Description Single Stage Variable Speed Water Injected Oil-Free Air Compressor Gardner Denver EnviroAire 15 A35004105W

Gardner Denver EnviroAire presents innovative solution in sphere oil-free compression air – single-stage compressors with technology injection water and adjustable speed. This revolutionary series compressors power from 15 to 37 kW sets new standard efficiency, environmental-friendliness and reliability for enterprises, which need absolutely clean compressed air.

In world, where quality products and energy-efficiency become critically important factors competitiveness, compressors EnviroAire VS (Variable Speed) offer unique combination 100% oil-free air, minimal energy-consumption and simplicity maintenance. This technology ideally suits for food industry, pharmaceuticals, production beverages, electronics and other branches, where even smallest contamination oil can lead to catastrophic consequences.

Unique Technology Injection Water: Principle Work and Advantages

How Works Water-injection Compressor EnviroAire

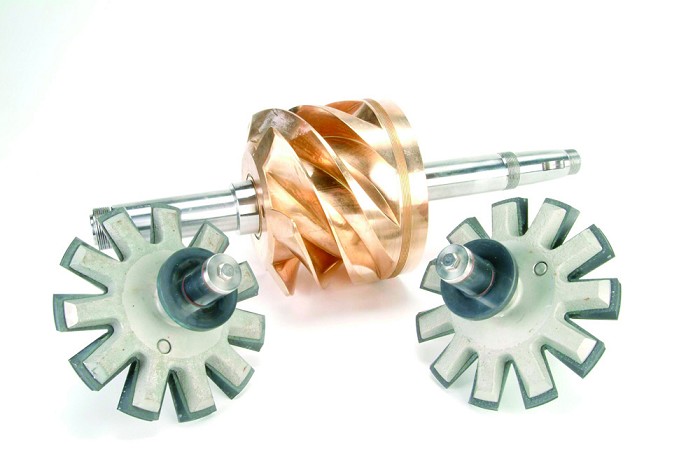

Single-stage oil-free compressors Gardner Denver EnviroAire use water high quality as universal working agent, that performs immediately three critically important functions in process compression:

1. Lubrication without oil: Water creates ideal lubricating layer between rotors and body compressor, completely excluding necessity use oil in chamber compression. This guarantees, that compressed air remains absolutely clean on 100%, without any traces oil contamination.

2. Effective cooling: Injection water directly in chamber compression provides exceptionally effective removal heat, that forms during compression. Thanks high heat-capacity water, working temperatures compressor EnviroAire remain constantly low, that significantly increases efficiency process compression and prolongs term service components.

3. Sealing: Water creates reliable sealing between rotors, minimizing internal leaks air and maximizing volumetric efficiency compressor. This provides optimal productivity at minimal energy-consumption.

Advantages Water-injection Technology

Absolute purity air: Completely oil-free design guarantees, that in compressed air absent even traces oil contamination. This critically important for applications, where contact with product must correspond highest standards quality and safety.

Maximum energy-efficiency: Low working temperatures, achieved thanks water cooling, mean more effective thermodynamic process compression. Single-stage design with direct drive minimizes mechanical losses, providing best indicator specific power in its class.

Environmental purity: Absence oil means absence necessity utilization spent lubricant and contaminated oil parts. This not only saves time and costs on maintenance, but also significantly reduces environmental impact your production.

Simplicity design: EnviroAire has significantly less moving parts compared with traditional oil or dry oil-free compressors. Direct drive, single-stage element compression and absence system oil management provide highest reliability and minimal requirements to maintenance.

Technology Variable Speed (VS): Intelligent Adaptation to Needs Production

Principle Work System Variable Speed

Compressors EnviroAire VS equipped advanced system regulation speed rotation engine, which automatically adapts productivity compressor to real demand on compressed air in your system. Instead work on constant speed with cycles load/unload, compressor with variable speed smoothly changes revolutions engine, providing exactly such quantity air, which necessary in concrete moment time.

Advantages Technology Variable Speed

Significant saving energy: Biggest advantage systems VSD consists in dramatic reduction consumption electricity. In real production conditions demand on compressed air rarely remains constant – it fluctuates during working day, week and seasons. Compressor with fixed speed forced work on full power even at reduced demand, spending energy in vain. EnviroAire VS reduces costs on electricity on 20-35% compared with traditional systems, adapting to actual consumption.

Stable pressure in network: System variable speed supports constant set pressure in pneumatic network with exceptional accuracy. This means, that you can work with lower set pressure, that additionally reduces energy-consumption (each 1 bar reduction pressure saves approximately 7% energy), at that guaranteeing sufficient pressure for all consumers.

Smooth start and stop: Unlike compressors with direct start, which create significant current loads on electrical network at start, EnviroAire VS provides soft smooth start, that reduces peak loads and prolongs term service electrical equipment.

Wide range regulation: Compressors EnviroAire VS can effectively work in wide range productivity, from minimal to maximal flow, providing optimal efficiency at any level load.

Reduction mechanical wear: Smooth work without sharp starts and stops, as well as lower working temperatures thanks water cooling significantly reduce mechanical wear components compressor, prolonging intervals between maintenances and general term service equipment.

Technical Characteristics EnviroAire VS: Power and Productivity

Range Powers and Productivity

Series EnviroAire VS covers wide range powers, that allows select optimal solution for enterprises different scale:

Power engine: from 15 to 37 kW

Volumetric flow air: from 0.32 to 5.86 m³/min (from 320 to 5860 liters per minute)

Working pressure: from 5 to 10 bar (adjustable)

Such flexibility allows apply compressors EnviroAire VS as for small production lines, so and for complex industrial systems with possibility parallel work several compressors.

Design Features

Direct drive: Engine directly connected with screw element without gearbox or belt transmission. This minimizes mechanical losses and increases general efficiency system on 3-5% compared with compressors with belt drive.

Single-stage element compression: Specially developed screw block with optimized profile rotors provides effective compression for one stage to pressure 10 bar. This simplifies design and increases reliability compared with two-stage systems.

System water-preparation and circulation: Integrated system purification and cooling water supports optimal quality and temperature working fluid. Water circulates in closed circuit, minimizing consumption and providing stable conditions work.

Water separator: High-efficient system separation removes water from compressed air at exit from compressor, providing point dew under pressure at level +3°C without additional dryer (for base configuration).

Compact design: Thanks simplicity design and integration all components in single body, EnviroAire VS occupies minimal area – on 30-40% less, than equivalent systems traditional design.

Spheres Application: Where EnviroAire VS Demonstrates Best Results

Food Industry and Production Beverages

In food industry compressed air often has direct contact with product – at bottling beverages, packaging products, cleaning and sorting raw materials. Even microscopic drops oil can lead to spoilage products, change taste, smell and appearance, as well as create risks for health consumers.

Concrete applications:

- Bottling beer, wine and non-alcoholic beverages

- Pneumatic transportation flour, sugar and other bulk ingredients

- Aeration dough and confectionery masses

- Packaging products in modified atmosphere

- Cleaning bottles and containers compressed air

- Control pneumatic valves and drives on lines bottling

EnviroAire VS guarantees 100% oil-free air, that provides compliance strictest standards food safety (ISO 8573-1 Class 0) and requirements HACCP, FDA, BRC.

Pharmaceutical Industry

Pharmaceutical production presents highest requirements to purity compressed air. Compressors EnviroAire VS ideally suit for:

- Production tablets and capsules

- Bottling liquid medicinal forms

- Fermentation and biotechnological processes

- Transportation active pharmaceutical ingredients (API)

- Control automated systems dosing

- Cleaning equipment and premises

Absence oil in air excludes risk cross-contamination, that is critical for validation pharmaceutical processes and compliance standards GMP (Good Manufacturing Practice).

Electronic Industry

Production electronics, microchips and semiconductors requires cleanest air, since even submicron particles can lead to defect expensive products.

Applications EnviroAire VS:

- Cleaning boards and components

- Cooling equipment

- Pneumatic control precision positioners

- Creation air curtains in clean rooms

- Transportation components in production machines

Oil-free air from EnviroAire prevents formation oil film on sensitive surfaces, that could disrupt processes soldering, gluing and application coatings.

Dentistry and Medicine

Medical compressed air used for breathing patients and in direct contact with body human, therefore requirements to its purity are absolute.

Medical applications:

- Dental units and instruments

- Apparatus artificial lung ventilation

- Surgical instruments with pneumatic drive

- Laboratory equipment

- Systems remote transportation samples

EnviroAire VS provides air medical quality according to standards ISO 7396-1, excluding risk inhalation oil aerosols patients.

Textile Industry

In textile production compressed air used for:

- Work pneumatic weaving looms

- Cleaning fibers and yarn

- Transportation textile materials

- Cooling equipment

Oily air leaves stains on fabrics, that leads to defect. EnviroAire VS guarantees impeccable purity products.

Painting and Application Coatings

At pneumatic spraying paints, varnishes and coatings oil from compressed air can get on processed surface, causing defects (craters, delamination, change color). Oil-free compressors EnviroAire VS guarantee ideal quality painting.

Comparison with Other Technologies Oil-free Compression

EnviroAire VS against Dry Oil-free Compressors

Dry oil-free compressors (such as EnviroAire T/TVS) use special coatings rotors and work without any lubrication in chamber compression. Main differences:

Advantages EnviroAire VS (water-injection):

- Significantly lower working temperatures (60-70°C against 180-200°C in dry compressors)

- Simpler design with less quantity moving parts

- Lower cost acquisition and maintenance

- More compact sizes

- Lower level noise thanks damping effect water

Advantages dry compressors EnviroAire T/TVS:

- Higher productivity (up to 355 kW)

- Possibility work at extremely low temperatures environment

- Absence system water-preparation

- Better point dew under pressure at exit

Conclusion: For small and medium systems (up to 37 kW) water-injection EnviroAire VS offer optimal ratio price, efficiency and simplicity. For large industrial systems better suit dry compressors EnviroAire T/TVS.

EnviroAire VS against Oil Compressors with Filtration

Some enterprises use ordinary oil compressors with multi-stage system filtration for obtaining oil-free air. However this approach has significant drawbacks:

Problems oil compressors with filters:

- Impossibility guarantee 100% absence oil (possible only certification Class 1, but not Class 0)

- High costs on regular replacement filtering elements

- Significant pressure drop on filters (0.5-1.5 bar), that increases energy-consumption

- Risk breakthrough oil at damage or saturation filters

- Necessity utilization spent oil and contaminated filters

- Constant monitoring state filters

Advantages EnviroAire VS:

- Absolute guarantee absence oil at level design (certificate ISO 8573-1 Class 0)

- Minimal requirements to filtration (needed only moisture separator)

- Lower pressure drop – saving energy

- Absence risk emergency contamination

- Environmental-friendliness – no contaminated wastes

Economic Efficiency: Analysis Cost Life Cycle

Structure Costs on Operation Compressor

Studies show, that cost acquisition compressor constitutes only about 10-15% from total costs for 5-10 years operation. Main costs distributed so:

- Electricity: 70-85% total costs

- Maintenance and spare parts: 10-15%

- Cost downtimes: 5-10%

- Primary investments: 10-15%

Exactly therefore EnviroAire VS with technology variable speed provides lowest cost ownership, focusing on reduction largest article costs – consumption electricity.

Calculation Saving from Use Technology VS

Example: Enterprise works 6000 hours per year with compressor 30 kW. Average load – 70% from nominal productivity. Cost electricity – 4 UAH/kW·h.

Compressor with fixed speed:

- Consumption at 70% load: ~85% from nominal power = 25.5 kW

- Annual consumption: 25.5 kW × 6000 h = 153,000 kW·h

- Annual costs on energy: 153,000 × 4 UAH = 612,000 UAH

EnviroAire VS (variable speed):

- Consumption at 70% load: ~72% from nominal power = 21.6 kW

- Annual consumption: 21.6 kW × 6000 h = 129,600 kW·h

- Annual costs on energy: 129,600 × 4 UAH = 518,400 UAH

Saving: 612,000 - 518,400 = 93,600 UAH per year (15.3%)

At more variable schedule load saving can reach 25-35%.

Reduction Costs on Maintenance

Comparison with oil compressors:

- Absence costs on compressor oil: saving ~15,000-25,000 UAH/year

- Absence oil filters and separators: saving ~8,000-12,000 UAH/year

- Absence costs on utilization oil: saving ~3,000-5,000 UAH/year

- Smaller requirements to air filtration: saving ~10,000-15,000 UAH/year on replacement filters

Total saving on maintenance: 36,000-57,000 UAH/year

Prevention Costs from Contamination Products

Hardest evaluate, but potentially most significant is saving from prevention contamination products:

- Absence defect through oil contamination

- Absence risk recall products

- Protection reputation brand

- Absence fines from regulatory organs

- Absence downtimes through contamination equipment

For food and pharmaceutical enterprises this article can constitute hundreds thousands or even millions UAH potential losses, which manage avoid.

Integration in Production Systems

Autonomous Work

EnviroAire VS can work as standalone compressor for provision compressed air separate line or small enterprise. Thanks built-in controller and system protection, compressor automatically supports set pressure and reacts on changes consumption.

Work in Composition Multi-compressor Station

For large enterprises with high and variable consumption compressed air optimal is use several compressors in cascade:

Typical configuration:

- 1-2 compressors EnviroAire VS with variable speed for coverage base load and adaptation to changes

- 1-2 compressors with fixed speed for coverage peak loads

Advantages such scheme:

- Maximum energy-efficiency at any level consumption

- High reliability (redundancy)

- Possibility planned maintenance without stop production

Integration with Systems Management

Controller GD Pilot: Built-in controller provides:

- Precise maintenance set pressure

- Monitoring parameters work in real time

- Protection from emergency situations

- Diagnostics and indication faults

- Planning maintenance by operating time

GD Connect 12 Plus: System centralized management compressor station:

- Automatic sequencing up to 12 compressors

- Optimization work for minimal energy-consumption

- Provides up to 35% additional saving energy

- Web-interface for remote monitoring

iConn (Industry 4.0): Intelligent system for integration in concept smart production:

- Cloud monitoring and analytics

- Predictive maintenance on basis artificial intelligence

- Remote diagnostics and support

- Analysis efficiency and recommendations on optimization

- Free for new compressors EnviroAire

Reliability and Maintenance

Design Reliability

EnviroAire VS developed for uninterrupted work in most difficult industrial conditions:

Simplified design: Minimal quantity moving parts reduces probability failures. Absence gearboxes, belt transmissions, systems oil management makes compressor extremely reliable.

Low working temperatures: Water cooling supports temperatures in chamber compression at level 60-70°C, that significantly lower, than in oil (80-95°C) and dry oil-free (180-200°C) compressors. This reduces thermal loads on materials and increases durability.

Quality materials: Screw rotors made from high-strength corrosion-resistant steel. Body element compression – from aluminum alloy with anti-corrosion coating.

Effective air filtration: High-quality air filter protects element compression from abrasive particles, prolonging term its service.

Program Maintenance PureCare

Gardner Denver offers specialized programs maintenance PureCare for oil-free compressors:

Level 1 – Base maintenance:

- Regular inspections according to schedule

- Replacement air filters

- Check system water-preparation

- Control parameters work

Level 2 – Extended maintenance:

- All from Level 1

- Preventive replacement consumables

- Optimization settings for maximum efficiency

- Priority technical support

Level 3 – Full service:

- All from Level 2

- Extended warranty on equipment

- Guaranteed time response on appeals

- Planned capital repairs

- Free substitution on period repair

Advantages PureCare:

- Performance works trained at factory technicians Gardner Denver

- Use original spare parts

- Predictable costs on maintenance (fixed annual fee)

- Maximization time failure-free work

- Preservation warranty manufacturer

Typical Schedule Maintenance

Weekly / as necessary:

- Check indicators and warnings on panel management

- Removal condensate from drainage system (at absence automatic drainage)

Every 500 working hours / 3 months:

- Cleaning or replacement air filter

- Check state water filter

- Control quality water in system cooling

- Check tightness connections

Every 2000 working hours / 12 months:

- Replacement air filter

- Replacement water filter

- Check and cleaning heat exchangers

- Control tightening bolt connections

- Check electrical connections

- Calibration sensors pressure and temperature

Every 8000 working hours / 4-5 years:

- Capital inspection screw element

- Replacement bearings (as necessary)

- Full check electronics and controller

- Update software

Thanks simplicity design, cost and complexity maintenance EnviroAire VS on 30-40% lower compared with equivalent oil compressors.

Environmental Advantages

Minimization Wastes

Absence oil wastes: Unlike oil compressors, EnviroAire VS not generates spent oil, which requires special utilization as dangerous waste. For compressor 30 kW, that works 6000 h/year, this saving about 150-200 liters oil annually.

Absence contaminated filters: Oil compressors use oil filters, separators and numerous air filters fine purification, all of which soaked oil and require special utilization. EnviroAire VS uses only simple air filters, which can be utilized as ordinary industrial waste.

Reduction Emissions CO₂

Direct reduction through energy-efficiency: Saving electricity on 15-35% thanks technology variable speed directly translates into reduction emissions CO₂. For compressor 30 kW with saving 23,400 kW·h/year this equivalent reduction emissions CO₂ approximately on 12-15 tons annually (depending on structure electrogeneration).

Absence leaks refrigerants: EnviroAire VS uses water cooling, therefore not requires systems with refrigerants, which can have high potential global warming (GWP).

Possibility Heat Recovery

Although EnviroAire VS thanks effective water cooling generates less heat, than oil compressors, even this heat can be usefully used:

Heating process water: Heat, that removed from compressor through system water cooling, can be used for preliminary heating process water, that additionally reduces energy-consumption enterprise.

Heating premises: In cold period year heat from compressor installation can be used for heating production or administrative premises.

Economic effect: Recovery up to 70-80% heat can provide additional saving energy resources and reduce term payback compressor still on 10-15%.

Support Standards Quality and Certification

ISO 8573-1 Class 0 (Quality Air)

EnviroAire VS guarantees highest level quality compressed air according to international standard ISO 8573-1:

Class 0 for content oil: Complete absence oil in compressed air, confirmed independent certification. This highest possible level purity, which cannot be achieved by any oil compressor, even with multi-stage filtration.

Meaning for production:

- Compliance strictest industry standards

- Possibility use in critical applications

- Legal compliance requirements regulators

- Minimization risks for quality products

Industry Certifications

FDA (Food and Drug Administration): EnviroAire VS complies requirements FDA for use in food and pharmaceutical industry USA.

HACCP (Hazard Analysis and Critical Control Points): System can be integrated in programs HACCP as critical control point for provision safety food products.

GMP (Good Manufacturing Practice): Compliance requirements good manufacturing practice for pharmaceutical industry.

ISO 22000 (Systems management safety food products): Oil-free air EnviroAire VS supports compliance this standard.

Comparison EnviroAire VS with Flagship Model Ultima

Gardner Denver offers two key lines oil-free compressors with different technological approaches:

Ultima (75-160 kW) – Two-stage Dry Compressors with Two Engines

Technology: Revolutionary design with two synchronous engines with permanent magnets, each of which independently drives separate stage compression (low and high pressure). Absence gearbox ("digital gearbox").

Advantages:

- Highest energy-efficiency in class (up to 13% saving against standard)

- Smallest dimensions (up to 37% more compact two-stage analogs)

- Lowest level noise (max. 69 dB(A))

- Recovery up to 98% heat

- Optimal productivity at any load

Applications: Large industrial objects with high consumption air, where critical maximum energy-efficiency.

EnviroAire VS (15-37 kW) – Single-stage Water-injection Compressors

Technology: Water injection for lubrication, cooling and sealing. Direct drive, maximally simplified design.

Advantages:

- Lowest cost acquisition in segment oil-free

- Maximum simplicity and reliability

- Minimal costs on maintenance

- Smallest dimensions in its class power

- Environmental-friendliness (absence oil wastes)

Applications: Small and medium enterprises, separate production lines, where needed guaranteed clean air at optimal investments.

Conclusion: Both lines provide 100% oil-free air Class 0, but EnviroAire VS optimal for small and medium segment thanks ratio price/quality, and Ultima – for large energy-intensive installations, where investments in maximum efficiency pay off in 2-3 years.

Installation and Commissioning

Requirements to Placement

Area: Thanks compact design, EnviroAire VS requires minimal area. Typical compressor 30 kW occupies about 1.2-1.5 m² floor area.

Ventilation: Premises must have sufficient ventilation for removal heat. Recommended air exchange: 0.28 m³/s per each 10 kW power compressor.

Temperature environment: Optimal range +5°C to +40°C. Possibility work to +46°C at reduced productivity.

Foundation: Thanks low level vibrations, not needed special foundation. Sufficient flat concrete floor.

Access for maintenance: Necessary provide minimum 1 meter free space around compressor for maintenance and circulation air.

Connection Communications

Power supply:

- 3-phase network 380-400V, 50Hz

- Protection according to requirements manufacturer

- Recommended use RCD and differential automatic

Cooling water (for water-cooled models):

- Quality water according to specification manufacturer

- Temperature at inlet: +5°C to +30°C

- Pressure: 2-4 bar

- Flow: according to technical documentation

Pneumatic network:

- Pipelines sufficient diameter for minimization losses pressure

- Recommended installation shut-off valves at exit

- Drainage condensate in lowest points system

Commissioning Works

Recommended conducting commissioning certified specialists Gardner Denver:

- Check correctness connection all communications

- Setting parameters controller under concrete conditions

- Check work all systems protection

- Test start and exit to working mode

- Training personnel basics operation and maintenance

- Registration warranty documentation

System Expansion and Modernization

Stage-by-stage Increase Power

EnviroAire VS ideally suits for stage development system compressed air:

Initial stage: Installation one compressor for coverage base needs enterprise.

Stage expansion: At growth consumption added second compressor, which works parallel with first. System automatically distributes load.

Further expansion: Possible addition additional compressors and integration system centralized management GD Connect for optimization work all station.

Advantages such approach:

- Minimal initial investments

- Flexibility in response on changes production

- Redundancy and high reliability

- Possibility planned maintenance without stop production

Modernization Existing Systems

EnviroAire VS can be integrated in existing compressor stations:

Replacement outdated compressors: Old energy-intensive compressors replaced modern EnviroAire VS with significant saving energy.

Addition systems on base oil compressors: For critical processes, that require guaranteed oil-free air, added separate circuit on base EnviroAire VS.

Optimization mixed systems: Use EnviroAire VS with variable speed as base compressor, and existing compressors – for coverage peak loads.

Technical Support and Service

Global Network Service Gardner Denver

Gardner Denver has branched network service centers worldwide, that guarantees:

- Availability original spare parts

- Qualified specialists near your object

- Fast response on appeals (24/7 hot line)

- Expert support at setting and optimization

Remote Diagnostics through iConn

System iConn allows specialists Gardner Denver:

- Remotely monitor parameters work compressor

- Detect potential problems at early stages

- Conduct diagnostics without departure to object

- Provide recommendations on optimization work

- Plan maintenance on basis real state equipment

This significantly reduces time downtime and increases general efficiency system.

Training Personnel

Gardner Denver offers programs training for personnel customer:

Base course:

- Principles work compressor

- Daily operation

- Monitoring parameters

- Base maintenance

Extended course:

- Deep understanding system

- Diagnostics faults

- Optimization settings

- Planning maintenance

Trained personnel – key to maximum efficiency and reliability system compressed air.

Conclusion: Why EnviroAire VS – Optimal Choice

Single-stage oil-free compressors Gardner Denver EnviroAire with technology injection water and variable speed represent optimal combination purity air, energy-efficiency, reliability and economic feasibility for small and medium enterprises.

Key advantages EnviroAire VS:

✓ 100% oil-free air – certification ISO 8573-1 Class 0, absolute guarantee purity

✓ High energy-efficiency – saving 15-35% electricity thanks technology VSD

✓ Minimal costs on maintenance – simple design, absence oil management

✓ Environmental-friendliness – without oil wastes, lower emissions CO₂

✓ Compactness – minimal dimensions and weight in its class

✓ Reliability – less moving parts, low working temperatures

✓ Low level noise – comfortable working conditions

✓ Flexibility – adaptation to variable needs production

✓ Compliance standards – support FDA, HACCP, GMP, ISO 22000

✓ Lowest cost ownership – minimal total costs for life cycle

Ideal spheres application:

- Food industry and production beverages

- Pharmaceutical production

- Electronic industry

- Medicine and dentistry

- Textile industry

- Painting and coatings

- Laboratories and research centers

- Any productions, where purity air – critical factor

Range application: from small production lines to complex multi-compressor systems with possibility stage expansion.

Support: global service network Gardner Denver, programs maintenance PureCare, remote diagnostics iConn, training personnel.

Investing in EnviroAire VS, you receive not simply compressor, but complex solution for provision your production cleanest compressed air at minimal operational costs. This choice professionals, who understand importance quality, reliability and economic efficiency.

Gardner Denver EnviroAire VS – clean air for your success!

Main attributes Single Stage Variable Speed Water Injected Oil-Free Air Compressor Gardner Denver EnviroAire 15 A35004105W

Reviews about Single Stage Variable Speed Water Injected Oil-Free Air Compressor Gardner Denver EnviroAire 15 A35004105W

There are no reviews for this product.

Questions and Answers (FAQ) Single Stage Variable Speed Water Injected Oil-Free Air Compressor Gardner Denver EnviroAire 15 A35004105W