Description Screw air compressor Gardner Denver ESM75 A349057014

Compressors Gardner Denver series ESM/VS power 55–75 kW represent themselves advanced solutions for industrial compression air, that combine high reliability, energy efficiency and simplicity exploitation. These systems developed for enterprises, which strive optimize costs on energy, minimize time downtime and provide uninterrupted supply high quality compressed air for production processes.

Gardner Denver constantly improves technologies compressor equipment, introducing innovative solutions, which correspond modern requirements energy efficiency and ecological sustainability. Series ESM/VS is result many years experience company in field production compressor equipment and reflects best engineering practices.

Technical characteristics compressors Gardner Denver ESM/VS 55-75 kW

Main technical parameters

Compressors series ESM/VS 55-75 kW characterized following technical indicators:

Power engine: 55–75 kW

Range working pressure: 5–13 bar

Volumetric flow (FAD): 2,1–14,9 m³/min

Area base: 2,23 m² (on 8% less compared with analogs)

Dew point (with dryer): 3 °C at 7 bar

Compact design compressors provides minimal requirements to area installation, what especially important for enterprises with limited production space. This allows efficiently use area workshop and simplifies integration equipment in existing production lines.

Design features and innovations

Series ESM/VS differs unique integrated design pneumatic element, which includes oil filter and valve regulation oil. Such architecture minimizes quantity external hoses, what increases reliability system and reduces risk leaks. Design and production screw compression element carried out directly Gardner Denver, what guarantees high quality and low operational costs throughout all term service equipment.

All doors compressor are hinged and removable, what provides quick and convenient access to all service points. This significantly simplifies procedures technical maintenance and reduces time downtime equipment during planned works.

Energy efficiency: Key advantage series ESM/VS

Premium pneumatic elements GD6 and GD8

Basis high energy efficiency compressors Gardner Denver ESM/VS is optimized pneumatic elements new generation GD6 and GD8. New pneumatic element GD6 provides increase efficiency up to 5% compared with previous models thanks reduction drop pressure and optimized compact design.

Redesigned semi-integrated pneumatic elements GD6 and GD8 provide general increase efficiency up to 7%. Additionally, these updated pneumatic elements offer higher volumetric flow (FAD) up to 6%, what in combination with improvement efficiency leads to significant reduction general operational costs.

Models "e": Maximum energy efficiency

Models "e" series ESM/VS represent best in its class efficiency with increase up to 6,8% compared with standard models. Thanks introduction new technologies, including automatic valve regulation oil, these models capable save up to €4,500 on annual costs on energy.

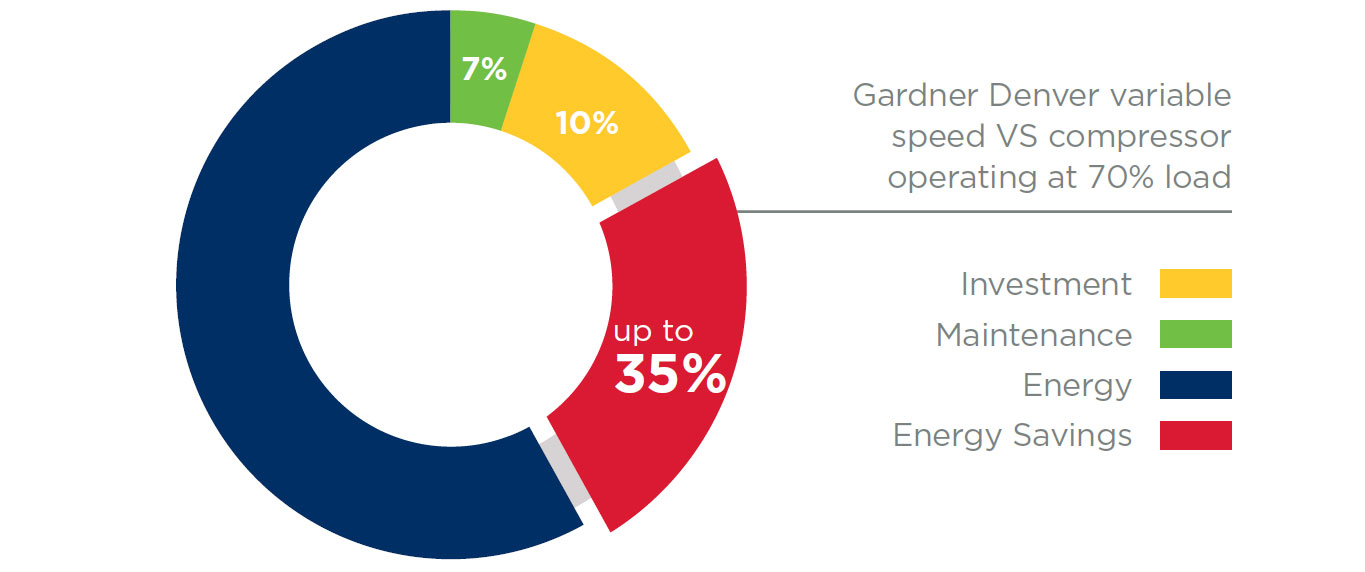

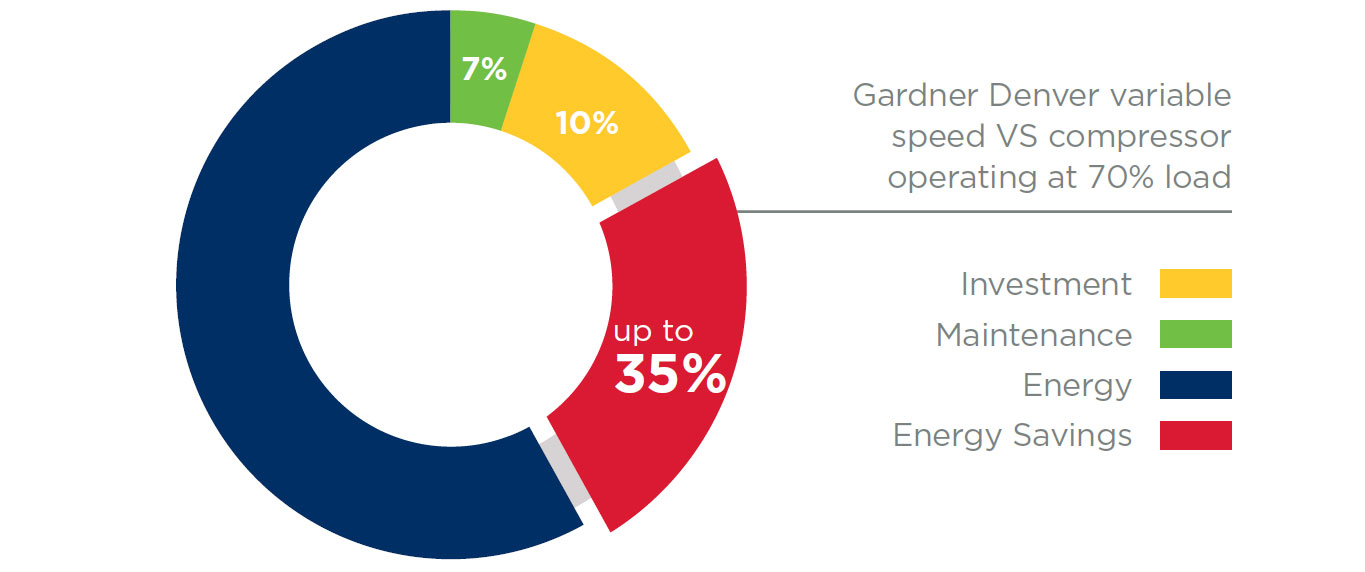

Considering, that energy constitutes largest single cost life cycle compressor, and systems compressed air consume 10% all electricity, that used in industry, saving on energy costs has critical value for general profitability production.

Technology variable speed (VS)

Compressors with technology variable speed (Variable Speed, VS) provide effective and reliable management variable demand on compressed air. This technology allows automatically regulate performance compressor accordingly to current needs production, what significantly reduces annual cost ownership equipment.

Choice model with variable speed recommended as strategic step for optimal correspondence demand on air, especially on enterprises with uneven consumption compressed air throughout shift or production cycle.

Innovative valve regulation oil

Specially developed integrated valve automatic regulation oil, which is standard for models VS, contributes increase efficiency up to 5% depending on conditions exploitation. This innovative component:

- Improves efficiency work on low speeds

- Excludes risk formation condensate in oil system

- Prolongs term service oil

- Optimizes heat exchange in system

High efficient electric engine

All compressors series ESM/VS equipped premium high efficient electric engine, which corresponds most strict standards energy efficiency. Automatic lubrication engine is standard, what prolongs term service bearings and excludes necessity regular maintenance this node.

Intelligent systems control and monitoring

Controller GD Pilot TS SE7: Center management compressor

Controller GD Pilot TS SE7 is heart system management compressor Gardner Denver ESM/VS. It developed for protection investments and provision reliable work by means continuous control working parameters, what has decisive value for reduction operational costs.

Key characteristics GD Pilot TS SE7:

7-inch touch display high resolution provides clear display all information about state compressor and allows intuitively manage all functions systemίσ.

Five main menus with visual display create logical structure interface, which allows operators quickly find needed functions and parameters.

Multilingual interface provides convenience use for personnel different nationalities and simplifies introduction system on international enterprises.

Home page provides instant overview state compressor, including current pressure, performance, temperature and other critical parameters.

Functions programming and settings

Controller GD Pilot offers wide spectrum possibilities for optimization work compressor:

Clock real time allows set time automatic start and stop compressor accordingly to production schedule, what reduces unproductive consumption energy.

Second setting pressure provides possibility program two different values working pressure for different production modes.

Automatic restart after failure power provides quick recovery work compressor after emergency disconnection electricity without intervention operator.

Remote management through programmable inputs allows integrate compressor in general system automation enterprise.

Diagnostics and analytics

Log history faults stores detailed information about all events and deviations in work compressor, what allows conduct in-depth analysis and detect trends, which can indicate on potential problems.

Storage data on SD-card provides possibility archiving different working characteristics for long-term analysis and reporting.

Diagrams trends and graphs provide visual display changes key parameters in time, including:

- Pressure in network

- Speed engine (for VS models)

- Hours under load

- Total time work

- Average volumetric flow

- Weekly average volumetric flow

This function allows precisely tune working parameters for achievement maximum efficiency and detect optimal modes work for specific production conditions.

Integration and possibilities network management

Built-in web-server provides possibility remote access to system management compressor through standard web-browser, what allows control work equipment from any computer or mobile device in network enterprise.

Optional sequencing base load allows coordinate work several compressors for optimization general efficiency system compressed air.

System iConn: Proactive monitoring new generation

Concept Service 4.0

System iConn, which installed on compressors ESM/VS series as standard equipment, represents concept Service 4.0 — intelligent, proactive service monitoring in mode real time. This solution provides deep and actual knowledge about state system compressed air, transforming traditional approach to maintenance equipment.

Prevention downtimes and early detection problems

System iConn allows in advance detect deviations from optimal state installation, what gives possibility initiate countermeasures and avoid expensive failures and downtimes production. Predictive tracking and warnings provide early detection wear components system compressed air, allowing plan replacement parts before occurrence emergency situations.

Maintenance on demand

Revolutionary approach system iConn consists in that intervals technical maintenance more not controlled time. Instead this they based on actual wear individual components and real requirements system. Such system maintenance "on demand" (on-demand maintenance):

- Prolongs term service compressor

- Optimizes costs on maintenance

- Excludes premature replacement components

- Prevents exploitation worn parts

Optimization efficiency and saving

System iConn helps identify potential saving by means constant measurement costs and efficiency work compressor. It contributes maximum performance equipment, what directly reduces energy consumption.

System allows avoid increase operational costs, caused increased drop pressure in filters and separators through delayed maintenance. Timely detection such problems allows maintain optimal efficiency system throughout all term exploitation.

Safety and accessibility data

Confidentiality and protection data: System iConn guarantees confidentiality, integrity data, their authenticity and comprehensive protection from unauthorized access.

24/7 access: Users receive access to operational data in mode real time 24 hours on day, 7 days on week through web-interface or mobile application iConnApp.

Notifications and reports: System automatically sends notifications about alarms and warnings by email, and also generates detailed reports with historical and predictive analysis and trends.

Integration GD Pilot and iConn

Both systems — GD Pilot and iConn — closely integrated, creating comprehensive ecosystem control over all installation. This integration can be compared with modern navigator: GD Pilot is dashboard, which shows speed, pressure and instant warnings, while iConn acts GPS-navigator, which analyzes all conditions exploitation, predicts potential failures and automatically plans optimal routes maintenance.

Ecological and energy saving

Recuperation heat: Transformation costs on saving

About 70% energy, necessary for work screw compressor, transformed into heat during process compression. Usually this heat simply emitted in atmosphere, representing significant losses energy.

Compressors ESM and VS series optionally available with integrated system recuperation heat, which allows:

- Achieve significant saving funds

- Reduce emissions CO2

- Improve general operational costs

- Increase energy efficiency production

Practical application recuperated heat:

Generation hot process water for production processes, which require heating water.

Heating premises in cold period year, what allows reduce costs on gas or electricity for system heating.

Pre-heating water for steam generation, what reduces load on steam boilers and reduces costs fuel.

Examples real saving:

One company, that implemented system recuperation heat on compressors Gardner Denver, reduced annual consumption natural gas on 15%, saving approximately €8,000 on year. Another client achieved annual saving energy in area £23,000 thanks use heat from compressor for heating production premises.

Ecological dryer with refrigerant R513A

New integrated additional dryer, which optionally available for compressors ESM/VS series, uses newest gas technology — refrigerant R513A.

Advantages refrigerant R513A:

Extremely low potential global warming (GWP) makes it truly climate-friendly and corresponds most strict ecological standards.

Compliance future legislation guarantees, that equipment will remain actual and correspond normative requirements in long-term perspective.

Minimized scheme dryer and reworked high efficient heat exchanger reduce risk leakage refrigerant.

Design solutions for reduction ecological impact

Compact design compressors means less use materials at production and smaller carbon footprint during transportation.

Prolonged term service components thanks system predictive maintenance iConn reduces quantity wastes and necessity replacement parts.

High efficient pneumatic elements and engines reduce general consumption electricity, what especially important in context global efforts on decarbonization industry.

Processing and quality compressed air

Importance quality air for production

Modern production systems and processes require increasingly higher levels quality compressed air. Unwanted substances in compressed air can originate as from surrounding air, that sucked (dirt, dust, water, micro-contaminants), so and generated itself process compression (for example, oil).

Moisture and contaminants can:

- Damage production equipment and tools

- Reduce efficiency pneumatic systems

- Lead to defect products

- Increase operational costs

- Cause corrosion pipelines and equipment

Proper system processing air allows avoid moisture and contaminants, providing supply compressed air exact quality, defined application or process.

Integrated dryer: Technical characteristics

Compressors ESM/VS series optionally available with integrated additional irreversible refrigeration dryer, developed specially for work 1:1 with compressor.

Dew point: 3 °C at working pressure 7 bar, temperature on input 35°C and temperature surrounding environment 25°C (measurement accordingly to ISO 7183).

Such dew point provides reliable protection from condensation moisture in pipelines and equipment in most industrial applications.

Monitoring quality air

Controller GD Pilot provides integrated management dryer, constantly tracking its performance. Thanks connection to network iConn, users can:

- Remotely track main parameters dryer

- Control dew point in mode real time

- Receive notifications about deviations from normal parameters

- Analyze historical data performance

Comprehensive solutions processing air

Gardner Denver offers full spectrum products for processing and management air, what allows create comprehensive system, optimized for specific needs production:

Water cyclone separators for primary removal condensate.

Filters compressed air different classes cleaning for removal solid particles, oil and other contaminants.

Systems drainage condensate for automatic removal accumulated moisture.

Different types dryers: refrigeration, adsorption without heating, adsorption with regeneration heat, sublimation, dryers with heater and blower — for different requirements to dew point.

Generators nitrogen for applications, which require inert atmosphere.

Coordination all components system, including processing air, allows precisely evaluate operational costs and reduce carbon footprint production.

Reliability and maintenance

Simplified access for maintenance

Thanks updated design compressors ESM/VS, technical maintenance became significantly simpler. All doors are hinged and removable, what optimizes accessibility to all service points. This allows:

- Reduce time on planned maintenance

- Decrease costs on involvement service personnel

- Perform part operations forces own personnel enterprise

- Minimize time downtime equipment

New thin separator

Innovative thin separator has only one integrated seal, what significantly simplifies technical maintenance. Unlike previous designs, it not requires replacement sealing rings, what saves time and reduces cost maintenance.

Automatic lubrication engine

Automatic lubrication engine is standard for all models series ESM/VS. This function:

- Prolongs term service bearings

- Excludes necessity regular manual lubrication

- Reduces risk premature failure through insufficient lubrication

- Decreases costs on maintenance

Own production critical components

Design and production screw compression element remain internal affair Gardner Denver. This provides:

- Full control over quality key components

- Low operational costs throughout all term service

- Availability original spare parts

- Long-term support and service

Warranty Protect 10: Confidence in reliability

Gardner Denver offers one of most advantageous warranties in branch compressor equipment — program Protect 10. This warranty is absolutely free for owner compressor.

Conditions warranty Protect 10:

Pneumatic elements covered warranty up to 44,000 hours or 10 years — depending on that, what comes earlier. This testifies about confidence manufacturer in reliability and durability most important components compressor.

At average mode work 8 hours on day, 250 days on year, 44,000 hours correspond approximately 22 years exploitation, what significantly exceeds standard warranty terms in branch.

Strategic approach to implementation system compressed air

Analysis demand and planning

For achievement maximum efficiency from compressor Gardner Denver ESM/VS, basis for any decision must be precise analysis existing systems, calculation current and future demand on compressed air.

Important consider:

- Peak and average needs in compressed air

- Seasonal fluctuations demand

- Plans expansion production

- Necessity reservation capacities

Choice optimal configuration

Standard model or "e": For stable production with constant load may be sufficient standard models, while for maximum energy efficiency recommended models "e".

Fixed or variable speed: Choice technology VS recommended for productions with uneven demand on compressed air, what allows achieve maximum saving energy.

Integration dryer: Decision about installation integrated dryer depends from requirements to quality air specific applications.

System recuperation heat: Economic feasibility depends from possibility use heat on enterprise and duration heating season.

Comprehensive approach to system

Important not go on compromise with full system compressed air. If all components system, including production, processing, distribution and use air, coordinated, this allows:

- Precisely evaluate operational costs and costs on energy

- Reduce carbon footprint production

- Maximize efficiency investments

- Provide stable quality compressed air

Avoidance leaks and optimization distribution network

Necessary regularly check system on presence leaks and eliminate them. Even small leaks can lead to significant losses energy and necessity increase power compressor equipment.

Also important eliminate work compressor without load (off-load running), since even in mode idle compressor consumes up to 30-40% nominal power.

Conclusion: Investment in future production

Compressors series Gardner Denver ESM/VS (55–75 kW) represent themselves not simply purchase equipment, but strategic investment, which provides low operational costs and high quality air thanks combination advanced technologies.

Key advantages for your business

Economic efficiency: Thanks optimized pneumatic elements GD6/GD8, models "e" with increased efficiency up to 6,8% and technology variable speed, these compressors provide saving up to €4,500 on year only on energy consumption. Additionally, system recuperation heat can save from €8,000 to £23,000 annual costs on heating and hot water supply.

Maximum reliability: Unique integrated design pneumatic element with minimal quantity external hoses, own production critical components and warranty Protect 10 (44,000 hours or 10 years) provide uninterrupted work throughout decades.

Intelligent management: Integration controller GD Pilot TS SE7 with 7-inch touch display and system proactive monitoring iConn creates ecosystem Industry 4.0, which transforms approach to maintenance — from planning by time to maintenance by actual state components.

Ecological responsibility: Use refrigerant R513A with extremely low GWP, possibility recuperation up to 70% energy in form heat and high efficient components make these compressors corresponding most strict ecological standards and future legislation.

Compactness and convenience maintenance: Area base only 2,23 m² (on 8% less competitors), hinged and removable doors for quick access, new thin separator with one seal and automatic lubrication engine significantly simplify exploitation and maintenance.

For whom intended compressors ESM/VS 55-75 kW

These compressors are ideal solution for:

Production enterprises with constant or variable demand on compressed air in range 2,1–14,9 m³/min at pressure 5–13 bar.

Companies, that strive optimize energy costs and reduce carbon footprint their activities.

Enterprises with limited space for installation compressor equipment.

Organizations, which require high quality compressed air for sensitive production processes.

Businesses, that implement concept Industry 4.0 and strive to digitalization production processes.

Long-term value investment

Compressors Gardner Denver ESM/VS — this solution with focus on total cost ownership (Total Cost of Ownership), and not only on initial price purchase. Considering, that energy constitutes 75-80% cost life cycle compressor, investment in high efficient equipment pays off throughout 2-4 years and continues bring saving throughout decades exploitation.

System predictive maintenance iConn not only prevents expensive downtimes (cost which can constitute thousands euro per hour), but and optimizes schedule technical maintenance, excluding as premature replacement components, so and exploitation worn parts.

Support and service

Gardner Denver has branched network service centers and qualified engineers, what provides:

- Quick reaction on requests about technical support

- Availability original spare parts

- Regular training personnel clients

- Consultations regarding optimization work system compressed air

- Remote diagnostics through system iConn

Future readiness

Choosing compressor Gardner Denver ESM/VS, you invest in technology, which ready to future challenges:

Compliance ecological norms: Use refrigerant R513A and possibility deep recuperation heat provide compliance future ecological standards.

Digital readiness: Integration with systems Industry 4.0 through iConn and web-server GD Pilot allows easily integrate compressor in general system management enterprise.

Scalability: Possibility coordination work several compressors through sequencing base load provides flexibility at expansion production.

Energy security: High efficient technologies protect from growth cost energy carriers in future.

Compressors Gardner Denver series ESM/VS (55–75 kW) — this combination German engineering perfection, advanced technologies energy saving and intelligent systems management, created for enterprises, which value reliability, efficiency and ready invest in long-term competitiveness their production.

Main attributes Screw air compressor Gardner Denver ESM75 A349057014

Reviews about Screw air compressor Gardner Denver ESM75 A349057014

There are no reviews for this product.

Questions and Answers (FAQ) Screw air compressor Gardner Denver ESM75 A349057014