Description Screw air compressor Gardner Denver ESM7 RSCGD0701

Screw compressors of the ESM and VS series from Gardner Denver are premium solutions for industrial enterprises that require stable supply of compressed air. These models with power from 7 to 11 kW are available in versions with fixed and variable speed, which allows optimal adaptation to different production needs. Developed with emphasis on durability, energy efficiency and ease of operation, they provide low operating costs and high productivity. The series is known for its innovation, as Gardner Denver constantly improves technologies to achieve maximum flexibility and efficiency. Whether it's the standard line or the high-efficiency e-series – these compressors will become a key element of your compressed air system, guaranteeing quality and savings.

Advantages of the ESM/VS Series for Business

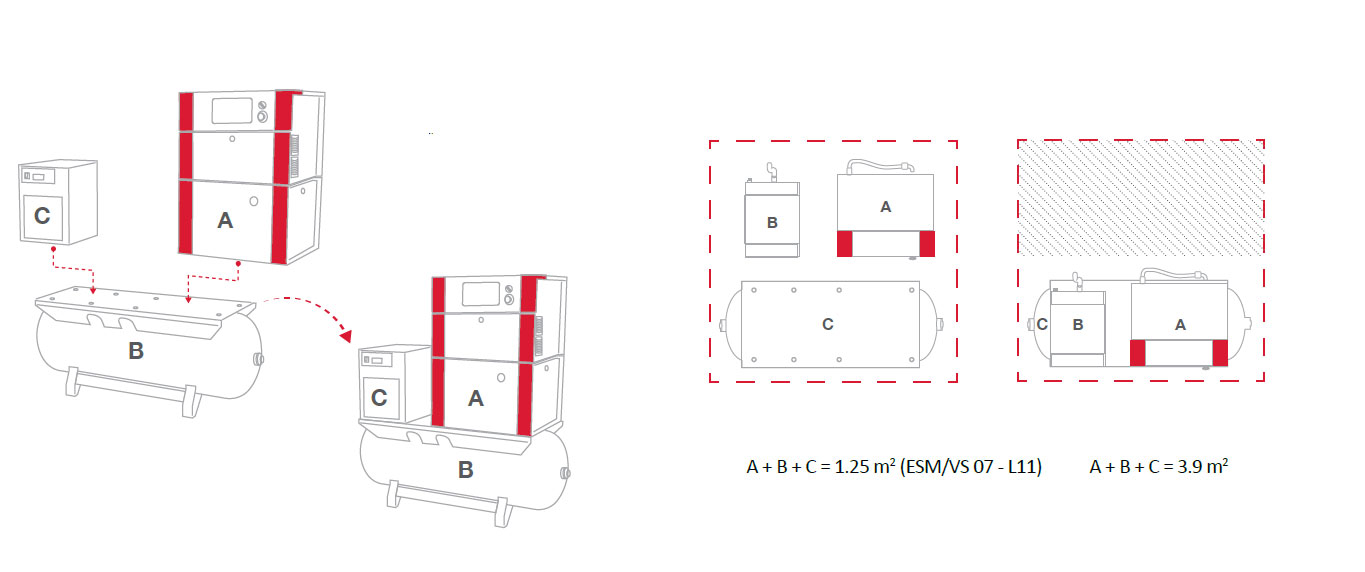

Compressors ESM/VS are not just equipment – this is an investment in production stability. They provide constant supply of high-quality compressed air with minimal costs, which is especially important for manufacturers, processors and operators. Thanks to in-house production of key components, such as the screw block, Gardner Denver controls quality at every stage. This allows achieving low maintenance costs and long service life. The series offers models with pressure from 5 to 13 bar, which makes it universal for different industries: from food industry to machine building. In addition, the compact design with minimal installation area (only 0.4 m² for base models) is ideal for limited spaces, reducing infrastructure costs.

Integration of options, such as receiver and dryer, transforms the compressor into a full-fledged airstation, which simplifies installation and operation. High efficiency is achieved thanks to optimized design, which minimizes energy losses and noise. Gardner Denver focuses on environmental friendliness: compressors operate with low noise and vibration levels, which improves working conditions. Overall, choosing ESM/VS is a step towards cost optimization, as they reduce the total cost of ownership due to energy efficiency and reliability.

Compressors with Fixed Speed: Stability for Constant Loads

Models with fixed speed (Fixed Speed) of the ESM series are ideal for productions with constant demand for compressed air. They provide stable performance without fluctuations, which is critical for processes where interruptions are unacceptable. These compressors are built on the basis of high-efficiency screw blocks, manufactured using modern CNC technologies and laser control, which guarantees accuracy and durability. Fixed rotation speed allows achieving optimal efficiency in full load modes, minimizing energy consumption.

Efficiency and Savings in Daily Operation

One of the key advantages of fixed speed is the simplicity of design, which reduces the risk of breakdowns and simplifies maintenance. Compressors are equipped with IE3 class electric motors that meet international energy efficiency standards, and operate at temperatures up to 46°C. This allows using them in difficult conditions, for example, in hot workshops or regions with high temperature. The automatic belt tension system extends the belt's service life, reduces noise and vibrations, which contributes to comfortable work of operators.

Savings are achieved thanks to low energy losses: the integrated air/oil cooler with bypass quickly warms up the system, preventing condensate and wear. In-house production of dryers with patented heat exchangers provides low pressure drop and compactness. For business, this means reducing electricity costs by 10-15% compared to less efficient analogs, as well as minimizing downtimes thanks to reliable design. Fixed speed is the choice for stable processes, where priority is on reliability and low costs.

Application in Different Industries

Compressors with fixed speed are widely used in the automotive industry, where constant compressed air is needed for painting or assembly. In the food industry, they provide clean air without contaminants, thanks to cleaning options. For small and medium enterprises, ESM is an ideal solution, as it combines affordability with premium quality. Integration with GD Connect systems allows managing multiple compressors, optimizing the overall system efficiency. Overall, these models help business focus on production, not on equipment maintenance.

Compressors with Variable Speed: Flexibility for Variable Needs

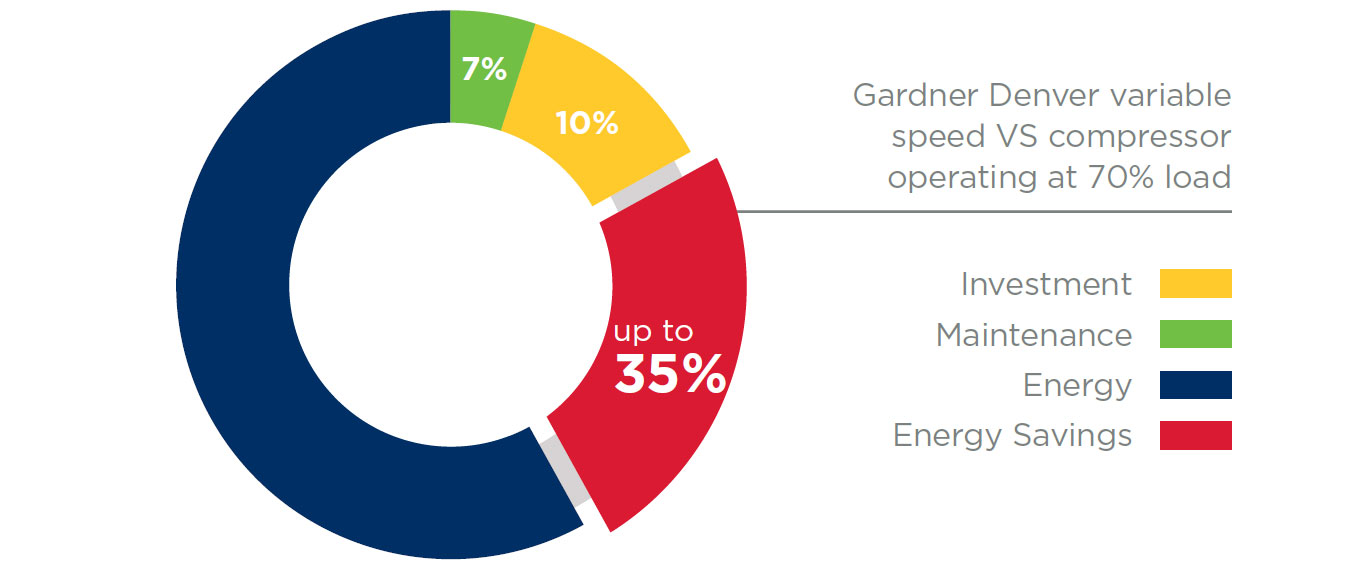

The VS series with variable speed (Variable Speed) is an innovative solution for productions with fluctuating air demand. The speed regulation technology allows the compressor to adapt to real needs, reducing energy consumption up to 35% compared to fixed speed. This is achieved thanks to integration of motor, drive and screw block, which provides a wide regulation range without on/off cycles. VS models effectively cope with peak loads, minimizing wasteful energy costs.

Significant Energy and Resource Savings

Variable speed is the key to energy efficiency: the compressor automatically adjusts rotations to match the current demand, which reduces annual electricity costs. The C-PRO 2.0 or GD Pilot SE controller monitors parameters in real time, allowing easy pressure change with one press. This not only saves money, but also extends equipment service life, as it reduces component wear. In the e-line, manufactured in Germany, efficiency is even higher thanks to the integrated screw block with low rotations, which reduces energy consumption by additional 5-10%.

For business, this means return on investment in 1-2 years due to savings. VS compressors ideally integrate into systems with multiple units, where one VS regulates load, and fixed ones work at full. Low noise level (about 67 dB) and vibrations make them suitable for placement directly in production, without additional isolation. Resource savings also manifest in extended oil change interval – up to 4000 hours, which reduces maintenance costs.

Flexibility in Use and Integration

Variable speed allows VS compressors to adapt to seasonal fluctuations or changes in production, for example, in textile or pharmaceutical industries. Mounting options on receiver or with dryer make them compact airstation, reducing installation area by 55%. The Modbus and RS485 system provides integration with industrial networks, allowing remote monitoring. For enterprises with inconsistent demand, VS is a way to avoid overexpenses, providing precise air supply without surpluses.

Design and Construction: Engineering Excellence

The ESM/VS series stands out with premium design, oriented on reliability and convenience. The key element is the screw block, manufactured by Gardner Denver's own forces using CNC grinding and laser control. This provides a flat specific power curve, which means efficient operation in a wide range of rotations. Compactness is achieved thanks to component integration: oil separator, filter and thermostatic valve reduce the number of hoses, increasing reliability.

In-House Production of Key Components

Gardner Denver screw blocks are the heart of the compressor, developed for maximum efficiency. Rotors are checked by computer system, which guarantees accuracy and minimal losses. Dryers with own heat exchangers provide low pressure drop and compactness. Production in the Center of Excellence in Simmern, Germany, for the e-series emphasizes German quality: from design to assembly, everything is controlled to achieve the best indicators. This not only increases efficiency, but also reduces breakdown risks, providing continuous operation.

Compactness and Simplicity of Installation

With area of only 0.4 m², base models ESM/VS are ideal for limited spaces. Mounting on receiver reduces occupied area by 55%, and removable panels facilitate access to service points. Automatic belt tension minimizes maintenance, and cooling system provides operation at 45°C. For business, this means quick installation and minimal costs for room adaptation, making compressors universal for any conditions.

Control Systems: Intelligence for Efficiency

Compressors are equipped with advanced controllers, such as C-PRO 2.0 for VS and GD Pilot SE for e-series. They provide transparent interface, monitoring pressure, temperature and operating hours. Functions like sequential control up to 8 units, Modbus and micro-SD for logs allow integrating compressors into smart systems. Ergonomic controller placement (top or front) facilitates access, and real-time clock and auto-restart after power failure guarantee continuity.

Functionality for Investment Protection

Controllers protect equipment, monitoring parameters and preventing overloads. For VS models, PID settings adapt performance to demand, saving energy. Multilingualism and 15 error records simplify diagnostics. Integration with web server allows remote control, which is ideal for large enterprises. This not only increases efficiency, but also reduces risks, providing long-term reliability.

Compressed Air Cleaning: Purity for Product Quality

Modern production requires clean air, and Gardner Denver offers a full set for cleaning: from cyclone separators to dryers. Refrigerant dryers provide dew point 3°C, removing condensate, and desiccant – for deep drying. Filters and drains minimize contamination, extending tool service life. Integration with ESM/VS compressors creates energy-efficient system, reducing life cycle costs.

Integration with Cleaning Systems

Options like GD Connect 12 manage multiple compressors, optimizing cleaning. This reduces contamination risks in food or pharmaceutical industries, providing compliance with ISO standards. Effective cleaning not only improves product quality, but also saves resources, reducing reworks and downtimes.

Warranty and Service: Peace for Business

Gardner Denver offers unique Protect 10 warranty – up to 10 years or 44,000 hours on the screw block, free of charge subject to service. This is one of the most generous offers on the market, supported by original spare parts. Service programs provide accurate budgeting, and original lubricants extend change intervals. For business, this means minimal risks and maximum efficiency, with focus on development, not on repairs.

Advantages of Original Spare Parts

Original Gardner Denver parts provide long service life, low losses and high reliability. They are manufactured according to strict standards, reducing downtimes and costs. Service from authorized providers guarantees quality, and Protect 10 warranty – full peace. This is investment protection that pays off with savings and stability.

Main attributes Screw air compressor Gardner Denver ESM7 RSCGD0701

Reviews about Screw air compressor Gardner Denver ESM7 RSCGD0701

There are no reviews for this product.

Questions and Answers (FAQ) Screw air compressor Gardner Denver ESM7 RSCGD0701