers, filters)

- Condensate drain system

Commissioning

New equipment startup procedure:

- Checking all connections and settings

- Filling the system with lubricant and checking the level

- Test run without load

- Setting operating parameters for specific conditions

- Training operators in basic functions

Frequently asked questions and answers

Model and configuration selection

How to choose between ESM and VS series?

Choose ESM if:

- Your production has stable, constant compressed air demand

- The compressor operates at full load most of the time

- Initial budget is limited

- Maintenance simplicity is a priority

Choose VS if:

- Air demand changes throughout the working day

- The compressor often operates at partial load

- Energy efficiency is a critical factor

- You plan integration with Industry 4.0 systems

What capacity do I need?

Determining required capacity:

- Calculate total consumption of all pneumatic consumers

- Add 20-30% reserve for future expansion and leaks

- Consider equipment simultaneity

- Consider installing a receiver to cover peak loads

Operation and maintenance

How often should the compressor be serviced?

Recommended maintenance intervals:

- Daily: visual inspection, oil level check

- Weekly: condensate check, air filter cleaning

- Every 500 hours: air filter replacement

- Every 2000 hours: oil and oil filter replacement

- Every 4000 hours: separator replacement, detailed inspection

Can the compressor be serviced independently?

Maintenance levels:

- Basic maintenance can be performed by trained enterprise personnel

- Scheduled maintenance is better entrusted to an authorized service center

- Repair and diagnostics require qualified specialists

- To maintain Protect 10 warranty, maintenance in authorized centers is mandatory

Energy efficiency and savings

How much can be saved with VS technology?

Actual savings depend on:

- Your production load profile

- Number of operating hours per year

- Electricity cost in your region

- Typical savings are 20-35% compared to fixed speed

Is it worth installing a heat recovery system?

Heat recovery feasibility:

- With compressor operation more than 4000 hours per year – economically justified

- Greatest efficiency in the cold season

- Ideal for enterprises with hot water or heating needs

- System payback: 2-4 years

Air quality and additional equipment

Do I need an air dryer?

Dryer necessity depends on application:

- Mandatory: for painting, food industry, precision tools

- Recommended: for most production applications

- Possible without it: only for simple pneumatic tools in warm premises

What type of dryer to choose?

Dryer type selection:

- Refrigerant: most popular, economical, dew point +3°C

- Heatless adsorption: for critical applications, dew point up to -40°C

- Heat-regenerated adsorption: energy-efficient for large volumes

Conclusions and recommendations

Why Gardner Denver ESM and VS – the right choice

Gardner Denver ESM and VS series compressors (22-30 kW) represent an optimal combination of:

Reliability:

- In-house production of key components

- Decades of experience and brand reputation

- Extended 10-year Protect 10 warranty

- Minimum number of moving parts

Efficiency:

- Energy savings up to 35% with VS technology

- IE3 class high-efficiency motors

- Optimal operation across all load ranges

- Heat recovery capability

Technological advancement:

- Modern GD Pilot SE control system

- Industry 4.0 integration via iConn

- Predictive maintenance and remote monitoring

- Readiness for future technological requirements

Cost-effectiveness:

- Fast return on investment (1.5-3 years for VS)

- Lowest ownership cost in its class

- Minimum maintenance costs

- Maximum service life

Implementation recommendations

Step 1: Needs analysis

- Determine actual compressed air needs

- Analyze load profile throughout the day/week

- Assess air quality requirements

- Calculate possible savings with VS technology

Step 2: Configuration selection

- Choose a model of appropriate power (VS23, VS26, VS29 or ESM23, ESM26, ESM29)

- Determine the need for additional equipment (dryers, filters, receivers)

- Consider the possibility of installing a heat recovery system

- Plan integration with iConn system for VS models

Step 3: Installation preparation

- Prepare a room with proper ventilation

- Ensure necessary electrical power

- Plan air pipeline routing

- Train personnel in basic operation

Step 4: Commissioning and optimization

- Involve an authorized service center for startup

- Configure operating parameters for your needs

- Activate iConn monitoring system (for VS models)

- Establish a scheduled maintenance plan

Investment in your production future

By choosing Gardner Denver ESM or VS series compressors, you are investing not just in equipment, but in:

- Production continuity thanks to maximum reliability

- Reduction of operating costs through energy efficiency

- Technological flexibility with Industry 4.0 integration capability

- Environmental responsibility through reduced energy consumption and emissions

- Peace of mind and confidence thanks to the best warranty in the industry

Gardner Denver is not just a compressor supplier, but a partner in your business development, providing a reliable source of compressed air for many years of efficient operation.

Main attributes Screw air compressor Gardner Denver ESM23 A34905114B

Reviews about Screw air compressor Gardner Denver ESM23 A34905114B

There are no reviews for this product.

Questions and Answers (FAQ) Screw air compressor Gardner Denver ESM23 A34905114B